The construction industry is constantly evolving, with new technologies and materials being developed to improve efficiency, sustainability, and durability. A recent study led by engineers at the University of Virginia School of Engineering and Applied Science has shed light on the potential benefits of incorporating cellulose nanofibrils into 3D-printed concrete. This innovative plant-based material could revolutionize the way we build structures and pave the way for more resilient and eco-friendly construction practices in the near future.

Cellulose nanofibrils, derived from wood pulp, offer a renewable and low-impact alternative to traditional construction materials. Commonly known as CNF in the industry, this material has shown promise in improving the flow properties and mechanical strength of composites. By enhancing the rheology of 3D-printed concrete, CNF could address the current limitations of printable materials and contribute to the development of more sustainable building practices.

3D-printed concrete has emerged as an exciting trend in the construction industry, offering quick and precise building methods, reduced labor costs, and the potential for intricate designs. However, the existing printable material options are limited, and concerns about sustainability and durability persist. The incorporation of cellulose nanofibrils could address these challenges and enhance the overall performance of 3D-printed structures.

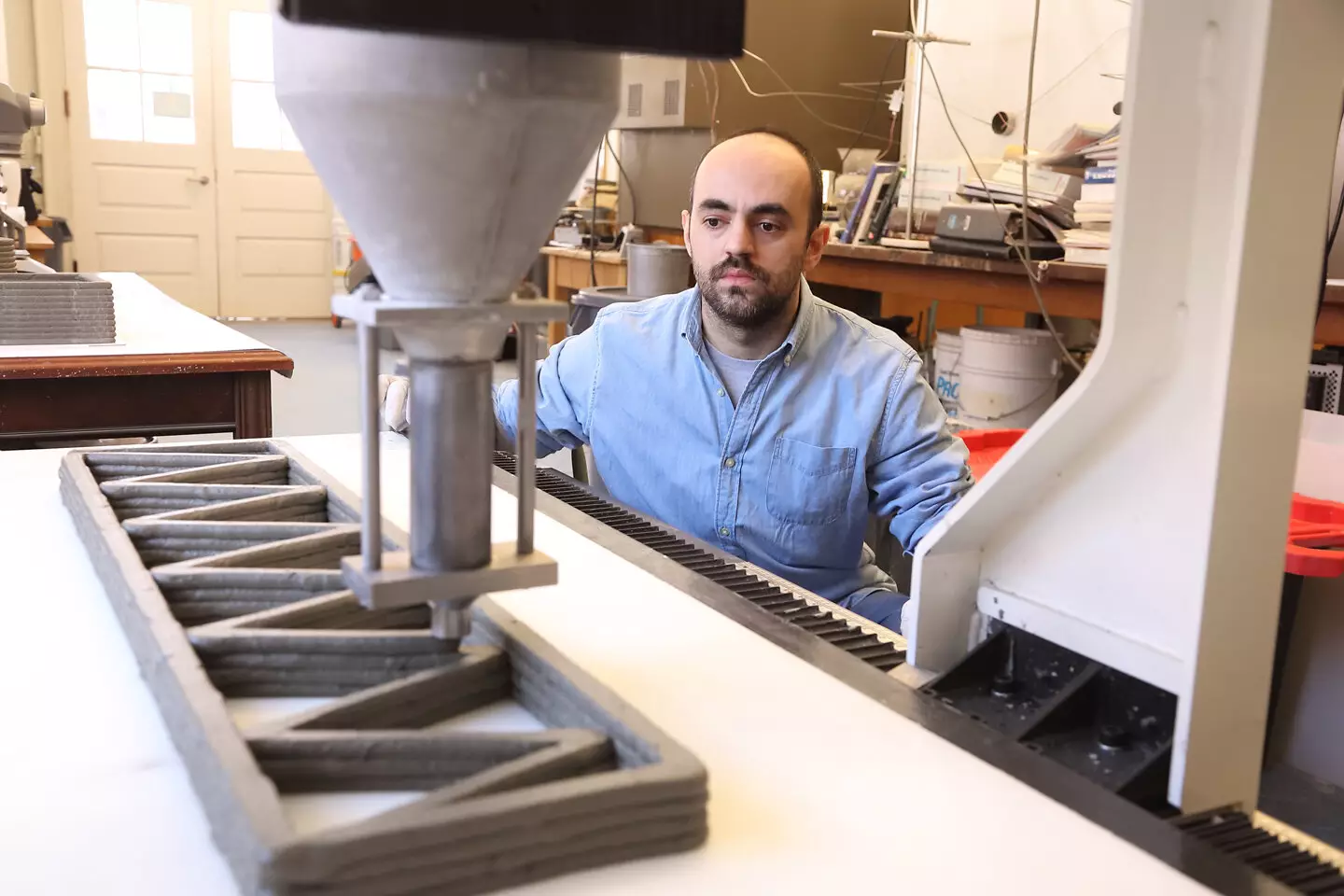

The research team led by Professor Osman E. Ozbulut and Ph.D. alumnus Ugur Kilic conducted a detailed study on the effects of CNF additives in 3D-printed concrete. Their findings, soon to be published in Cement and Concrete Composites, demonstrate that even small amounts of CNF can significantly improve flow performance and enhance material bonding and structural integrity. This breakthrough could pave the way for more resilient and durable 3D-printed components that can withstand various stresses and strains.

As the construction industry continues to embrace new technologies and materials, the integration of cellulose nanofibrils in 3D-printed concrete holds great promise for the future. By harnessing the renewable and sustainable properties of CNF, engineers and architects can create more efficient, cost-effective, and environmentally friendly structures. Further research and development in this area will be crucial to unlocking the full potential of cellulose nanofibrils in construction applications.

The study conducted by the University of Virginia research team represents a significant step forward in the field of construction materials and technologies. By exploring the benefits of cellulose nanofibrils in 3D-printed concrete, the team has opened up new possibilities for improving the sustainability, durability, and performance of future building projects. With continued innovation and collaboration, we can expect to see more advancements in the use of plant-based materials in construction, leading to a more sustainable and resilient built environment.

Leave a Reply