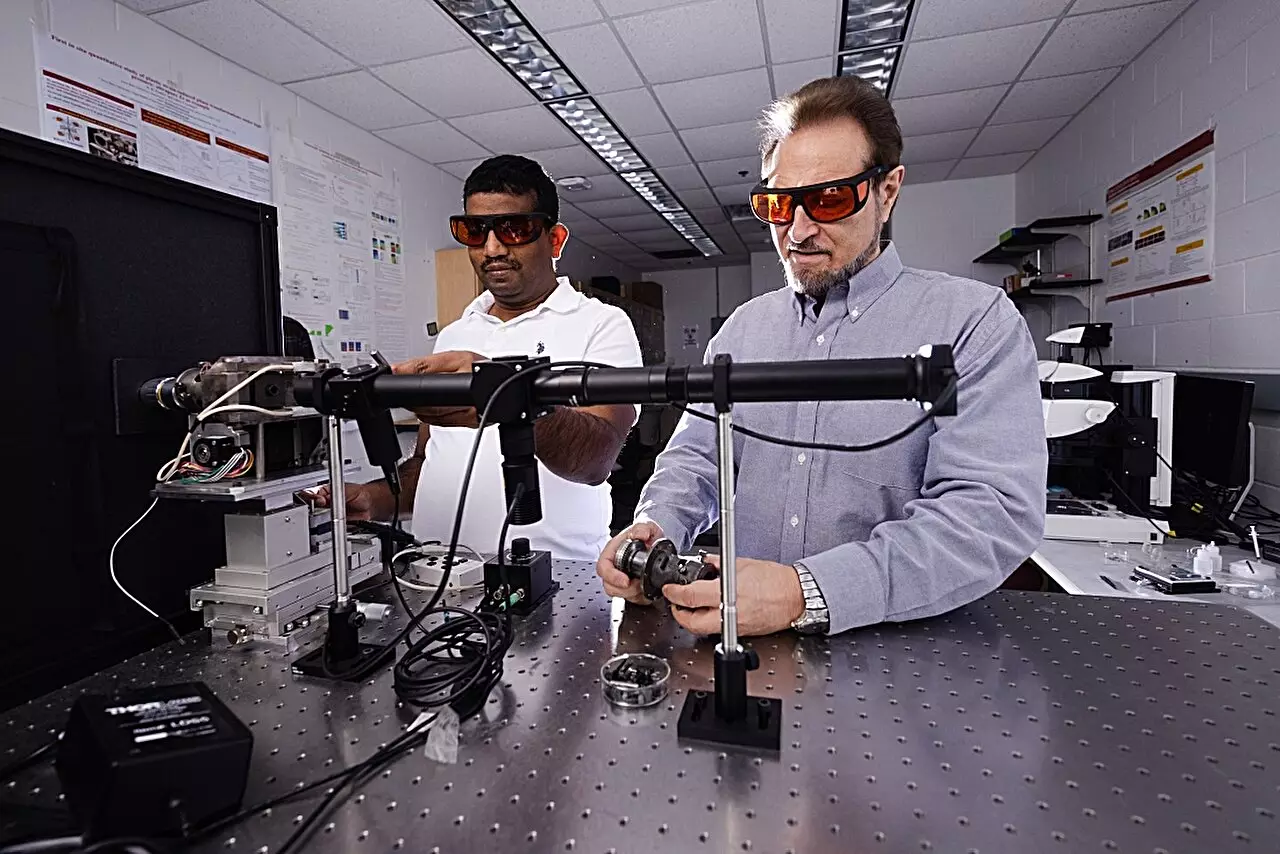

In the realm of materials science, pioneering researchers constantly seek innovative methods to unlock the secrets of materials under extreme conditions. One such researcher, Valery Levitas, has significantly enhanced our understanding of silicon—a cornerstone material in electronics—by applying an advanced technique involving a rotational diamond anvil cell. This tool not only compresses materials but also subjects them to shear deformation, allowing scientists to observe real-time changes in material structures. The ongoing work since Levitas transitioned from Europe to the U.S. in 1999 exemplifies the convergence of multiple scientific disciplines, including advanced mechanics, physics, material science, and applied mathematics.

Recent studies led by Levitas reveal remarkable findings regarding silicon’s behavior under pressure and deformation, particularly those involving plastic, or permanent, deformations. These experiments, stemming from the collaborative efforts of a dedicated research group at Iowa State University and other esteemed institutions, have identified distinct phase transformations under conditions previously overlooked. For instance, the analysis of silicon particles at varying scales (1 millionth of a meter, 30 billionths of a meter, and 100 billionths of a meter) showcased how unique strains can induce phase alterations rarely documented in existing literature.

The team’s findings, notably published in the prestigious journal *Nature Communications*, emphasize that silicon transitions its structure from “Si-I” to “Si-II” at significantly lower pressures than previously believed. Such a transition, which typically occurs at a staggering 16.2 gigapascals, can now be achieved at a mere 0.3 gigapascals under precisely controlled plastic deformation conditions. This is not just an incremental improvement; it represents a staggering reduction in the pressure required for critical phase changes.

Levitas and his collaborators approach the study of material deformation with a unique perspective—shifting the emphasis from merely altering the size of materials to understanding and controlling their microstructural changes. The underlying motivation for such an approach lies in the correlation between the microstructure of a material and its physical properties. Different phases of silicon exhibit varying characteristics, which could potentially be harnessed for a plethora of industrial applications.

The researchers posit that capturing desired nanostructured phases or a mix of phases (referred to as nanocomposites) is now feasible at modest pressures. This finding holds immense promise for industries that have traditionally shied away from methods requiring prohibitively high pressures. By creating desirable silicon phases via plastic deformations, Levitas’s method could revolutionize the way electronic materials are synthesized and utilized.

The implications of these discoveries extend beyond immediate applications in electronics. The research opens avenues for further investigation into how other materials might react under similar plastic shear conditions. Levitas’s work challenges previous assumptions and invites curiosity about the broader impacts of pressure and deformation on materials beyond silicon.

Moreover, industries that seek to innovate must heed these findings, as they demonstrate a viable alternative to the daunting task of working with extremely high pressures. Levitas emphasizes that practicality in industrial applications is paramount. His approach could mean that manufacturers can access properties that were once thought to be limited to high-pressure scenarios, thereby enabling more efficient production processes with enhanced material properties.

Valery Levitas’s research signifies a pivotal moment in material science—a field that thrives on the interplay of theory and experimentation. His expectations of silicon’s response to strains were founded on two decades of reflection and speculation, underlining the importance of scientifically-fueled intuition in research. The innovative techniques employed not only challenge historical perceptions of material behavior under duress but also highlight the latent potential for practical applications that can spring from these new insights. With ongoing advancements, the future of material engineering appears not just promising, but revolutionary.

Leave a Reply