Imagine a world where materials respond dynamically to light, expanding and contracting at the whim of remote control. A groundbreaking development in materials science has emerged from an international collaboration of researchers who have successfully embedded gold nanorods in hydrogels. This innovative combination supports the creation of structures that not only exhibit remarkable responsiveness to light but do so through the sophisticated process of 3D printing. While the field of 3D printing has made significant strides in various applications, this recent advancement promises to unlock new potentials in robotics, soft actuators, and biomedical devices.

At the heart of this innovation lies the integration of gold nanorods within a polymer network that holds water, known as hydrogels. These gold nanorods serve a dual purpose: they enhance the material’s photo-responsive characteristics and facilitate its processing through advanced printing techniques. Joe Tracy, a noted professor in materials science, emphasizes the project’s objective of finding an efficient way to 3D print these intricate structures, embodying both the artistic and functional sides of engineering.

The Science Behind Hydrogels and 3D Printing

Hydrogels are fascinating materials that are prevalent in various domains, ranging from medical applications, such as drug delivery, to everyday items like contact lenses and diapers. The research team did not merely print a hydrogel; instead, they developed a solution containing both gold nanorods and the base ingredients required to realize a hydrogel. This innovative approach required a significant rethink of traditional 3D printing techniques, as the pre-hydrogel solution was characterized by low viscosity—simply printing it on a surface would result in a puddle rather than a stable structure.

To realistically create 3D shapes, the researchers devised a method involving a translucent gelatin slurry. This medium allowed the printer nozzle to accurately deposit the pre-hydrogel solution while remaining penetrable to light, crucial for triggering the chemical reactions necessary for hydrogel formation. Once exposed to light, the solution initiates a cross-linking process that turns it into a solid hydrogel, while subsequently dissolving away the gelatin matrix reveals the meticulously designed 3D structure.

The Remarkable Ability to Respond to Light

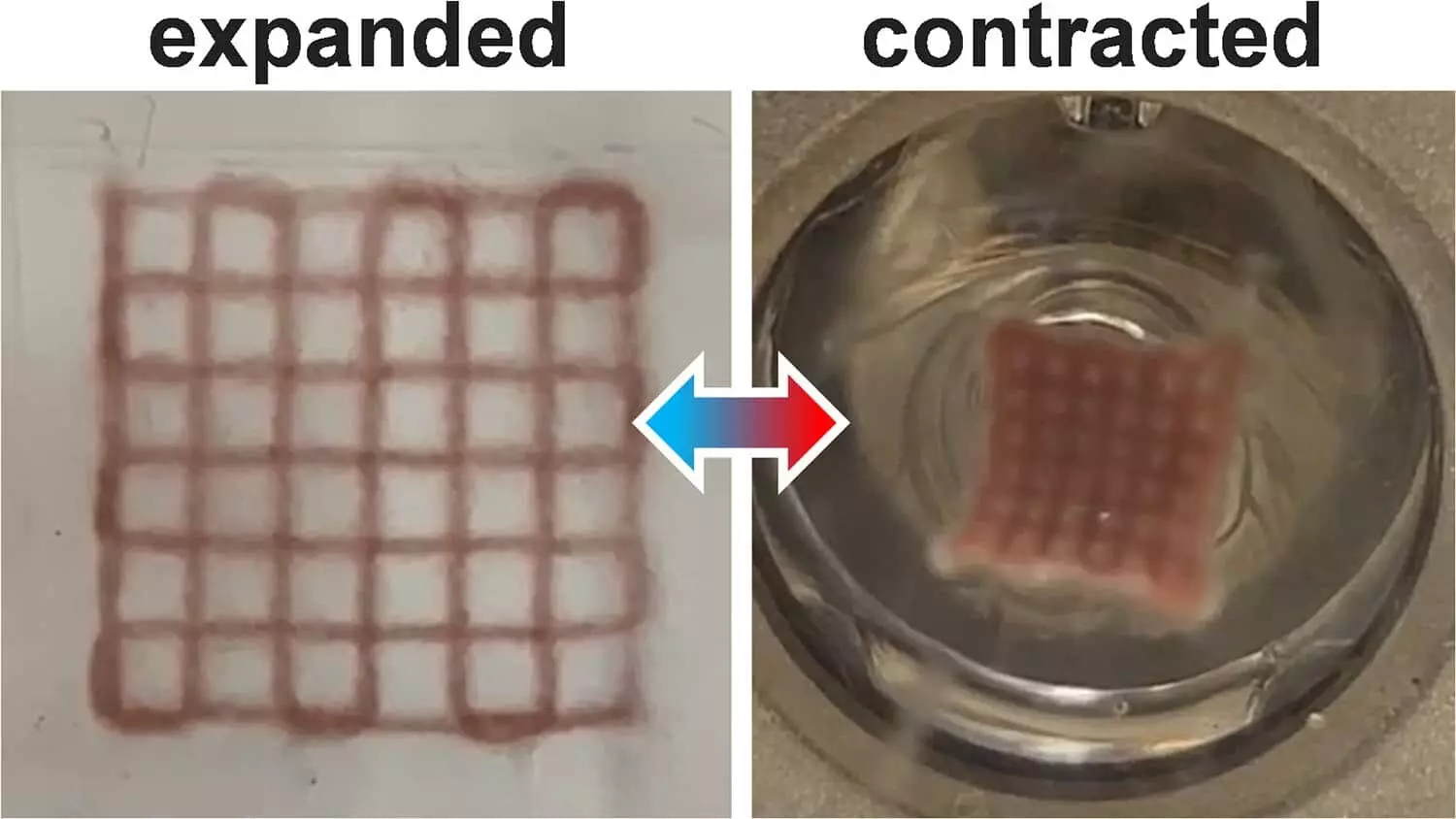

One of the most compelling features of these newly developed hydrogel structures is their ability to respond to light with remarkable efficiency. When illuminated, the integrated gold nanorods absorb the light and convert it into heat. This thermal energy causes the polymers within the hydrogel to contract, effectively expelling water and resulting in a concise, shrunk version of the original structure. Conversely, when the light source is removed, the cooling property of the polymer allows it to reabsorb water, expanding back to its original size.

This light-driven transformation also introduces the capability of remote operation—an invaluable aspect for applications in diverse fields. Melanie Ghelardini, a key contributor to the research, highlights the portability and versatility of this approach; it replaces the need for direct heat application, enabling greater accessibility and functionality in environments where precise control and flexibility of movement are essential.

Unmatched Design Freedom Through 3D Printing

One of the standout advantages of employing 3D printing techniques over traditional mold casting is the comprehensive design freedom it offers. The potential to create custom-tailored structures with exquisite complexity can pave the way for advancements across numerous sectors, including robotics, artificial intelligence, and healthcare. The implications of this method are not merely theoretical; they present a future where actuators can be as intricately designed as the tasks they will perform, whether in robotic arms’ manipulation or the building of responsive biotechnological devices.

The practical applications stemming from this research are poised to revolutionize many facets of technology and human interaction with materials. As researchers continue to refine these techniques and explore their limitations, the outlook is nothing short of thrilling.

The intersection of gold nanorods, hydrogels, and 3D printing is shaping a transformative era in materials science. It encourages us to reimagine the capabilities of everyday products and highlights the exciting possibilities that lay ahead for responsive materials in an increasingly digital, automated world.

Leave a Reply