The research conducted by Dr. Winston “Wole” Soboyejo and Dr. Tabiri Kwayie Asumadu at SUNY Polytechnic Institute has significant implications for various industries. The paper titled “Robust Macroscale Superlubricity on Carbon-Coated Metallic Surfaces” explores a groundbreaking approach to reducing friction on metallic surfaces. This innovative method could potentially have major real-world impacts, especially in sectors such as automotive, manufacturing, and electronics.

The study reveals that superlubricity, a state with virtually no friction that was once considered achievable only at the nanoscale, can now be maintained at macroscale for extended periods under regular atmospheric conditions. This achievement is made possible through the utilization of sustainably produced carbon coatings derived from biowaste. The findings are particularly significant given the potential to improve fuel efficiency in the automotive industry, reduce wear and tear in manufacturing machinery, and address friction-related challenges in electronic devices.

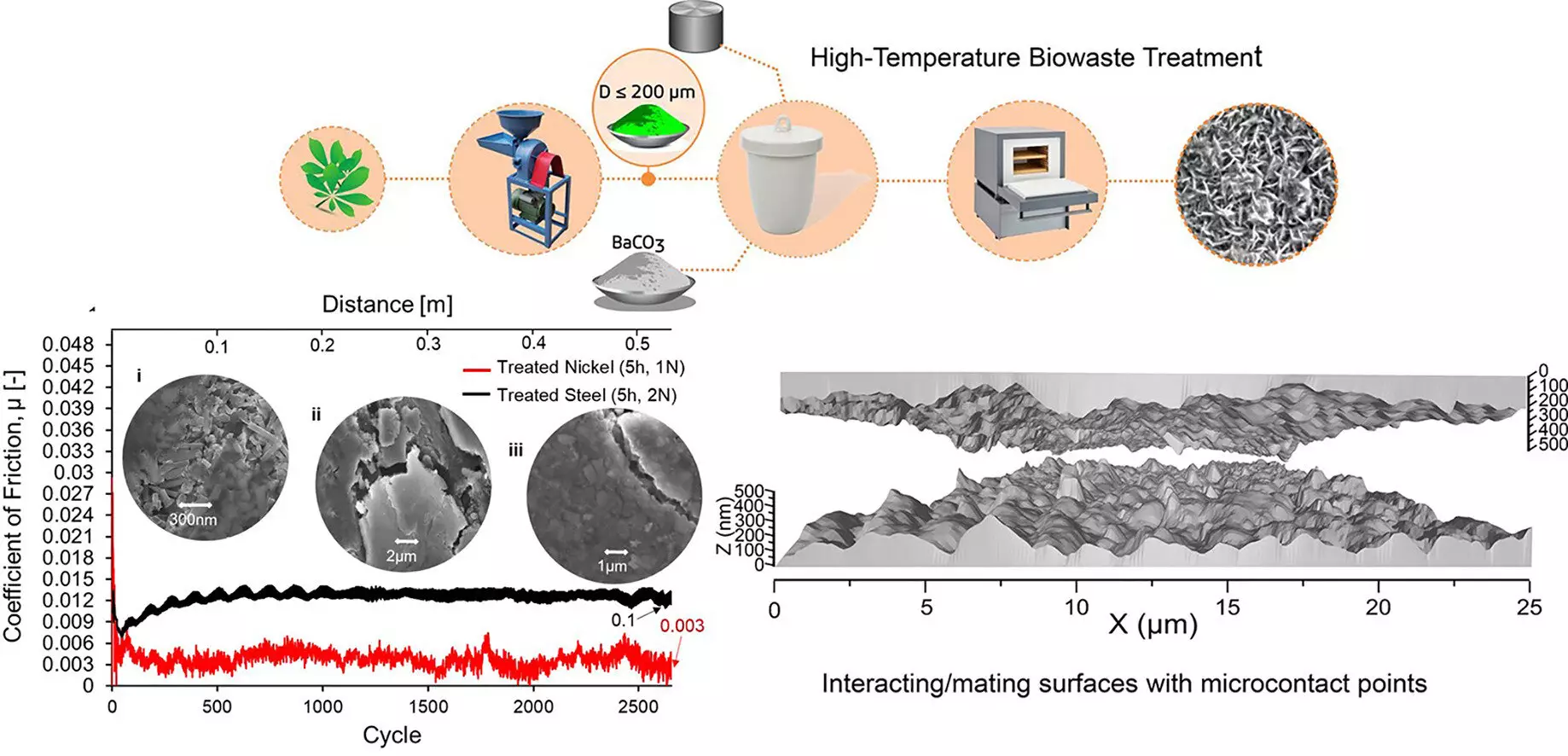

The research presents experimental and computational data showcasing ultralow friction levels of carbon-coated metallic depositions on substrates such as structural steels, Ti, and Ni alloys. The macroscale superlubricity demonstrated in the study was sustained over multiple cycles by utilizing structurally misoriented carbon coatings on the metallic surfaces. By depositing carbon nanocrystals with graphene footprints on these surfaces through a high-temperature biowaste treatment process, the researchers were able to achieve a superlubricious coefficient of friction of approximately 0.003. The carbon nanocrystals deformed, flattened, and merged in the wear tracks to form graphitic films, leading to reduced wear rates and a coating life of around 150,000 cycles on Ni and steel substrates.

The experiments were supported by atomistic simulations that provided a deeper understanding of the impact of graphene variants on the observed frictionless conditions. The study elucidates the underlying mechanisms of coating/substrate interactions that contribute to macroscale superlubricity, paving the way for designing robust and cost-effective carbon coatings on metallic surfaces. The use of biowaste as a carbon source aligns with the principles of a circular economy, promoting material recycling and reducing the global carbon footprint. The collaborative effort involved eight materials scientists from Africa and the Northeastern United States, highlighting the importance of international cooperation in advancing sustainable technologies. Dr. Soboyejo emphasized the environmental and economic implications of the research, expressing pride in the team’s accomplishments.

Overall, the research on superlubricity using sustainable carbon coatings represents a significant step towards enhancing efficiency, reducing costs, and promoting environmental sustainability across various industries. By harnessing the potential of biowaste-derived materials and innovative coating techniques, the study opens up new possibilities for extending the lifespan of machine parts, minimizing maintenance expenses, and creating a more sustainable industrial future.

Leave a Reply