As the demand for high energy density lithium-ion batteries continues to rise, materials like NCM811 have come to the forefront as promising candidates for cathodes. However, a significant challenge arises due to the poly-crystalline structure of these materials. The inherent stresses during the battery’s charge and discharge cycles can induce micro-cracks within the NCM811 cathode, severely impacting the longevity and efficiency of the battery. Understanding the mechanical and chemical evolution of these materials is crucial to mitigating these issues and enhancing battery performance.

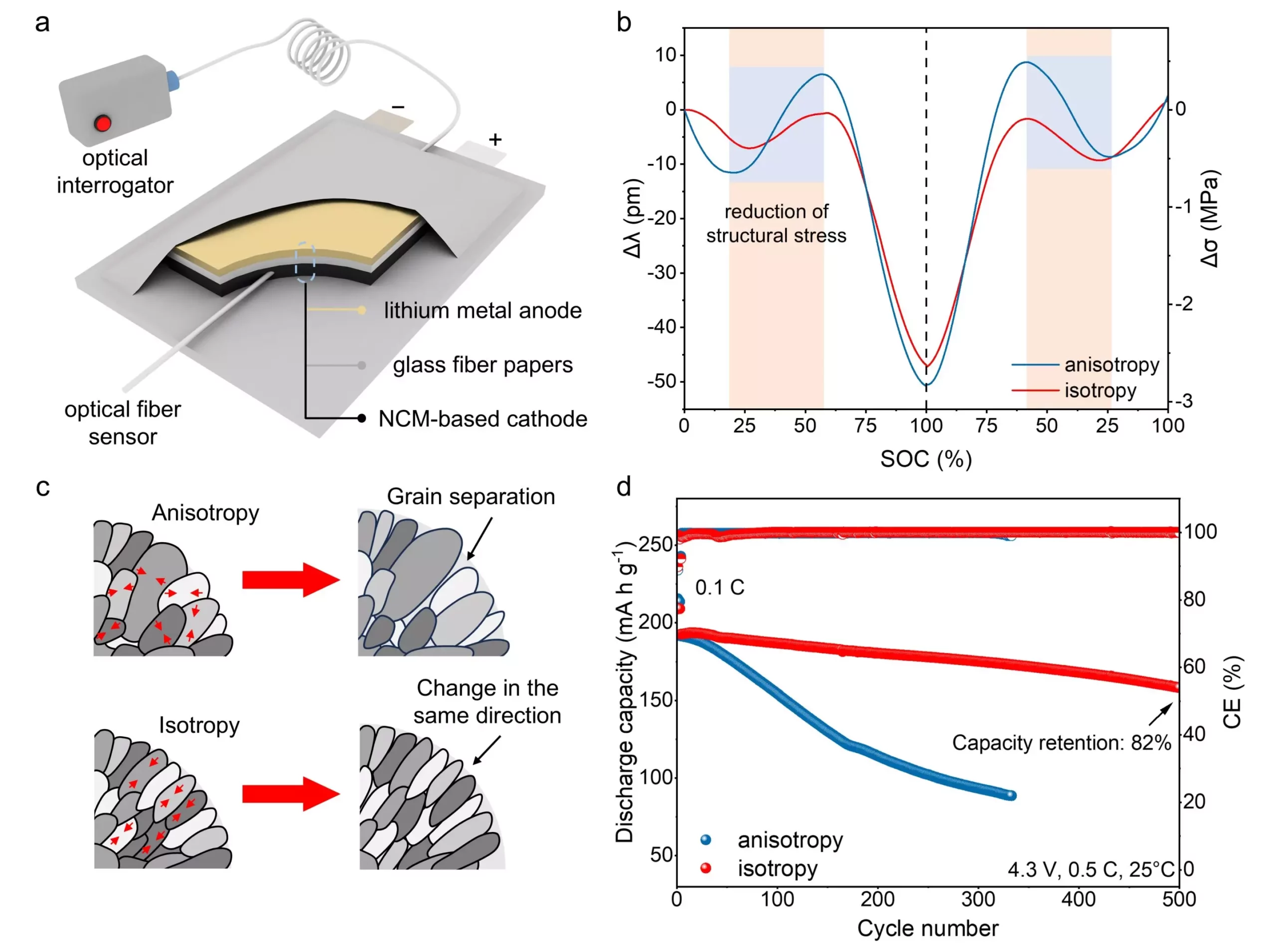

To confront this pressing issue, a research team led by Prof. Yunhui Huang and Prof. Zhen Li has pioneered a revolutionary method of monitoring stress in real-time using an integrated optical fiber system. This innovative approach allows researchers to observe the internal stress dynamics of the NCM811 material at a granular level while the battery operates. The introduction of optical fiber technology serves not only to detect stress variations but also to maintain chemical stability and minimize performance disruption within the battery. This dual functionality is crucial for the practical application of such monitoring techniques in commercial batteries.

The research unveiled that the evolution of stress within the poly-crystalline NCM811 is predominantly influenced by two factors: chemical stress and structural stress. Chemical stress arises from the normal (de)lithiation processes that occur during battery cycling. In contrast, structural stress emerges as a more pressing concern, as it contributes to crack formation and the associated deterioration of battery performance. The findings shed light on the critical relationship between structural integrity and operational lifespan, emphasizing that minimizing structural damage is essential for improving battery functionality.

A deeper investigation into the molecular organization of NCM811 revealed that the stress experienced by the material is intricately linked to the anisotropy of its primary particles and the non-linear fluctuations of the c-axis during lithium insertion and extraction. Thus, the researchers proposed that enhancing the particle arrangement within the cathode could lead to a more stable chemo-mechanical environment. Their trials indicated that poly-crystalline materials with an ordered structure could alleviate structural stress, demonstrating a remarkable capacity retention of 82% after 500 cycles at a 0.5C rate.

Prof. Huang believes that this optical sensing technology holds immense potential for advancing battery monitoring and development. The real-time stress information obtained from optical fibers not only helps decode the complex chemo-mechanical evolution of NCM811 but also aids in guiding the design of more resilient and efficient battery materials. As the field of battery technology continues to evolve, such innovative monitoring solutions will be pivotal in driving the creation of safer, smarter, and more sustainable energy storage systems. The implications of these findings could significantly impact the future landscape of battery technology, ensuring reliable performance in various applications from consumer electronics to electric vehicles.

Leave a Reply