Ethylene, a highly flammable compound with a wide range of applications, is currently produced primarily through fossil-powered steam cracking of ethane. This traditional method is not only energy-intensive but also contributes to the greenhouse gas emissions. However, researchers from Soochow University, University of Toronto, and other institutes have introduced a new approach to producing ethylene. This method involves the solar-powered photocatalytic dehydrogenation of ethane using the perovskite oxide LaMn1−xCuxO3.

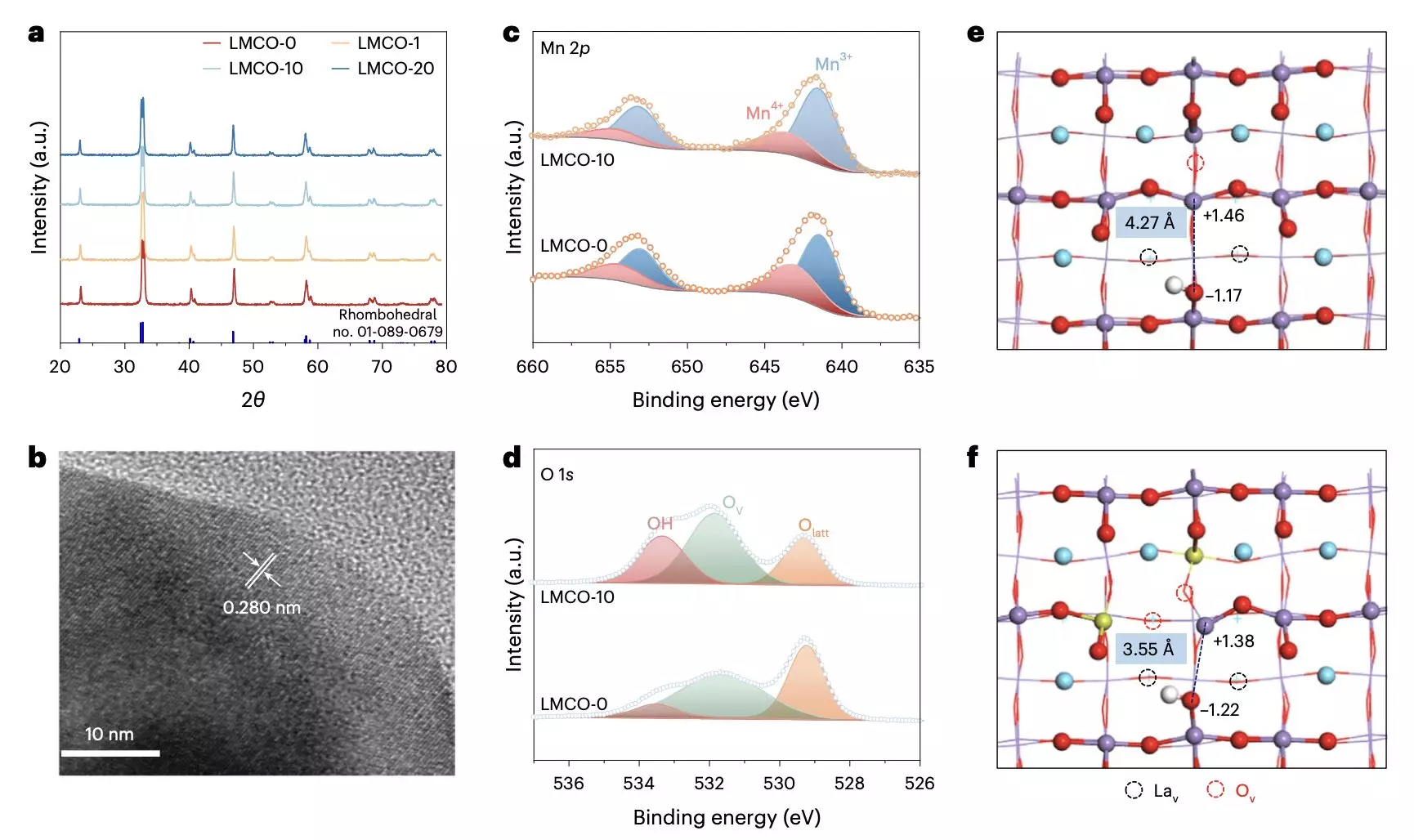

The perovskite oxide LaMn1−xCuxO3 is a promising selective photocatalyst for converting ethane into ethylene and hydrogen using solar or LED light. With redox-active Lewis acid and base sites, this compound eliminates the need for external heat sources, making it an environmentally friendly option for ethylene production. By tuning the proportions of these sites, researchers were able to optimize the activity, selectivity, and yield for ethane dehydrogenation.

Through rooftop prototype testing, researchers achieved remarkable ethylene production rates using the LaMn1−xCuxO3 perovskite oxide. Furthermore, comprehensive technical and economic analyses revealed the significant economic potential of this solar-powered approach. With ethylene production rates of up to 1.1 mmol g−1 h−1 and an ethane conversion rate of 4.9%, the viability of industrial-scale solar ethylene production is evident.

Future Research Directions

To further enhance the efficiency of the ethylene production process, researchers plan to engineer the photocatalyst and photoreactor for maximum light absorption and minimal losses. Additionally, future studies will focus on improving photochemical activation, light capture, and light transport rates to boost the overall photocatalytic efficiency of the LaMn1−xCuxO3 perovskite oxide.

The development of a solar-powered approach to ethylene production represents a significant step towards a more sustainable future. By utilizing the unique properties of the LaMn1−xCuxO3 perovskite oxide, researchers have demonstrated a feasible alternative to traditional ethylene production methods. With further research and technological advancements, this innovative approach has the potential to revolutionize the large-scale production of ethylene while reducing carbon emissions and mitigating environmental impact.

Leave a Reply