Rare earth elements (REEs) have been deemed as “critical minerals” by the U.S. Department of Energy due to their niche uses in modern electronics. Chemistry professor Justin Wilson from UC Santa Barbara sheds light on the significance of dysprosium, a lesser-known element categorized under the REEs. While elements like platinum or gold are rarer, REEs pose a challenge in extraction and purification due to their hidden placement in the periodic table and similar chemical properties. The difficulty in isolating REEs from natural deposits has led Wilson and his team to develop innovative techniques for purification at room temperature without the use of toxic compounds.

The current industry standard for separating REEs involves liquid-liquid extraction using organic solvents and water-based solvents. This method, akin to salad dressing with two immiscible phases, relies on chelators to bind to REEs based on size differences. However, the conventional process is inefficient, generating chemical waste and requiring multiple extraction cycles to obtain pure samples for industrial use. Wilson’s team, in collaboration with researchers from Cornell and University of Nevada, Reno, improved upon existing chelators and designed a solvent-free process that eliminates flammable and toxic substances.

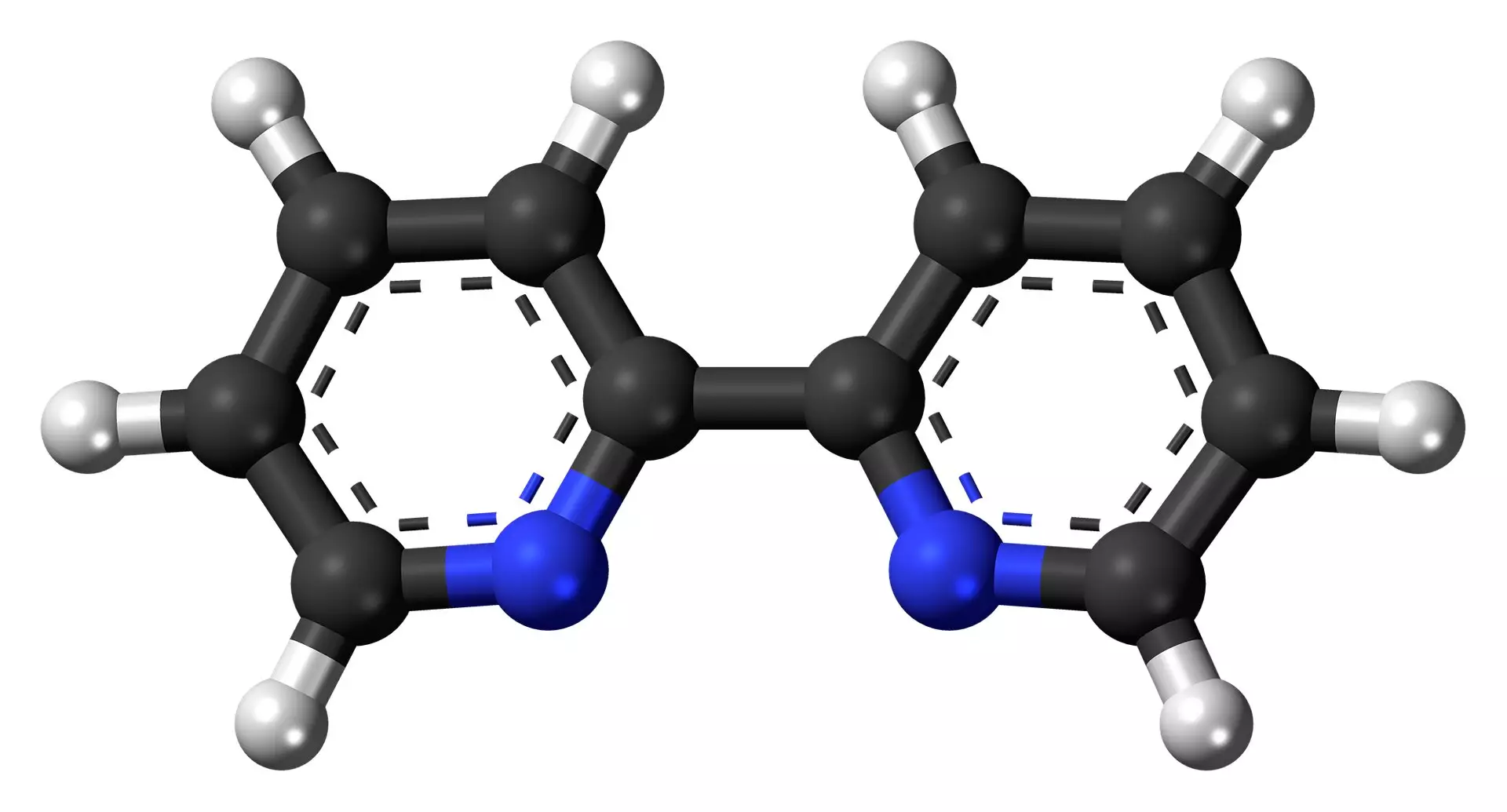

By utilizing a specific chelator called G-macropa, the researchers were able to precipitate dysprosium from a mixture containing neodymium. The addition of sodium bicarbonate caused dysprosium to form a carbonate salt, which could be easily filtered and processed for metal recovery. Unlike traditional methods, this new process demonstrated a significant increase in concentration, with a single cycle enriching dysprosium by a factor of over 800. The team’s innovative approach not only enhances the efficiency of REE separation but also reduces environmental and health risks associated with conventional techniques.

The successful separation of neodymium and dysprosium from electronic waste highlights the potential for sustainable recycling practices to meet the growing demand for REEs. Wilson and his colleagues are exploring ways to adapt their technique for other rare earth element assemblages and industrial sources. This breakthrough not only paves the way for a cleaner and more efficient supply chain but also has implications for national security and economic competitiveness. With the possibility of opening up domestic supplies of rare earth elements, the United States could reduce its reliance on foreign sources and establish a more robust industry for these essential materials.

The research conducted by Wilson and his team represents a significant advancement in the field of rare earth element extraction and purification. By addressing the challenges associated with traditional methods, the new solvent-free process offers a safer and more sustainable approach to meeting the future demand for these critical minerals. As technology continues to advance and the need for rare earth elements grows, innovative solutions like this will play a crucial role in securing a stable supply chain and driving economic growth in the United States and beyond.

Leave a Reply