Nitrogen oxides (NOx), comprising nitric oxide (NO) and nitrous oxide (N2O), are notorious pollutants produced during various industrial processes. These gases are not only detrimental to human health, causing respiratory issues and contributing to air quality deterioration, but they also pose significant environmental threats. For instance, nitric oxide plays a pivotal role in forming acid rain while nitrous oxide—a potent greenhouse gas—affects climate change dramatically, contributing nearly 300 times more to global warming than carbon dioxide. The urgent need to mitigate these emissions has led to the utilization of zeolite-based catalysts, which have shown promise in converting these toxic gases into harmless byproducts. Recent findings from researchers at the Paul Scherrer Institute (PSI) in collaboration with the Swiss chemical company CASALE SA have shed light on the intricate workings of these catalysts.

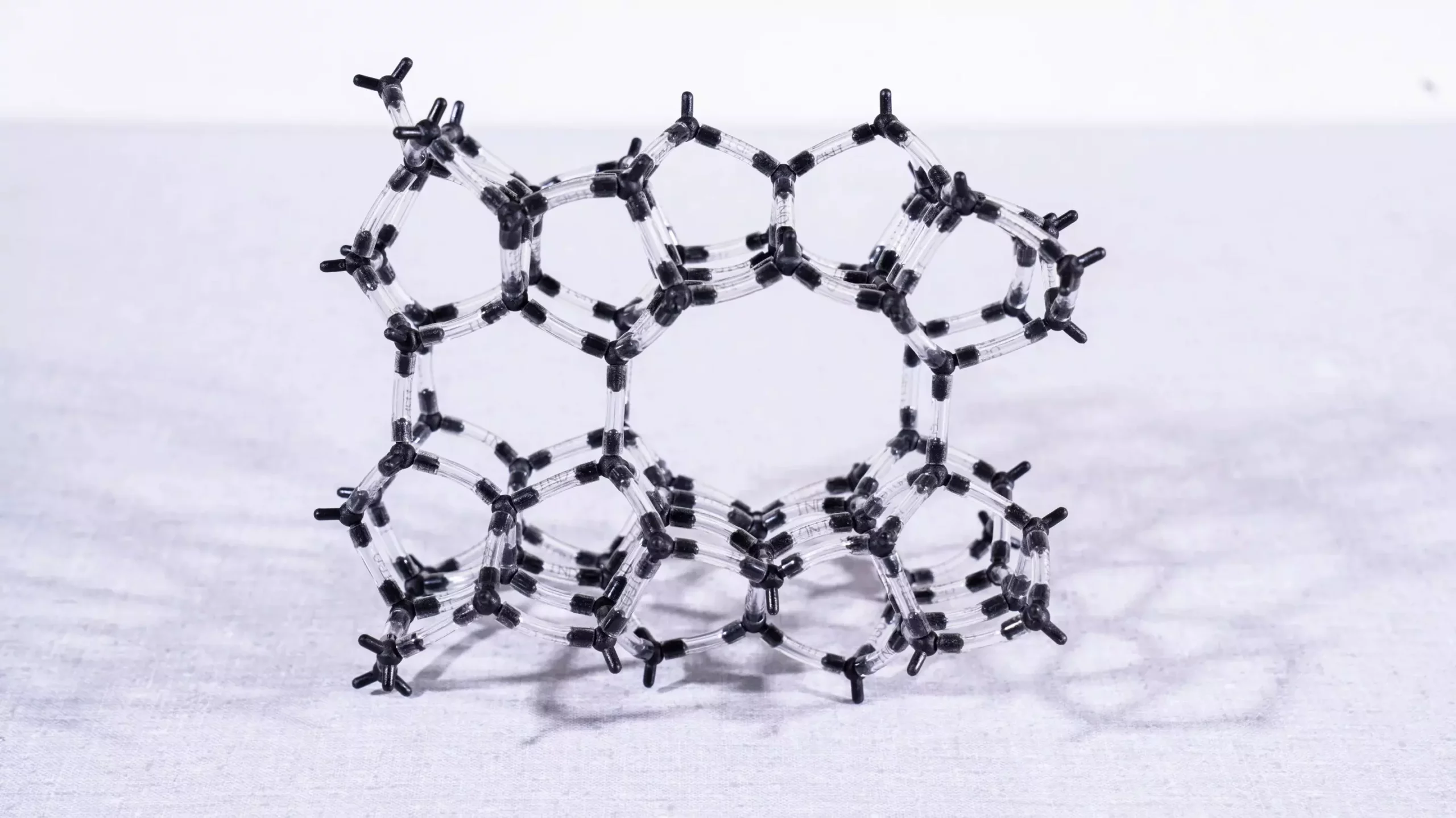

Zeolites are crystalline, nano-porous materials composed primarily of silicon, aluminum, and oxygen. Naturally occurring in geological formations or manufactured synthetically, zeolites serve as a versatile platform for catalytic reactions. In the context of NOx reduction, zeolites can be doped with iron, which acts as the active site for catalysis. This inclusion of iron into the zeolitic framework is crucial because it allows for the conversion of harmful nitrogen oxides into benign products. However, the performance of these catalysts stems from the varied configurations of iron atoms within the zeolite matrix, which can significantly differ in their catalytic abilities.

The complexity of zeolite catalysts arises from the diverse arrangement of iron within their structure. Researchers identified that iron can manifest as isolated single atoms or as clusters comprising multiple iron atoms intertwined with oxygen. This variety in iron configurations creates a “zoo” of iron species, each potentially contributing differently to the catalytic process. The PSI research team, led by Filippo Buttignol, aimed to pinpoint which specific iron configurations were most effective in catalyzing the reduction of NOx gases. The quest to unravel this mystery not only informs current applications but also guides future advancements in catalyst design.

To dissect the role of different iron species during the catalytic process, the researchers employed three sophisticated spectroscopic techniques. Initially, they harnessed X-ray absorption spectroscopy at the Swiss Light Source (SLS) to examine all iron species concurrently while the catalytic reactions occurred. This allowed them to obtain a comprehensive view of the active participants in the process. Furthermore, the collaboration with ETH Zurich enriched their analysis with electron paramagnetic resonance spectroscopy, which played a key role in attributing the contributions of each iron species to the catalytic reaction. Finally, infrared spectroscopy was utilized to evaluate the molecular interactions at play. Each method provided critical insights, weaving together a coherent narrative regarding the functionality of the zeolite catalysts.

The culmination of these experimental efforts revealed a striking mechanism for the simultaneous conversion of nitric oxide and nitrous oxide. It was found that only specific arrangements of iron atoms within the zeolite framework facilitated this reaction. One iron atom, positioned in a square formation surrounded by four oxygen atoms, focused on the reduction of nitrous oxide, while its neighboring iron atom, encased in a tetrahedral oxygen configuration, handled nitric oxide. This cooperative interaction between the two iron species enables a continuous catalytic cycle driven by a redox reaction, wherein each atom alternately donates and accepts electrons. This collaborative behavior underlines the precise nature of the zeolite catalysts, confirming that the architecture of the catalyst is fundamental to its ability to eliminate harmful gases simultaneously.

Understanding the specific sites and arrangements of iron that drive the desired reactions presents a unique opportunity for optimizing zeolite-based catalysts. As Davide Ferri noted, knowing the exact locations of catalytic activity allows for more effective tailoring of catalyst manufacturing, potentially enhancing efficiency and reducing costs. This knowledge could lead to the development of next-generation catalysts that are more selective and faster, further advancing industrial processes to be more environmentally friendly. As the world grapples with increasingly stringent emission regulations, the insights gained from this research are not just academic; they are crucial for the sustainable future of industrial operations.

The discoveries made by the team at PSI represent a significant leap forward in the quest to combat nitrogen oxide emissions. By unraveling the complex interactions of iron atoms within zeolite catalysts, they have laid the groundwork for both immediate practical applications and long-term innovations in catalytic technology. As industries increasingly prioritize environmental responsibility, the advancements in zeolite catalysis will play an instrumental role in striving for cleaner air and a healthier planet.

Leave a Reply