Traditional synthesis methods have long been plagued by various challenges when it comes to creating complex structures such as 1,2-arylheteroaryl ethanes. These challenges include reliance on pre-functionalized synthons, lengthy synthetic routes, limited substrate compatibility, and demanding reaction conditions. Despite the potential of these compounds for pharmaceutical applications, the obstacles in traditional synthesis methods have hindered their widespread use in drug development.

Basic feedstock chemicals such as ethylene, arenes, and heteroarenes play a crucial role in the modular synthesis approach developed by chemists at the National University of Singapore (NUS). These fundamental chemicals serve as building blocks for creating a diverse range of molecular structures specifically tailored for drug development. By harnessing these feedstock chemicals, researchers can explore new synthetic pathways and improve chemical reactions, ultimately advancing organic synthesis in pharmaceuticals.

A Breakthrough Approach

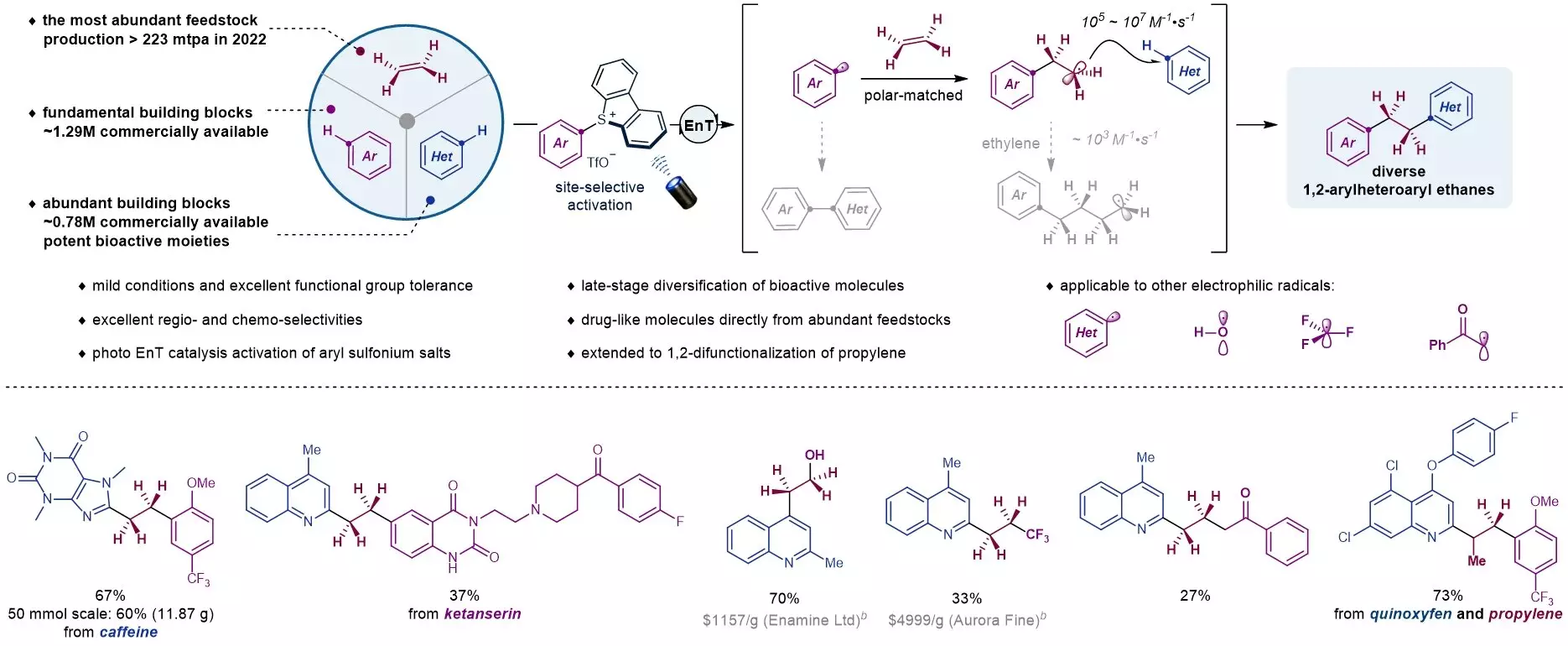

Associate Professor Wu Jie and his research team from the Department of Chemistry at NUS have introduced a groundbreaking approach to creating 1,2-arylheteroaryl ethanes. This innovative method utilizes light to initiate the generation of aryl radicals from aryl sulfonium salts, which are reactive intermediates involved in many organic reactions. These aryl radicals then react with ethylene and heteroarenes molecules to produce the desired chemical compounds. This novel approach not only simplifies the synthesis of 1,2-arylheteroaryl ethanes but also enables the production of other valuable fine chemicals using different radical precursors and gaseous alkenes.

The modular synthesis approach developed by the NUS research team has the potential to revolutionize the drug discovery and petrochemical industries. By utilizing gaseous alkenes and coupling multiple fundamental components, this method enables the sustainable and modular production of diverse molecular scaffolds. This advancement could have far-reaching implications for the development of new pharmaceuticals and fine chemicals, paving the way for more efficient and sustainable production processes in these industries.

The research team at NUS has also implemented a simple in-house built circulation flow system to add practicality to their synthetic protocol. This system enhances the efficiency and effectiveness of the modular synthesis approach, making it more feasible for large-scale production of valuable fine chemicals. Professor Wu Jie emphasized the team’s commitment to developing innovative strategies for synthesizing fine chemicals from basic feedstock chemicals, highlighting the potential of this approach for on-demand assembly of valuable compounds.

Leave a Reply