The fashion industry has witnessed a surge in the production of fast fashion over the past few decades. This has led to a significant challenge in recycling textiles due to the use of multiple types or blends of fibers in clothes. Conventional methods of recycling often fall short when it comes to efficiently and inexpensively separating these fibers to facilitate the recycling process.

A team of chemical and biomolecular engineers has developed a revolutionary method to chemically separate fibers in textiles, making the recycling process quicker and more cost-effective. By using a solvent to break the bonds holding polyester together with other materials like nylon or cotton, the researchers have found a way to accelerate the bond-breaking process. The addition of zinc oxide as a catalyst, along with the application of heat in a microwave oven, has proven to be highly efficient in breaking apart textiles in as little as 15 minutes.

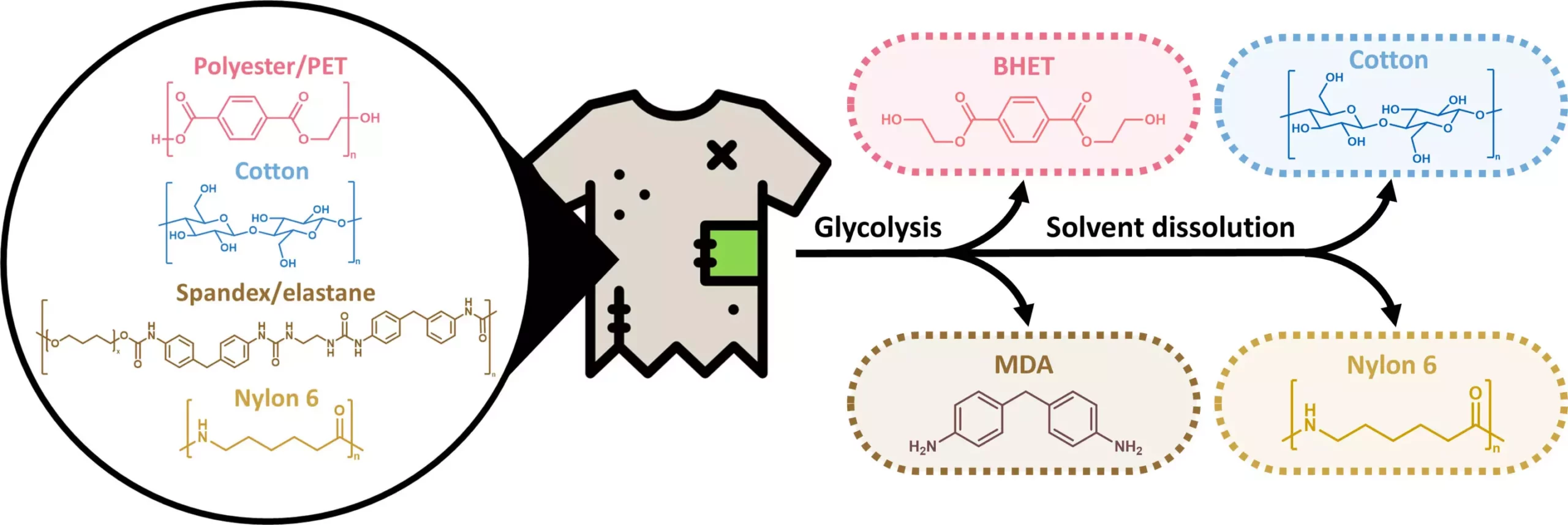

The innovative process not only releases nylons, cottons, and other materials but also breaks down polyester into BHET and spandex into monomers. BHET, an organic compound, shows promise in being repurposed to create more polyester. Testing conducted on polyester/cotton and spandex/nylon blends has shown that the material integrity of both nylon and cotton remains intact, indicating the potential for these materials to be used in the production of new clothing batches.

Despite the promising results, the researchers noted that flame retardant chemicals present in some clothes could impede the recycling process. Therefore, the removal of these chemicals would be necessary before recycling. Additionally, the study includes mathematical models demonstrating the economic viability of this innovative recycling method for textiles.

The development of this novel technique in textile recycling opens up new possibilities for the fashion industry to move towards a more sustainable and environmentally friendly approach. By addressing the challenges posed by fast fashion and complex fiber blends, this breakthrough has the potential to revolutionize the way clothes are produced, reused, and recycled.

Leave a Reply