The rapid adoption of electric vehicles (EVs) in the transportation sector is reminiscent of a technological revolution, aiming to reduce carbon footprints and promote sustainability. However, one significant challenge impeding this transition is the limited lifespan and performance of current battery technologies. Recognizing this issue, researchers are exploring innovative solutions, notably the concept of structural batteries. These pioneering systems promise to merge the functionalities of energy storage and structural integrity, providing a dual-purpose component that could transform the design and efficiency of electric vehicles and beyond.

Structural batteries are distinctive in that they do not merely serve as energy storage units; they can be integrated into the very structure of a vehicle or device. This integration allows batteries to be more than just bulky external components; they become functional parts of the overall architecture, enhancing both weight optimization and efficiency. Researchers have focused on creating structural batteries that are lightweight yet robust, enabling vehicles to achieve longer travel ranges while minimizing energy loss. By allowing structural elements to double as energy storage, designers can significantly reduce material requirements, boosting both performance and sustainability.

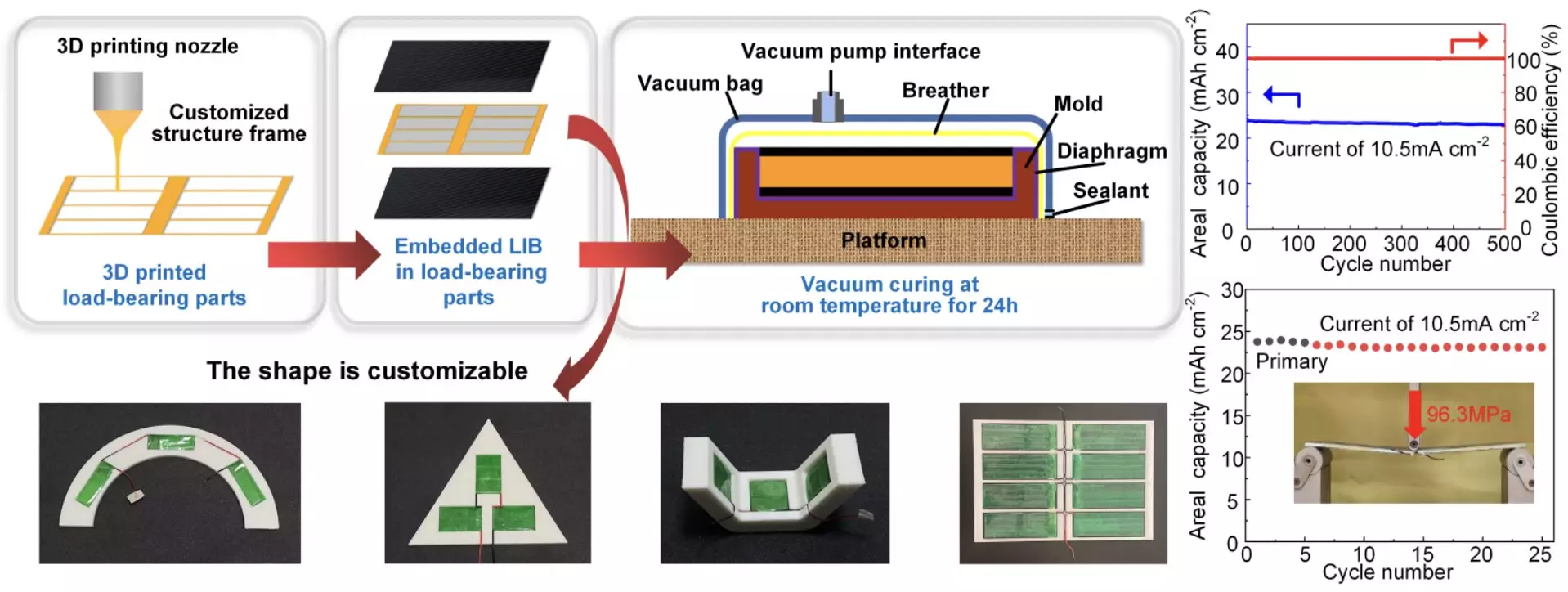

The research conducted by a team from Shanghai University showcases a groundbreaking strategy involving 3D printing technology. By customizing geometric configurations of structural lithium-ion batteries, this approach aims to take full advantage of the structural integrity while enhancing energy storage capabilities. According to Yinhua Bao, a leading researcher on the project, the intent is to craft integrated systems with high durability and significant energy-retaining capacity. This dual functionality can significantly alter the landscape of electric vehicle design, making them lighter and more efficient.

At the forefront of this technological advancement is the use of 3D printing, a methodology that has revolutionized manufacturing across various sectors. The application of 3D printing in the fabrication of structural batteries allows for precise control over the designs and materials used, yielding customizable solutions that can be tailored for specific applications. For instance, by selecting appropriate materials for the battery electrodes and frameworks, researchers can enhance overall performance and operational capacity.

The design principle of decoupling, discussed by Bao, is crucial in this context. By creating a battery structure that maintains the components’ integrity under stress, researchers can mitigate damage that typically arises from mechanical loads. This innovation is essential for ensuring that structural batteries maintain their energy storage capabilities even when subjected to external pressures.

Furthermore, the capacity to simulate stress through finite element analysis aids in refining structural designs to minimize potential failure points. This proactive approach ensures that the distributed arrangement of battery cells helps protect against localized damage, enhancing the reliability of the entire system.

The initial tests conducted on the newly designed composite structural battery reveal promising outcomes. Notably, the battery demonstrated impressive resilience against both tensile and bending stresses while maintaining a high energy density. With test results indicating a retention of 92% of its capacity after 500 cycles, and negligible capacity loss under significant stress, the implications for the electric vehicle industry and other sectors appear remarkable.

Moreover, the versatility of this technology means that it can also be harnessed for applications beyond electric vehicles, including drones, autonomous robots, and even logistics systems. The notion of adaptable energy storage solutions allows manufacturers to explore novel designs tailored for emerging technologies that require compact and lightweight energy sources. This capability could lead to profound shifts in how we think about energy storage systems.

In a forward-thinking context, researchers plan to delve deeper into the application of these structural batteries for a variety of emerging technologies, including unmanned aerial vehicles (UAVs) and robotic systems. The potential for extensive innovations signals a future where vehicles are not only powered by integrated batteries but are also structurally reinforced by them.

The development of structural batteries signifies a significant leap in energy storage technology, demonstrating the potential to transform various industries by integrating energy functions with structural components seamlessly. As researchers continue to refine their designs and improve performance metrics, the shift toward structural batteries could pave the way for a new era in electric vehicle manufacturing and other fields requiring advanced energy solutions. With their ability to enhance both efficiency and durability, structural batteries may just be the key to unlocking the full potential of electric transportation and beyond, driving us toward a more sustainable future.

Leave a Reply