Electric motors are an indispensable component of modern technology, powering everything from household appliances to sophisticated automotive systems. Though individually they may seem insignificant in terms of energy consumption, collectively, small electric motors have a substantial impact on energy efficiency and the overall power dynamics of various devices. This is especially significant in the context of our growing need for sustainable technologies. A recent initiative by a research team at Graz University of Technology seeks to harness the untapped potential of these small motors, paving the way for more efficient and quieter operations across various applications.

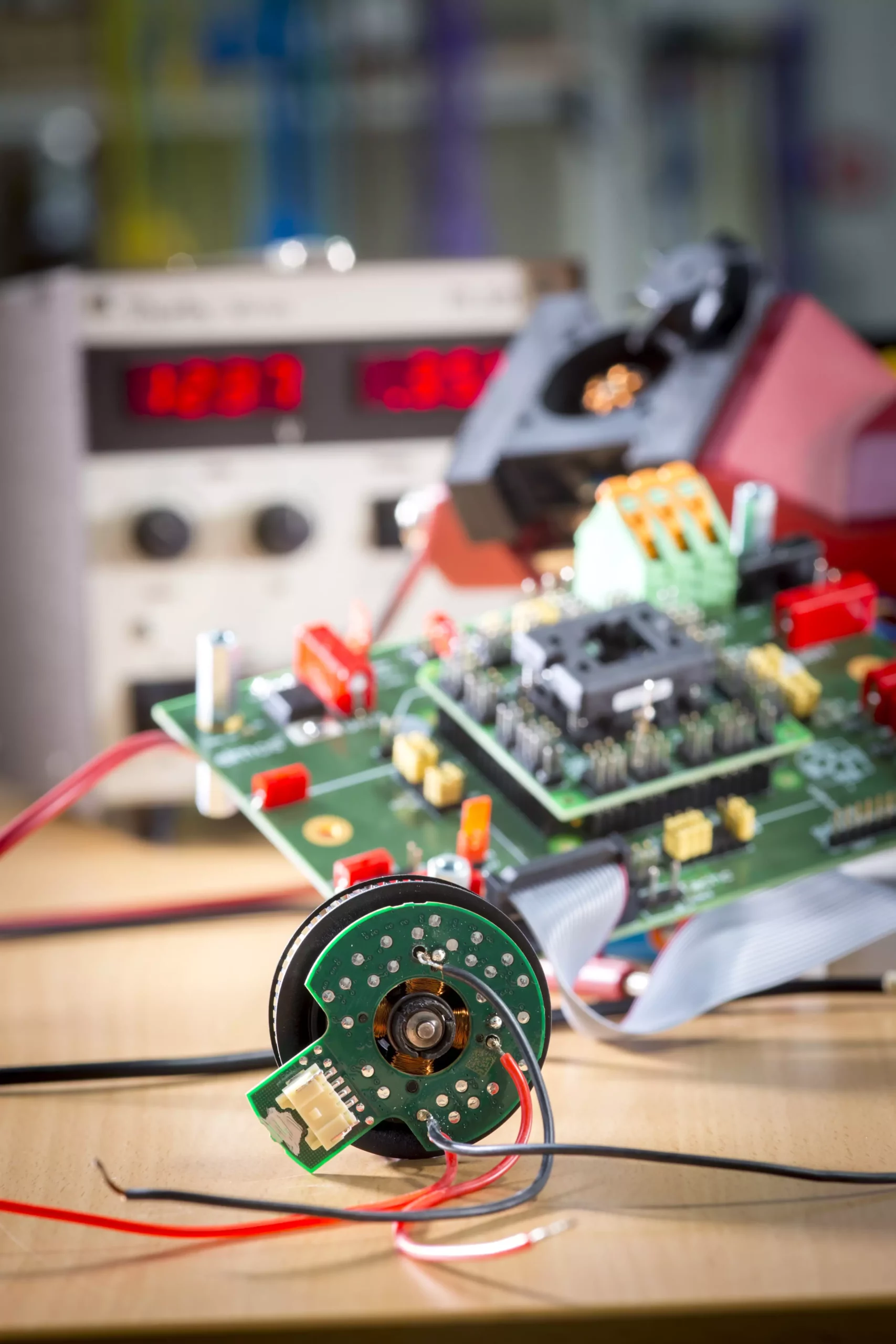

Under the leadership of Annette Mütze, the team at the Electric Drives and Power Electronic Systems Institute has focused on refining traditional brushless integrated drives. Their innovative approach integrates advanced design processes, modern control technologies, and novel manufacturing techniques. The result of their efforts is a line of brushless motors that not only consume less energy but also operate more quietly and with reduced weight, enhancing their utility in both industrial and consumer contexts.

One of the most significant challenges in electric motors is the phenomenon known as “cogging torque,” which can lead to vibrations and noise. To tackle this issue, Mütze’s team employed a strategy involving the alteration of the motor’s claw pole structure. By skewing and slotting the claws, they minimized the gripping force when the motor is activated, which drastically mitigates vibrations and noise levels. Such innovation has led to a 70% reduction in noise, greatly enhancing user experience in applications where silence is key, such as in residential settings and precise medical devices.

Another breakthrough of the Graz research team is the simplification of current flow regulation in brushless motors. Traditional pulse width modulation (PWM) techniques necessitate numerous switching operations to maintain the desired current flow, ultimately leading to higher energy expenditure due to inefficiencies. Mütze’s new design philosophy innovates on this by employing a simpler switching mechanism, activating the motors only once to achieve a defined current state. This results in a remarkable reduction of switching losses, allowing for increased energy efficiency—particularly at lower currents.

This enhanced efficiency contributes significantly to overall operational cost savings—an essential factor for both manufacturers and consumers. The team’s approach also has the ancillary benefit of reducing the number of required components in the motors. With fewer capacitors needed on the circuit boards, production costs diminish, making these innovative motors not only more efficient but also more economically viable to produce at scale.

In addition to improvements in energy efficiency and noise reduction, the Graz research team has developed Printed Circuit Board (PCB) motors, integrating the magnetic field windings directly into the circuit board format. This groundbreaking design facilitates a high degree of automation in manufacturing, which can increase output while reducing human error and production time. Coupled with 3D-printed ferrite cores, these PCB motors become more capable of channeling magnetic flux effectively, allowing for the incorporation of less expensive ferrite magnets without sacrificing performance.

By leveraging innovative design and the latest in manufacturing technology, the team has positioned these small electric motors as frontrunners in the future of efficient machinery. Their work exemplifies how integrated technological advances can yield significant gains in performance metrics previously thought difficult to achieve.

The research at Graz University of Technology illustrates a promising trajectory towards highly efficient electric motors that not only reduce energy consumption but also minimize noise and production costs. As the demand for efficient solutions grows in both consumer electronics and automotive industries, the innovative designs emerging from this research represent a crucial step forward. The collective developments in brushless integrated drives showcase a vital synergy between engineering, design, and sustainability that could redefine the future landscape of electric motor applications.

Leave a Reply