The researchers at Aarhus University have discovered an innovative method for recycling polyurethane foam, commonly found in items such as mattresses. This breakthrough is a significant development for the industry aiming to reclaim the original components of the material, thereby improving the quality of products while also reducing costs.

The Environmental Impact of Polyurethane

Polyurethane (PUR) is a versatile plastic material widely used in various applications, including mattresses, refrigeration insulation, footwear, automotive components, and more. While it is considered a wonder material for its diverse uses, polyurethane also poses environmental and climate challenges. The majority of discarded PUR products worldwide end up in landfills or are incinerated, contributing to environmental pollution. Moreover, the primary components of PUR are derived from fossil oil, further exacerbating its environmental impact.

The Global Market for PUR

The global market for polyurethane has seen substantial growth in recent years, with a predicted increase in demand for the material. In 2022, the global PUR market reached almost 26 million tons, and by 2030, it is expected to reach nearly 31.3 million tons, with foam products representing about 60% of the total. Despite the growing demand for PUR, there exists a small but emerging industry focused on chemically breaking down PUR into its original components, polyol, and isocyanate, for reuse in new products.

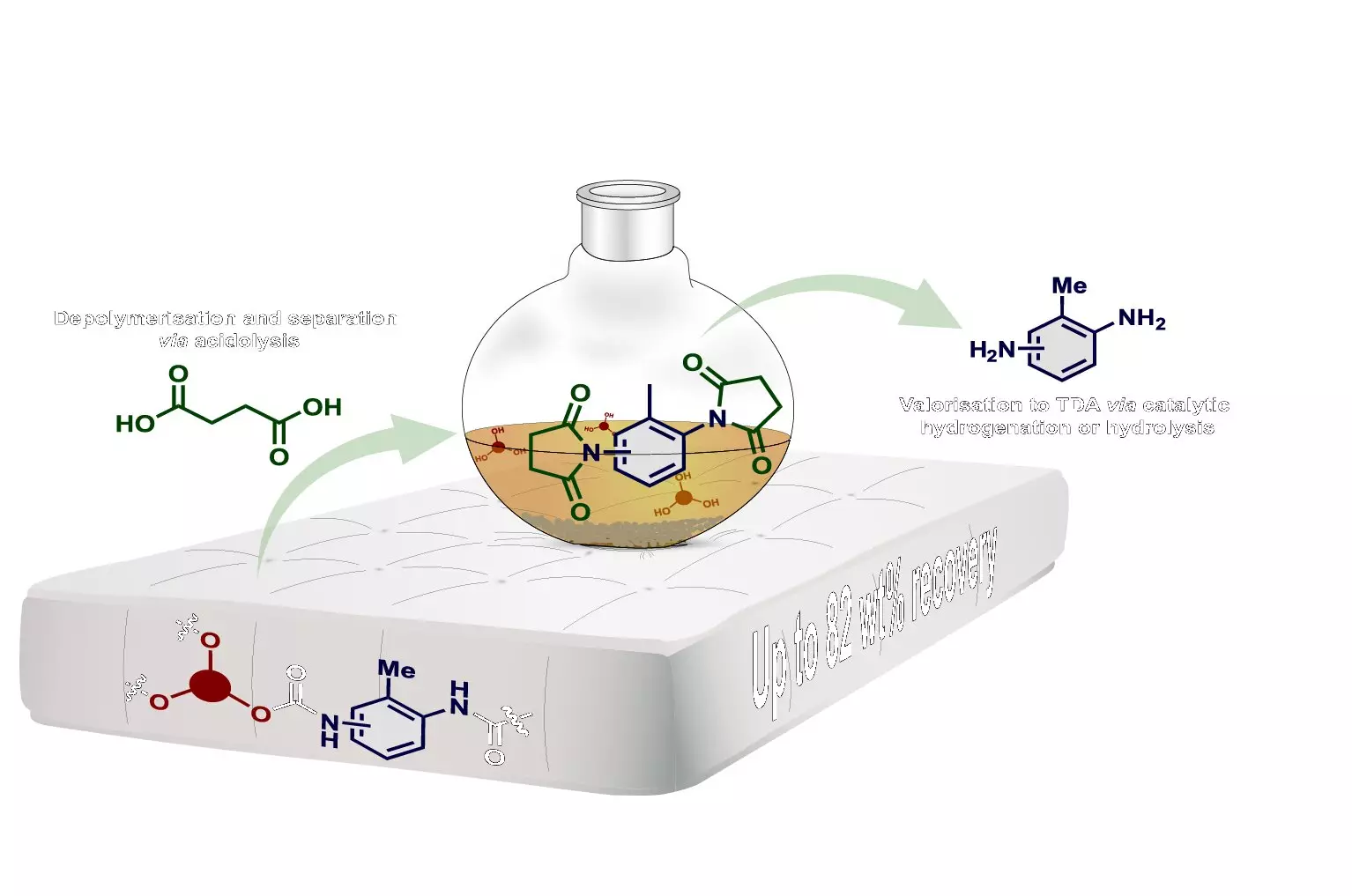

The research team at Aarhus University has devised a novel method for recycling PUR foam that sets them apart from existing practices. While companies typically break down PUR foam using acid (acidolysis), they do not separate the resulting components for recycling. The researchers at AU have successfully developed a process to break down PUR foam and separate it into polyol and isocyanate in a single step. By heating flexible PUR foam to 220°C with succinic acid and using a filtration system to isolate the polyol component, they have achieved a quality comparable to virgin polyol for reuse in new polyurethane products.

Potential for Scalability and Innovation

The researchers’ method offers significant potential for scaling up and revolutionizing the recycling of PUR foam waste in industrial settings. By recovering up to 82% of the original material from flexible PUR foam as separate fractions of diamines and polyols, the researchers have demonstrated the effectiveness of their approach. The ability to transform the solid residue into a diamine for use in isocyanate production further highlights the circular nature of the process.

While the breakthrough in recycling PUR foam is promising, there are still obstacles to overcome before achieving a truly circular economy in polyurethane recycling. Unique formulae used by manufacturers to achieve specific material properties pose challenges in sorting, logistics, and categorizing PUR foam types for recycling. The researchers at AU acknowledge the need for further development to address these issues and fully realize the potential of recycling polyurethane.

The researchers at Aarhus University continue to explore the application of their method on other polyurethane materials, such as regenerated PUR foam and rigid PUR foam. Their efforts to test the technology on different materials and investigate the reuse of dicarboxylic acid demonstrate a commitment to advancing sustainable practices in the polyurethane industry. By creating new products from recycled materials and showcasing the efficacy of their technology, the researchers aim to establish a circular economy for polyurethane.

Leave a Reply