The University of Toronto Engineering researchers have come up with a groundbreaking catalyst that efficiently converts captured carbon into valuable products, even in the presence of contaminants that degrade the performance of current catalysts. This discovery marks a significant step towards more economically feasible techniques for carbon capture and storage which can be seamlessly integrated into existing industrial processes.

One of the main obstacles in the field of carbon conversion is the presence of impurities, especially in industrial waste streams. For instance, sulfur oxides like SO2 are known to poison catalysts by binding to the surface, thereby reducing the efficiency of the conversion process. Traditional catalysts are typically designed to operate with a pure CO2 feed, making them vulnerable to impurities like sulfur oxides.

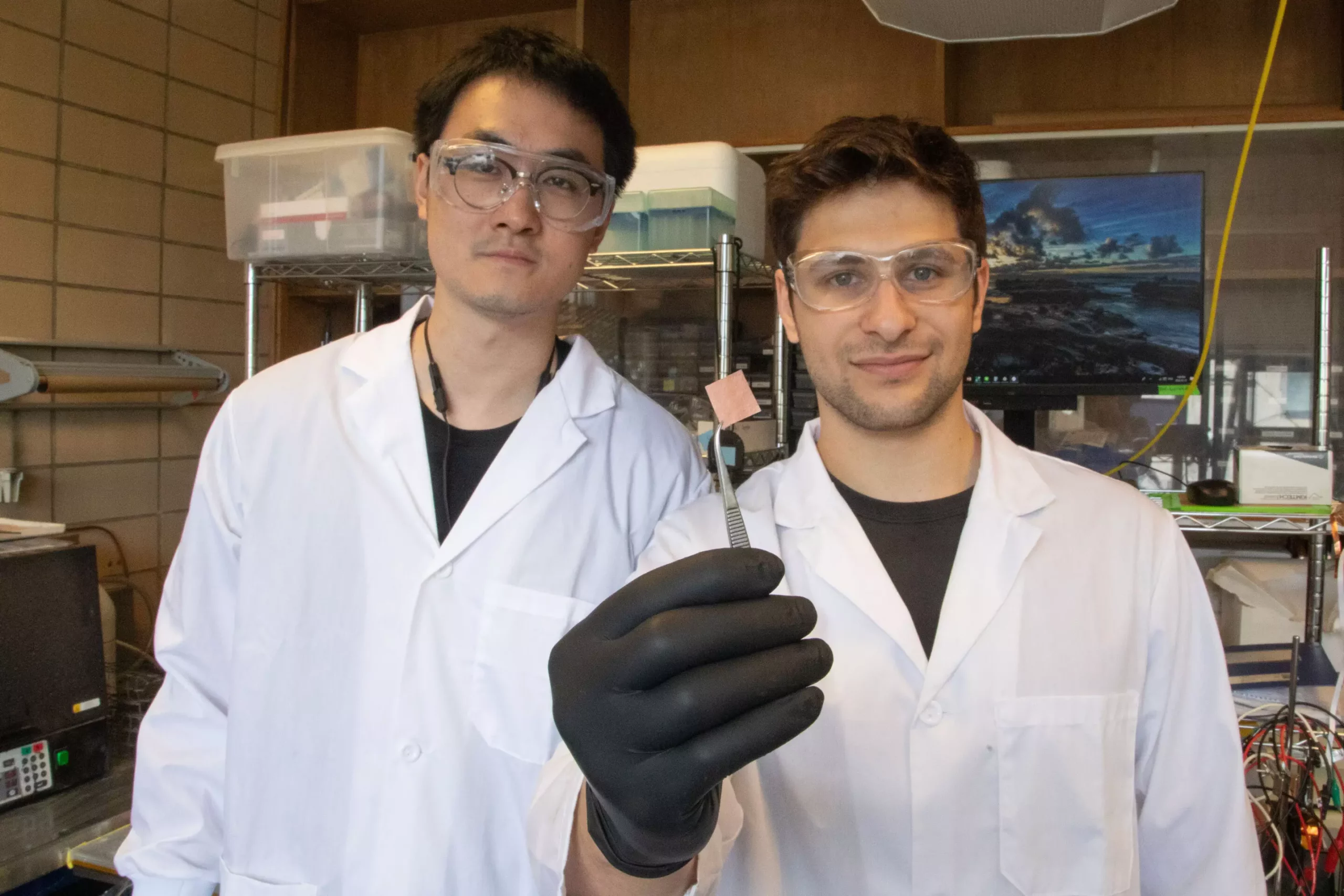

To address this challenge, the research team made two key modifications to a typical copper-based catalyst. Firstly, they added a thin layer of polyteterafluoroethylene, commonly known as Teflon, to the catalyst. This non-stick material alters the chemistry at the catalyst surface, hindering the reactions that lead to SO2 poisoning. Secondly, they incorporated a layer of Nafion, an electrically-conductive polymer, to create a complex and porous material that prevents SO2 from reaching the catalyst surface.

Even when fed with a mixture of CO2 and SO2, with the latter at a concentration of about 400 parts per million, which is standard for industrial waste streams, the newly designed catalyst exhibited remarkable resilience. The team reported a Faraday efficiency of 50%, maintained over a period of 150 hours. While some catalysts may start at a higher efficiency, they quickly deteriorate when exposed to sulfur oxides. In contrast, the new catalyst remained highly efficient even under challenging conditions.

One of the advantages of this innovative approach is that it does not alter the composition of the catalyst itself, making it widely applicable. Teams that have already developed high-performing catalysts can easily implement similar coatings to enhance their resistance to sulfur oxide poisoning. This opens up new possibilities for the widespread adoption of more resilient catalysts in the field of carbon conversion.

While sulfur oxides pose the most significant challenge in waste streams, there are numerous other impurities that need to be addressed. The research team is now focusing on developing solutions to combat the full range of chemical contaminants present in industrial waste streams. The success of the new catalyst in resisting sulfur oxide poisoning is a promising sign of its potential to handle a variety of impurities effectively.

The development of this revolutionary catalyst represents a major advancement in the field of carbon conversion. By creating a catalyst that can withstand the presence of impurities like sulfur oxides, the researchers have opened up new possibilities for more cost-effective and efficient carbon capture and storage techniques. This breakthrough paves the way for a greener future where industries can reduce their carbon footprint without compromising on performance or economic viability.

Leave a Reply