In the face of escalating electronic waste (e-waste) crises, particularly driven by rapidly advancing technology, a research initiative spearheaded by Rice University’s distinguished chemist James Tour has emerged as a beacon of hope. The new methodology promises not only to enhance the efficiency of metal recycling but also to greatly mitigate the environmental repercussions characteristically linked with traditional metal extraction processes. This advancement stands crucial in addressing two pressing global challenges: resource scarcity and environmental degradation.

The conventional practices employed in metal recycling—including hydrometallurgy and pyrometallurgy—frequently result in significant ecological harm. The reliance on energy-intensive procedures often forces the usage of acidic substances and generates hazardous waste, contributing to extensive soil and water pollution. As the global economy witnesses an insatiable demand for precious metals—components imperative for manufacturing electronic devices—the need for sustainable solutions is more urgent than ever. Tour’s pioneering work shifts the paradigm, aiming to reduce the extraction’s ecological footprint while simultaneously fulfilling the high demand for critical metals.

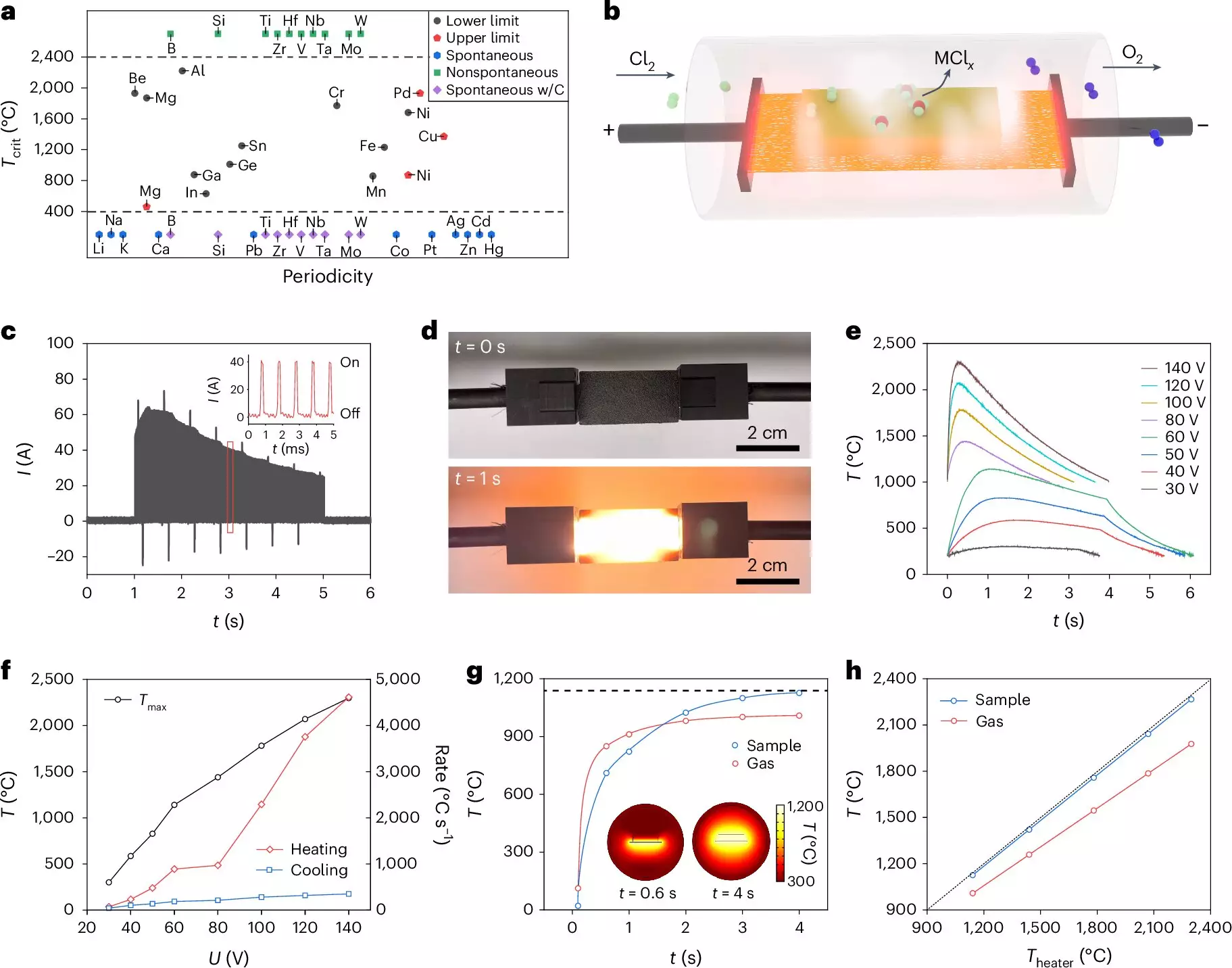

The research team has ingeniously refined the technique of flash Joule heating (FJH) to recover valuable metals such as gallium, indium, and tantalum from e-waste. FJH involves generating extreme temperatures through electric currents, thus triggering the breakdown of materials into their elemental constituents. This innovative method diverges from conventional approaches by employing chlorination and carbochlorination processes to recover metals with striking efficiency. Notably, the operational advantages include precise temperature management, which ensures controlled reactions that lead to remarkable purity levels of over 95% and yields exceeding 85%.

The ramifications of this advancement extend beyond merely improving recycling technologies; it provides a pragmatic incentive for enhancing the economic viability of recycling industries worldwide. With the looming crisis of critical metal shortages, the approach elucidated by Tour and his team could become instrumental in driving policy changes aimed at sustainable development. The researchers’ successful isolation of metals from electronic waste serves as a compelling model for industries grappling with similar environmental concerns.

Acknowledging future applications, the researchers express optimism about adapting their method for extracting lithium and rare Earth elements, which are equally vital for modern technological applications. The potential for this technique to scale and adapt positions it as a promising solution in a world increasingly dependent on electronics.

The advent of this new metal recovery method is commendable, yet it also serves as a clarion call for further investment in sustainable recycling technologies. As consumers and industries alike strive to reduce their carbon footprints and combat the implications of e-waste, the innovative solutions developed by Tour and his team might very well be the catalyst for broader changes in recycling practices and policies. Embracing this technology could redefine the relationship humanity has with its discarded electronics, heralding a new era of resource recovery and environmental stewardship.

Leave a Reply