Traditionally, engineers and material scientists have regarded voids or pores within metallic structures as detrimental, compromising the mechanical integrity and performance of materials. Yet, recent advancements suggest this view might warrant reconsideration. Led by Prof. Jin Haijun at the Institute of Metal Research under the Chinese Academy of Sciences, a compelling body of research has emerged that highlights how the intentional incorporation of nanoscale voids can enhance material properties rather than diminish them. This revolutionary perspective urges us to rethink our fundamental approaches to material fabrication.

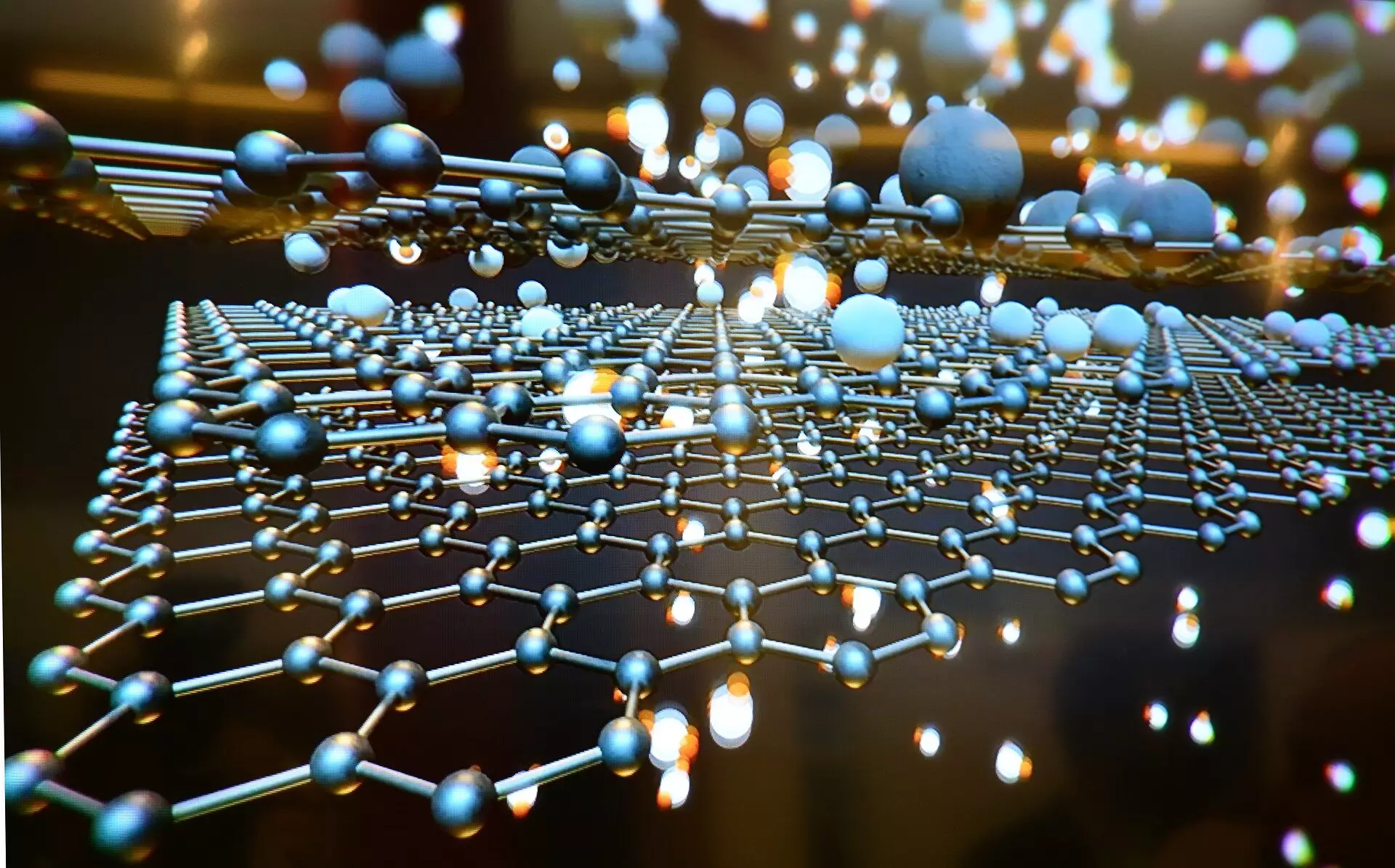

The research team has pioneered a new class of gold, termed nanovoid dispersed gold (NVD Au), which is remarkably distinct from its conventional counterparts. What sets NVD Au apart is its fine structure, characterized by numerous nanoscale voids—ranging from just a few nanometers to several hundred—uniformly integrated throughout the material. This innovation is not merely a superficial alteration; its formation involves a sophisticated synergy of dealloying processes, thermal treatments, and mechanical compression, culminating in a product that surpasses the limitations of regular gold.

The implications of NVD Au are significant, particularly in terms of mechanical performance. Researchers demonstrated that this newly developed material exhibits superior strength and ductility under tension compared to fully dense gold. In practical terms, this translates to a resistance to high loads and an increased capacity to be elongated without succumbing to fracture. These findings stand in stark contrast to conventional wisdom surrounding voids formed through techniques like powder sintering, which often lead to disadvantages due to the presence of larger voids.

The underpinning mechanisms that provide NVD Au with its enhanced properties stem from intricate interactions between dislocations and the surface of the material, coupled with a pronounced suppression of crack formation. Prof. Jin emphasizes that this approach allows for both an increase in strength and a reduction in overall material density, achieving a lightweight structure without altering the essential composition or phase of the material. Such preservation of the base properties is crucial, as it indicates the potential for a wide range of applications.

The implications of this discovery extend far beyond theoretical interest. The versatility of NVD Au opens the door for innovative applications ranging from portable electronics to aviation manufacturing, where lightweight, durable materials are increasingly important. The collaboration with experts from the Liaoning Academy of Materials and Nanjing University of Science and Technology further underlines the broad scientific support for this breakthrough. In essence, this research embodies a paradigm shift in how engineers conceptualize and leverage the inherent properties of materials.

As the field of material science continues to evolve, the narrative surrounding voids in metals is being rewritten. The integration of nanoscale voids, as illustrated by the remarkable properties of NVD Au, suggests that what was once viewed as a flaw could be harnessed as a valuable asset. This study not only opens new pathways for future research but also challenges the core principles of material selection and processing in various industrial applications. As we embrace these findings, the pursuit of innovative, efficient materials is more achievable than ever before.

Leave a Reply