A recent breakthrough from a team of bioengineers at the University of California, Berkeley, is set to redefine the landscape of adhesive technology. Their study, featured in the esteemed journal Science, unveils a new class of environmentally friendly adhesive polymers, highlighting the potential for substantial ecological benefits across a variety of applications. At the heart of their discovery is the introduction of an electrophilic stabilizer designed to halt the depolymerization of fatty acids, primarily α-lipoic acid (αLA), a naturally occurring compound. This innovation not only extends the usability of the polymer but also opens up a myriad of possibilities for sustainable adhesive solutions.

The traditional adhesive market is laden with products that, while effective, often pose significant environmental risks. Many of these adhesives are custom-designed for specific materials such as wood or metal and fail to offer versatility for other applications. Furthermore, the toxic effects of conventional adhesives on flora and fauna present an urgent need for safer alternatives. The Berkeley researchers aimed to address these challenges by creating a polymer adhesive that maintains high performance while being derived from renewable sources. By leveraging α-lipoic acid, which is biodegradable, they have synthesized a range of adhesives that are not only effective for various applications—including medical and non-medical uses—but also ensure minimal harm to the environment.

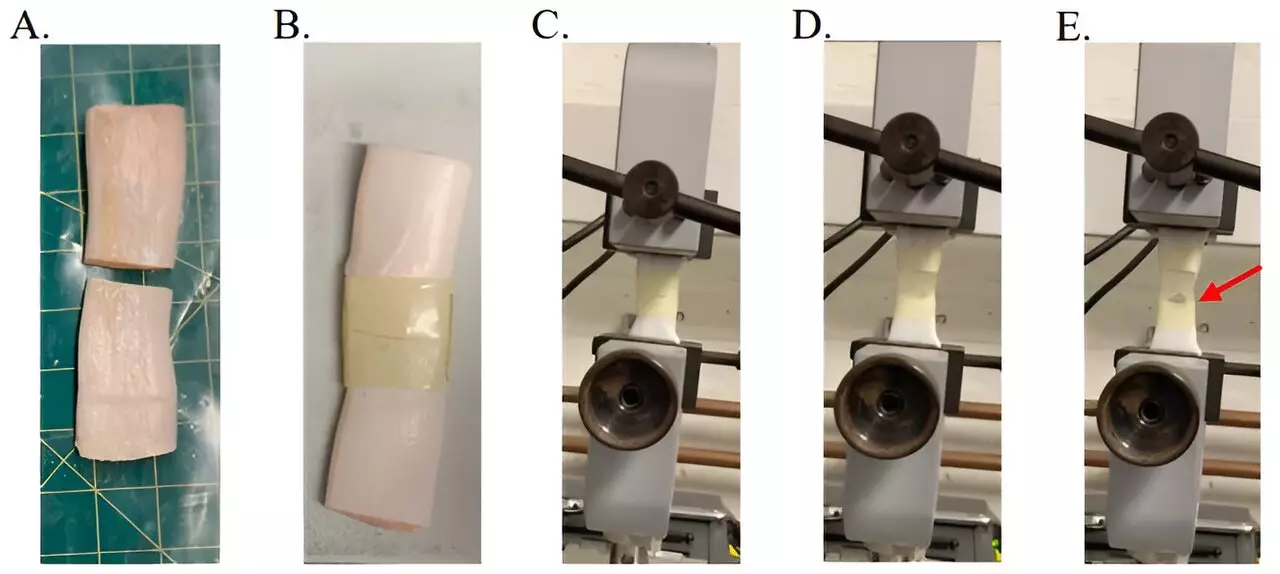

The team conducted extensive testing on their newly developed adhesives, establishing their suitability for applications across an impressive spectrum of materials such as wood, metal, and biological tissues. One notable achievement was the development of a pressure-sensitive adhesive that exhibited a peel strength ten times greater than traditional options. This high-performance characteristic, combined with the adhesive’s functionality in both damp and dry conditions, positions them as superior alternatives to existing products. Importantly, these adhesives do not compromise environmental integrity, promising a sustainable solution for everything from construction to healthcare.

Innovating for a Circular Economy

Furthermore, the researchers have made strides in promoting sustainability through a closed-loop recycling process. This innovative approach allows for the conversion of used adhesives into new adhesives by incorporating an aqueous medium, effectively reducing waste and promoting resource efficiency. The implication of such a process is profound, as it supports a shift towards a circular economy where materials can be perpetually repurposed rather than discarded. Combining this recycling method with the already advantageous properties of these new adhesives marks a significant advancement in both ecological sustainability and resource management.

Future Directions and Implications

As the researchers at UC Berkeley continue to refine their work, the implications of their study extend far beyond the laboratory. The development of aquatic-friendly, self-healing adhesives offers promising avenues for medical applications, enhancing patient care while maintaining ecological responsibility. With the growing demand for sustainable materials in industrial applications, the arrival of these environmentally friendly adhesives could set a precedent in the manufacturing sphere. The potential to revolutionize glue technology while safeguarding our planet underscores the critical importance of innovation in bioengineering. The future looks promising as this groundbreaking research paves the way for new products that harmonize effectiveness with ecological integrity.

Leave a Reply