Dr. Sung Mook Choi of the Korea Institute of Materials Science and his research team have achieved a groundbreaking development in electrode fabrication. They have successfully created a one-step electrode fabrication process for the first time in South Korea, as detailed in the journal Applied Energy. This innovative process allows for the direct production of electrodes, crucial components of anion exchange membrane water electrolysis, from raw materials to a mass-producible scale.

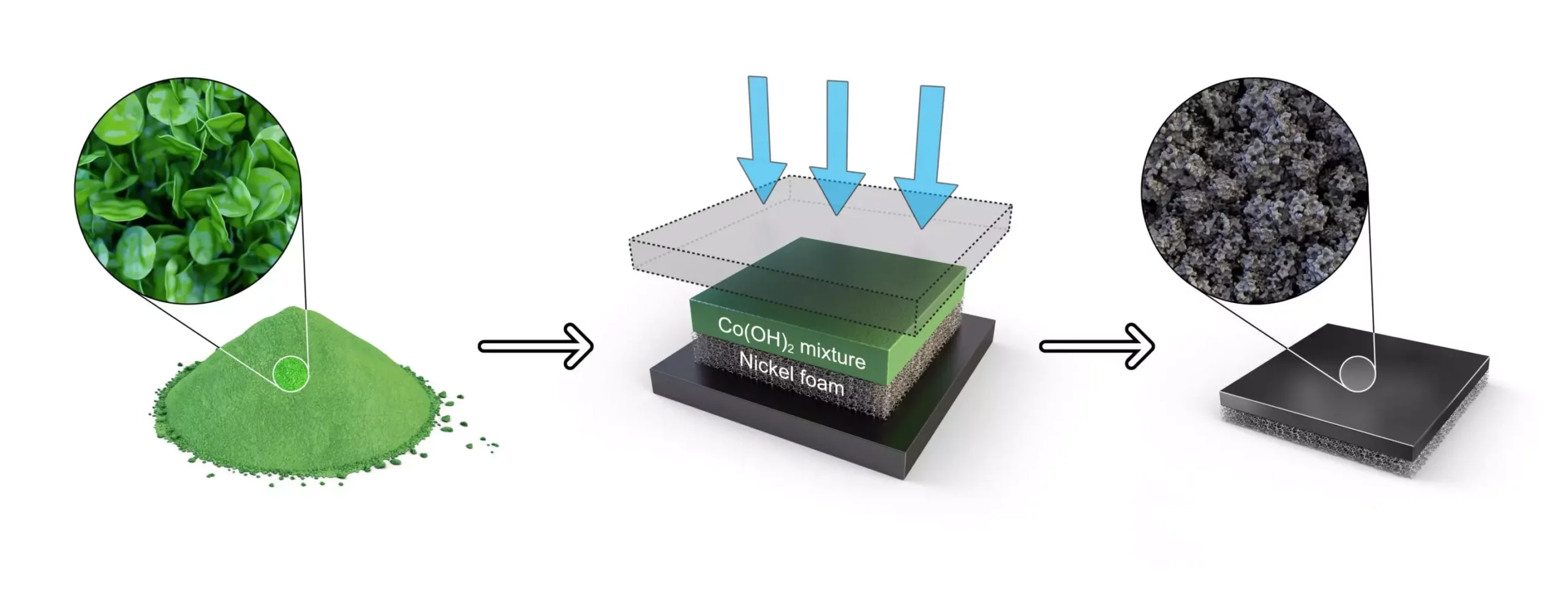

The technology introduced by the research team utilizes a one-step hot-pressing process that transforms cobalt hydroxide into a cobalt oxide catalyst while simultaneously forming a highly uniform catalyst layer. By streamlining the existing cumbersome process into a single coating step, significant advancements have been made. This new method reduces the complexity of the process by 60% compared to traditional methods, enabling the creation of a uniform catalyst layer. Not only does this simplify the manufacturing process, but it also enhances the efficiency of hydrogen production and improves the durability during continuous operation.

In order to optimize the one-step electrode fabrication process, the research team meticulously fabricated a catalyst layer consisting of uniform oxide particles, each measuring 10 nanometers in size. This was achieved by carefully controlling the cobalt hydroxide slurry conditions, as well as the temperature and pressure parameters crucial in the hot-pressing process. Furthermore, this developed electrode was utilized to create a membrane electrode assembly (MEA) that incorporated an anion exchange membrane and a hydrogen evolution catalyst, demonstrating stability and performance in a commercial-scale water electrolysis cell.

The implications of this breakthrough technology are far-reaching. Green hydrogen production from water electrolysis is expected to significantly increase by the year 2030, with projections reaching 11 million tons and 69 gigawatts of capacity. In Korea, efforts are already underway to develop technology for a megawatt-level anion exchange membrane water electrolysis system by 2024, with aims to commercialize such systems by 2030. At present, the domestic level of anion exchange membrane water electrolysis technology in Korea stands at approximately 70-80% of world-class standards, signaling a need for increased investments in related fields and the localization of technology.

Dr. Sung Mook Choi, the principal researcher behind this groundbreaking development, emphasized the importance of this achievement in advancing the commercialization of anion exchange membrane water electrolysis. By successfully developing a one-step hot pressing electrode fabrication process with high process reliability, the team has addressed a key challenge in this field. This technology not only paves the way for enhanced efficiency and durability in hydrogen production but also positions South Korea to secure a global edge in related technologies and dominate overseas water electrolysis markets. Through continuous innovation and development in this area, the promise of a sustainable and efficient hydrogen production future becomes increasingly feasible.

Leave a Reply