Green hydrogen is emerging as a beacon of hope for our transition to a sustainable energy future. As nations worldwide grapple with the escalating climate crisis, the production of low-cost, renewable hydrogen energy is increasingly being recognized as a critical strategy toward achieving net-zero carbon dioxide emissions. The U.S. Department of Energy has set ambitious targets, and to meet them, innovative technologies that simplify the process of converting water into hydrogen and oxygen are imperative. A recent study delivered significant breakthroughs in this field, indicating that a novel approach using defect engineering in catalysts can dramatically enhance the efficiency of hydrogen production from water, paving the way for widespread adoption of green hydrogen technologies.

The Mechanics of Electrochemical Hydrogen Production

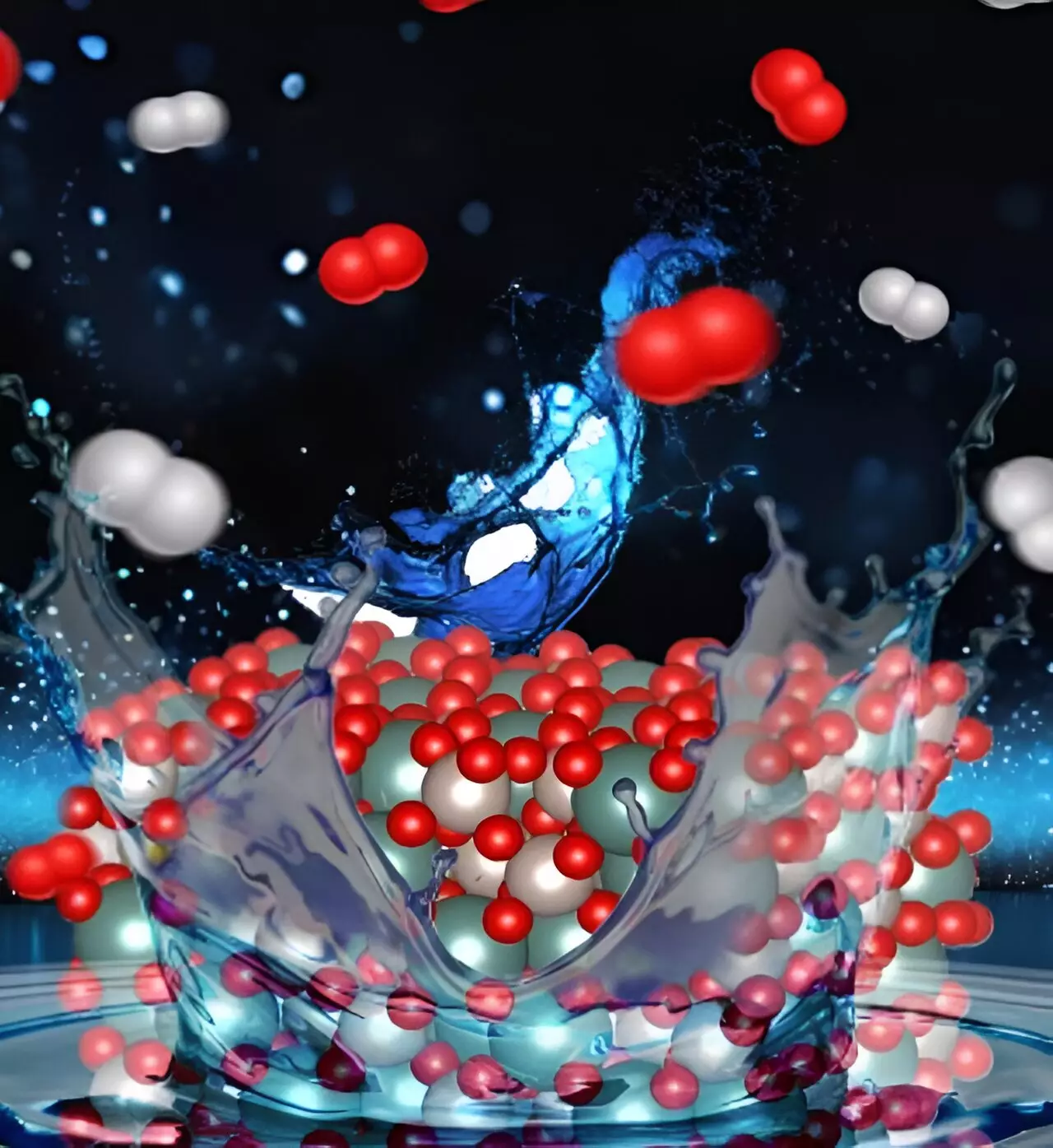

At its core, the process for generating hydrogen from water involves electrochemical reactions that enable the separation of water molecules into hydrogen and oxygen. Current techniques predominantly rely on devices like proton exchange membrane electrolyzers, which employ two electrodes—one serving as a cathode to collect hydrogen, and the other as an anode to release oxygen. However, a pivotal challenge exists: the generation of oxygen is inherently slower than that of hydrogen. This discrepancy limits overall production rates, creating a bottleneck in the hydrogen extraction process. Unlocking this challenge through the advancement of catalysis is key to scaling green hydrogen production to industrial levels.

The Role of Defect Engineering in Catalysis

The recent advancements reported in the Journal of the American Chemical Society highlight a groundbreaking approach wherein researchers have manipulated the electronic configurations of catalysts through defect engineering. Led by Professor Hong Yang, a team of interdisciplinary experts used ruthenium as a base to develop a new oxides-based electrocatalyst. The innovative twist? By intentionally introducing yttrium atoms into the ruthenium structure, they created what is termed a “defective” catalyst, which, contrary to traditional design paradigms, enhanced the material’s efficiency in generating oxygen.

This concept closely mirrors practices in semiconductor technology, where introducing specific impurities into silicon amplifies performance. Professor Yang’s findings suggest that the introduction of defects, if executed with precision, can optimize catalytic processes in ways previously underestimated by the scientific community.

Exploring the Catalytic Advantages

One of the most fascinating aspects of this study is the discovery that oxygen generation was significantly enhanced without altering the total oxygen concentration within the catalytic material. Instead, it was the transformation of the oxidation state—the charge distribution of the metal atoms—that improved performance. Graduate student Bidipta Ghosh’s observation that higher activity emerged not from increased oxygen quantity but from refined electronic structure is an exceptionally nuanced understanding of catalytic efficiency.

The implications for future research are profound; rather than simply focusing on the quantity of reactive elements, scientists should emphasize their electronic configurations and how they interact within their environments. This provides a fertile ground for innovative strategies pushing towards even greater efficiencies in the quest for green hydrogen.

Collaboration: The Heart of Innovation

What stood out most in this research was the collaborative nature of the project, where experts from various scientific disciplines came together to address complex challenges. As articulated by Yang, multi-faceted approaches are essential for overcoming the technical hurdles associated with understanding catalyst performance. This teamwork not only facilitates knowledge sharing but fosters an environment where experimental insights can inform theoretical frameworks, thus driving fields like catalysis towards tangible advancements.

Moreover, such interdisciplinary collaboration is a model for future endeavors in clean energy technologies. The synthesis of chemistry, engineering, and materials science could prove instrumental in accelerating breakthroughs necessary to enable the widespread application of hydrogen as a clean energy source.

The innovative strides made through defect engineering in electrocatalysts symbolizes a pivotal moment in the field of green hydrogen production. The ability to enhance catalytic efficiency while adhering to principles recognized in other technology domains, such as semiconductor manufacturing, reveals the potential for significant advancements toward sustainable energy systems. As researchers continue to unravel the complexities of efficient hydrogen production, the pathway to achieving clean energy could become clearer, sustainable, and exponentially more effective. The intertwined effort of scientific disciplines only enhances the prospects of a cleaner, greener future powered by hydrogen.

Leave a Reply