The modern world is increasingly reliant on advanced fluidic technologies, which form the backbone of countless applications across various industries. From pharmaceuticals and healthcare to environmental engineering, the ability to manipulate fluids with precision is essential. Despite significant advancements in the manipulation of solid materials, liquid handling has lagged behind, facing challenges that can lead to inefficiencies and inaccuracies. Recently, researchers from The Polytechnic University of Hong Kong (PolyU) have made a significant stride towards addressing these issues with the development of a new platform known as Connected Polyhedral Frames (CPFs).

Historically, the science of fluid handling has encountered numerous obstacles. In both laboratory and industrial settings, the need for exact capture, transfer, and release of liquids is paramount. Unfortunately, traditional methods are often inadequate. Fluids tend to adhere to surfaces, creating impediments that affect volumetric accuracy and increase the risk of cross-contamination. This challenge is more pronounced in applications where maintaining the integrity of samples is critical, such as in clinical diagnostics or drug formulation.

To further complicate matters, the widespread use of single-use plastics like pipettes and microtubes introduces environmental concerns due to the growing issue of plastic waste. As fluid manipulation becomes more critical across various fields, the limitations of conventional methods necessitate innovative solutions.

Researchers at PolyU, led by Prof. Wang Liqiu, have introduced CPFs as a novel approach to liquid handling. CPFs offer a game-changing capability to switch between liquid capture and release in a reversible, programmable manner, independent of the type of fluid being processed. As detailed in their recent publication in “Nature Chemical Engineering,” this innovative platform operates on the principle of manipulating liquid continuity between connected polyhedral frames.

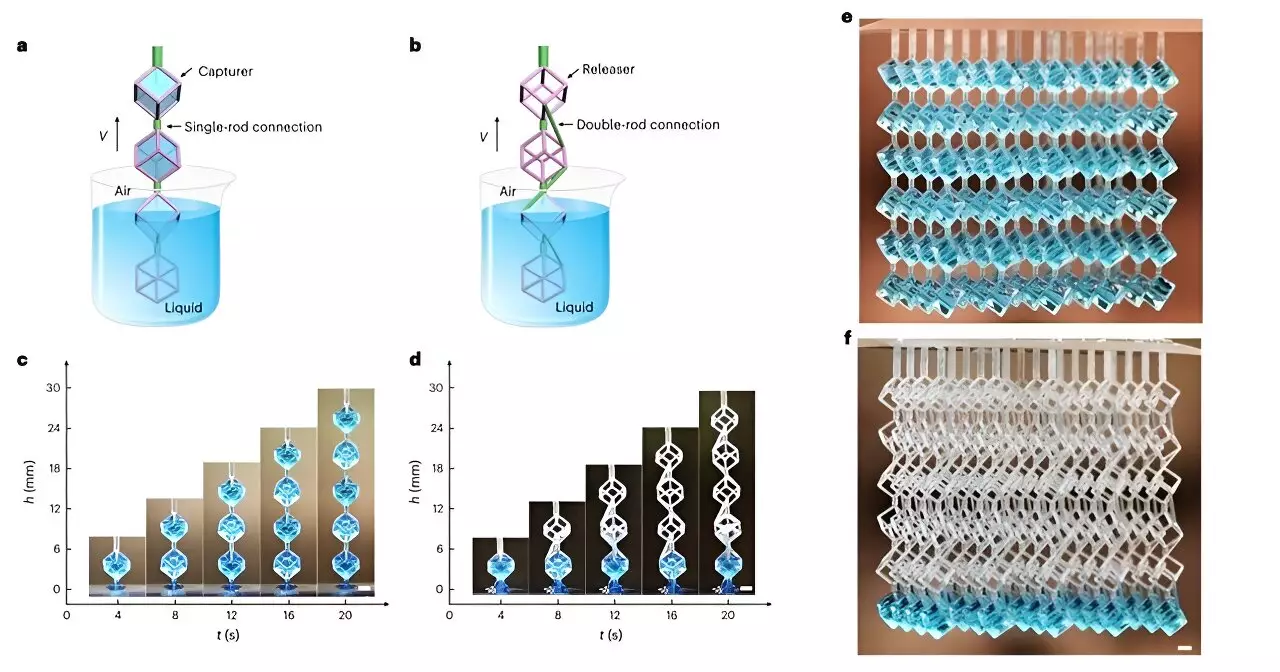

In practical terms, CPFs have a unique architecture: frames arranged over single-rod and double-rod connections. The former type captures and retains liquids, while the latter imbibes and releases them. This dual-functionality is facilitated by the liquid film that forms when the CPFs disengage from a liquid, creating channels that allow for controlled release. By understanding and controlling these dynamic interactions, researchers can manage liquids with unprecedented precision, which opens doors to numerous applications.

The versatility of CPFs is one of their most significant advantages. They can handle a wide array of liquids, from biofluids and hydrogels to polymers and organic solvents. This compatibility allows researchers to integrate diverse materials into their systems for a multitude of applications.

For instance, the team from PolyU successfully demonstrated the application of CPFs in controlled multidrug release. In one study, they created a CPF network for the 3D binary liquid patterning of vitamins, utilizing encapsulation techniques to achieve precise release rates. This level of control is invaluable in fields such as pharmacotherapy, where the timing and dosage of drug release can significantly affect patient outcomes.

Further extending the potential of CPFs, experiments have illustrated their superiority over traditional sampling methods. In tests involving the influenza virus, CPFs performed better than cotton and flocking swabs in detecting low concentrations of the virus, showcasing their enhanced efficiency in sampling.

The implications of CPF technology stretch beyond the biomedical realm. For example, the research team explored CPF applications in environmental engineering. They designed commercial-scale humidifier prototypes with higher water retention capacity and energy efficiency. Furthermore, CPFs can facilitate the large-scale dispersion of liquids, which is beneficial for applications like gas absorption, including processes aimed at carbon capture and storage.

This capacity to generate an ideal CO2 cycle process is crucial for addressing climate change challenges. The ability to utilize CPFs for both carbon capture and CO2 reutilization not only highlights their functional versatility but also emphasizes their potential for significant contributions to sustainability initiatives.

The development of Connected Polyhedral Frames represents a significant leap forward in fluid handling technology. By overcoming longstanding challenges associated with liquids, CPFs position themselves as a pivotal innovation across various scientific and industrial fields. As Prof. Wang and his team continue to explore new applications for CPFs, the potential for breakthroughs in fields ranging from materials science to environmental engineering remains boundless.

The meticulous design and functional versatility of CPFs mark them as a significant advancement, setting a new standard in the meticulous science of fluid manipulation. With the promise of enhancing control and efficiency in liquid handling, CPFs not only serve as a technological marvel but also as a beacon for future research and sustainable practices.

Leave a Reply