Polymer electrolyte membrane (PEM) fuel cells are renowned for their efficiency and low environmental impact, making them a strong contender in the search for sustainable energy solutions. However, one of the significant challenges that engineers face is the effective cooling of these fuel cells. As fuel cell stacks generate power, they also produce heat, which, if not properly managed, can lead to severe temperature gradients within the membrane. Such temperature imbalances jeopardize the integrity of the membrane and ultimately affect the fuel cell’s performance and lifespan.

A collaborative research effort between the University of Seville’s Department of Energy Engineering, AICIA, and the Harbin Institute of Technology has revealed crucial insights into the thermal management of PEM fuel cell stacks. The team’s work focused on the cooling capabilities of serpentine-type cooling channels, which are commonly utilized in these fuel cells. By applying numerical heat transfer analyses, the researchers established a new correlation for the Nusselt number, a dimensionless quantity that characterizes convective heat transfer.

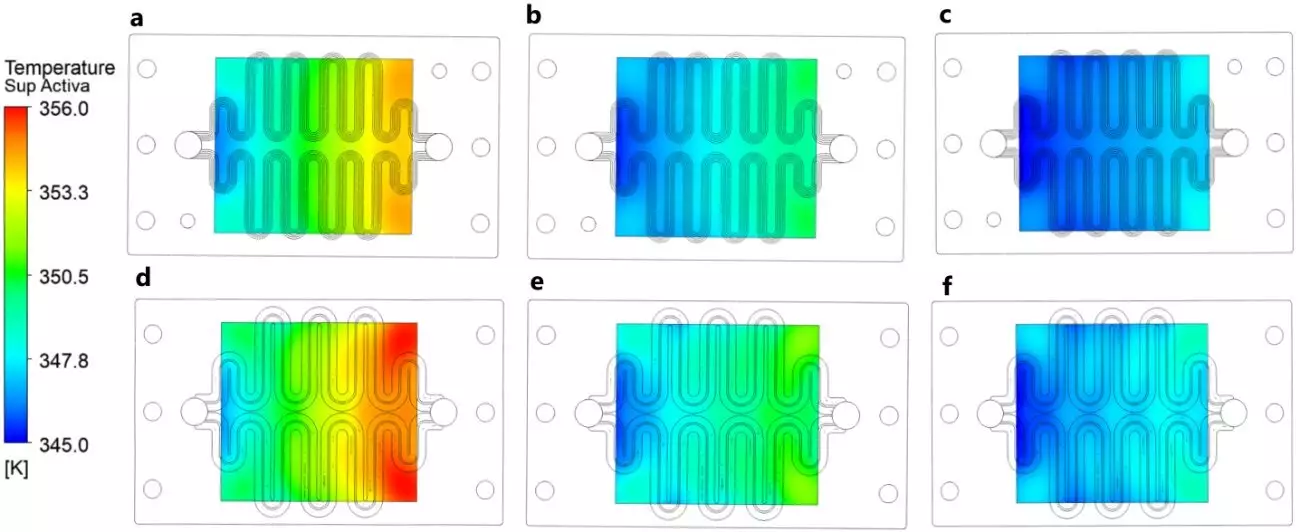

Their extensive computational fluid dynamics (CFD) simulations investigated various parameters, including coolant mass flow rates and bipolar plate thermal conductivity, determining that these factors significantly impact the cooling efficiency of PEMFC stacks. The findings suggest that optimizing these elements could enhance the cooling performance, thereby improving the overall durability of the power generation systems.

The emerging correlations developed from this research not only support the design of more efficient cooling systems but also enable developers to predict potential issues related to heat-induced degradation. By understanding how different cooling strategies affect the heat transfer processes, engineers can refine their designs to prevent excessive temperature excursions, which are known to impair cellular integrity over time.

Cooling is not merely a supplementary function of PEM fuel cells; it is integral to their operational efficiency. Inadequate heat management can lead to increased maintenance costs and reduced reliability. Therefore, reliable correlations in heat transfer mechanisms are vital for the advancement of these technologies.

The introduction of this novel heat transfer correlation opens doors for further improvements in PEM technology. The ability to predict performance under various operating conditions will undoubtedly lead to enhanced designs that maintain optimal temperatures. As the industry moves towards larger-scale applications of fuel cells—such as in transportation and stationary power systems—effective thermal management will become even more critical.

The comprehensive understanding of cooling mechanics presented by this study is a boon for the future of PEM fuel cells. Researchers and engineers are now better equipped to design systems that not only withstand operational stresses but also extend the life and efficiency of these promising energy solutions. As the push for greener technologies continues, innovations in PEM fuel cell cooling systems will play a significant role in the pursuit of a sustainable energy future.

Leave a Reply