In the quest for sustainable solutions to production challenges, bacteria emerge as a remarkable ally. These microscopic entities, often viewed through the lens of disease and decay, possess the unique capability to generate valuable materials such as cellulose, silk, and various minerals. The charm of this biological process lies in its sustainability, occurring at ambient temperatures and utilizing water as a medium. However, traditional bacterial production methods face significant limitations, most notably the slow growth rates of these organisms and their inability to generate adequate quantities for commercial usefulness. Thus, the scientific community has been on a relentless pursuit to re-engineer these microorganisms into efficient mini-factories capable of meeting industrial demand.

The Genetic Frontier: A New Approach to Enhanced Production

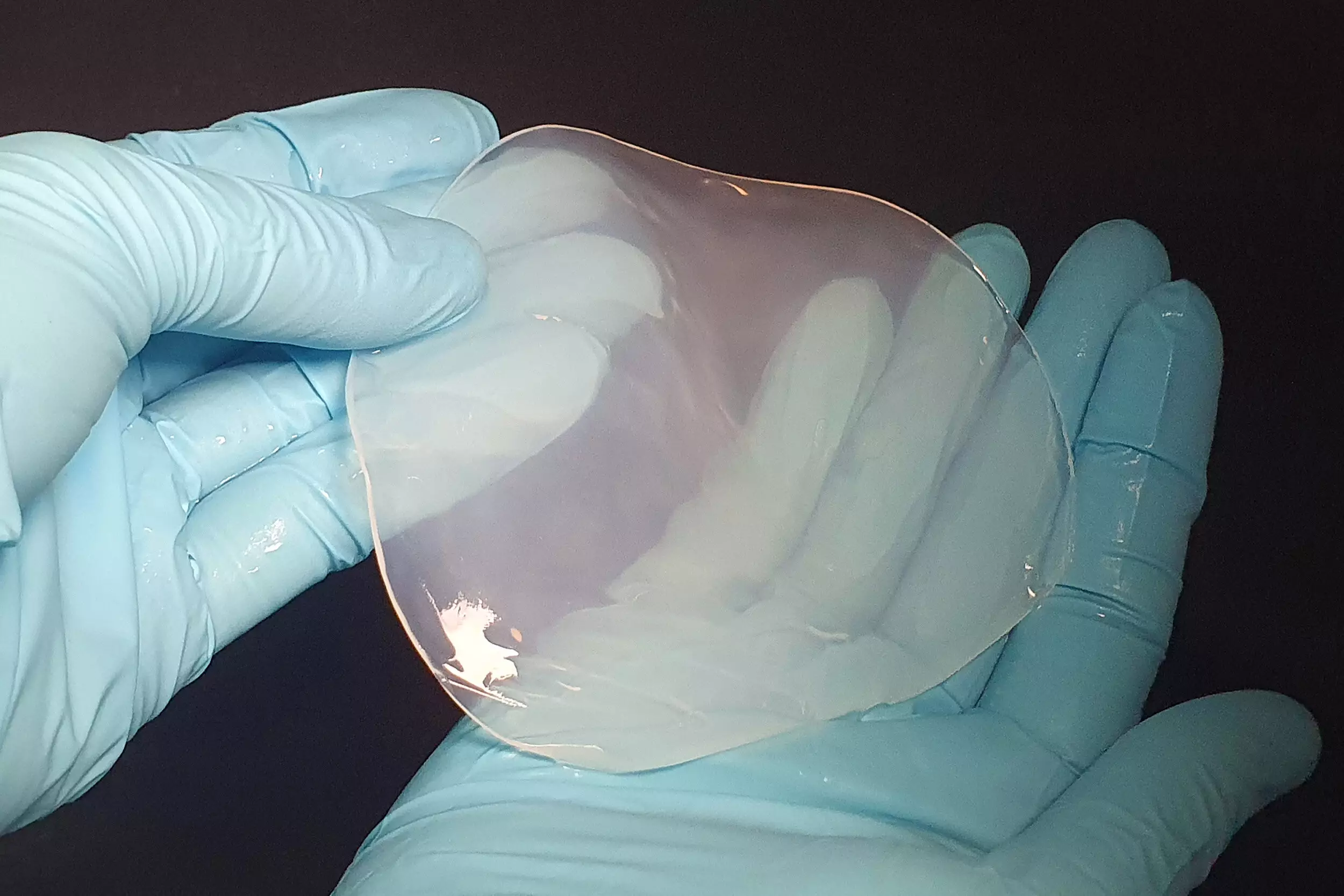

Leading the charge in this innovative frontier is Professor André Studart from ETH Zurich, who is pioneering cutting-edge methodologies to enhance cellulose production in the bacteria Komagataeibacter sucrofermentans. Employing principles of natural selection and evolution, Studart’s team has developed a technique that expedites the generation of thousands of bacterial variants, allowing for rapid identification of strains that yield greater cellulose outputs. The promise of K. sucrofermentans is substantial, as it not only produces high-purity cellulose but also bears immense potential for biomedical applications, including advanced wound healing materials and eco-friendly packaging solutions.

The traditional limitations of K. sucrofermentans in terms of growth rate and cellulose yielding capacity have prompted researchers like doctoral student Julie Laurent to innovate. Under her guidance, a method was devised to increase cellulose production by an impressive 70%. This approach involved inducing mutations in the bacteria’s DNA via UV-C light exposure, subsequently creating conditions that prevented natural DNA repair processes. The result? Bacteria that could produce cellulose in substantially greater quantities, a significant leap towards solving industrial production challenges.

Innovative Techniques: The Evolution of Bacterial Cellulose Production

The methodology adopted by Laurent is groundbreaking. In her experiments, she encapsulates individual bacterial cells within minuscule droplets of nutrient solution, providing the perfect environment for cellulose production. After an incubation period, she employs advanced fluorescence microscopy to pinpoint which cells exhibit elevated cellulose production levels. This intricate process is enhanced further by the utilization of a highly sophisticated sorting system developed by chemist Andrew De Mello. The ability to screen and sort half a million droplets in a matter of minutes underscores the transformative potential of this technology.

Among the strains isolated by Laurent’s team, four new variants stood out, demonstrating cellulose yields that outperformed their wild-type counterparts by 50 to 70%. These variants, capable of creating cellulose mats that are significantly heavier and thicker than their natural relatives, highlight the advances made in microbial optimization. However, the exact mechanisms behind this enhanced production reveal complexities. Genetic analyses indicated that while the genes responsible for cellulose synthesis remained unchanged, alterations in other genes, particularly those associated with a protease (a protein-degrading enzyme), played a crucial role. The hypothesis suggests that the regulation of cellulose production is disrupted, allowing for unrestricted synthesis.

Broadening Horizons: Application Beyond Cellulose

What is particularly exciting about this research is its broad applicability. Originally developed to improve protein and enzyme production, the methods employed by Studart’s team signal a new era of opportunity for bacterial enhancement, specifically for non-protein materials. This innovative strategy not only represents a significant scientific milestone but also opens pathways to develop sustainable production processes for a wide range of bioproducts, potentially paving the way for breakthroughs in biodegradable plastics, textiles, and other materials.

The implications of these advancements reach far beyond laboratory walls. With the researchers applying for patents for their newly mutated bacterial variants, the ambition is clear: to translate these findings into real-world applications. An upcoming collaboration with industrial partners that specialize in bacterial cellulose will allow these innovative strains to be tested under authentic manufacturing conditions, bridging the gap between cutting-edge research and practical application.

Through perseverance and ingenuity, these scientists are not merely tinkering with biological processes; they are redefining the landscape of material production. As global industries face increasing pressure to adopt sustainable practices, the research being conducted at ETH Zurich is a beacon of hope, highlighting that with creativity and determination, bacteria can be transformed from minor players into major contributors in the fight against ecological and material production challenges.

Leave a Reply