With energy demands soaring globally, the renewable sector is embarking on a new frontier: the development of high-temperature superconducting (HTS) wires. These wires are poised to dramatically alter how we generate, transmit, and utilize energy. Capable of conducting electricity without resistance at surprisingly high temperatures when compared to their traditional counterparts, HTS wires represent not only a leap in our technological capabilities but also a bridge to potentially achieving sustainable energy sources like commercial nuclear fusion. However, before these wires can realize their full potential in large-scale applications, they must achieve a cost-performance balance that rivals that of conventional copper wiring widely available in hardware stores.

Breakthroughs from the University at Buffalo

Recent advancements from a multidisciplinary research team at the University at Buffalo mark a significant step towards making HTS technology commercially viable. Their study, published in *Nature Communications*, reported the creation of the highest-performing HTS wire segment to date. Utilizing rare-earth barium copper oxide (REBCO), the wires demonstrated peak performance levels in critical current density and pinning force — metrics crucial for their application in magnetic fields and temperature ranges spanning from 5 Kelvin to 77 Kelvin. While it’s essential to note that these temperatures sit well below ambient conditions, they are nevertheless higher than the absolute zero required by traditional superconductors.

Research leader Amit Goyal, a distinguished professor from the SUNY Empire Innovation Program, underscored the importance of optimizing production methods to enhance the price-performance ratio. This improvement is essential if we are to realize the large-scale applications envisioned for superconductors, including innovative energy generation and transmission techniques.

Applications in Diverse Fields

The implications of HTS wire technology cut across multiple sectors. From energizing offshore wind generators and crafting grid-scale superconducting magnetic energy-storage systems to revolutionizing transformers and electrical motors, the range of possibilities is striking. One of the most compelling applications lies in the realm of nuclear fusion, which could potentially yield limitless clean energy. In fact, in just a few years, around 20 start-ups have emerged globally focusing on nuclear fusion technologies, spurred by massive investments aimed specifically at improving HTS wire technologies.

Beyond energy generation, HTS wires are set to redefine medical imaging technologies such as magnetic resonance imaging (MRI) and nuclear magnetic resonance (NMR), crucial for drug discovery and various branches of physics. Furthermore, advancements in defense technologies such as all-electric ships and airplanes are also on the horizon, highlighting the overarching importance of HTS wire innovation in both civilian and military applications.

Technological Innovations Driving HTS Development

Currently, many companies around the world relying on cutting-edge fabrication technologies trace their roots back to innovations developed by Goyal and his team. Techniques such as Rolling Assisted Biaxially Textured Substrates (RABiTS) and Ion-Beam Assisted Deposition (IBAD) of magnesium oxide have been pivotal in ensuring the production of kilometer-long, high-performance HTS wires. More significantly, the emergence of nanocolumnar defects through a combined phase-separation and strain-driven self-assembly processes has proven essential in facilitating higher current-carrying capabilities.

The recent research reveals remarkable accomplishments in generating ultra-high-performance REBCO-based superconducting wire segments. Notably, at 4.2 Kelvin, the wires managed to transport a staggering 190 million amps per square centimeter without any external magnetic field—the “self-field.” Even with a challenging magnetic field of 7 Tesla, they sustained a current density of 90 million amps per square centimeter. This level of performance is unprecedented, suggesting that we are nearing a tipping point for practical applications of high-temperature superconductors.

The Science Behind the Success

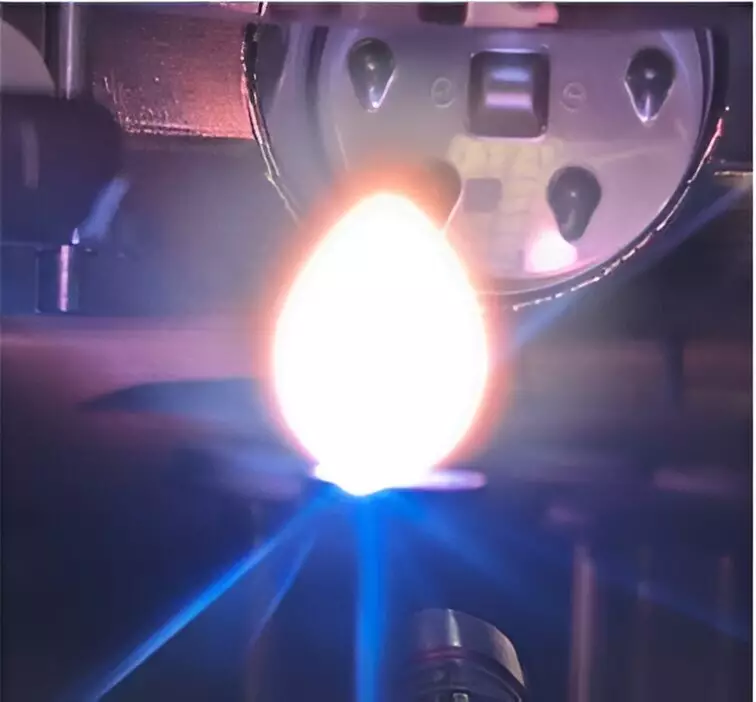

The success of this latest generation of HTS wires can be attributed to several factors, including advancements in pinning effects through rare-earth doping and oxygen-point defects, allied with the creation of insulating barium zirconate nanocolumns. These nanostructures play a crucial role in immobilizing magnetic vortices, which in turn enable higher supercurrents to flow. Goyal’s team meticulously employed advanced pulsed laser deposition techniques to fine-tune the growth of the HTS films, ensuring optimum performance.

In addition to surface enhancements, advanced atomic-resolution microscopy facilitated by the Canadian Centre for Electron Microscopy enables an analysis of nanocolumnar and atomic-scale defects that contribute to the wires’ superconducting properties. Such detailed scrutiny allows researchers to iterate and refine HTS wire design continuously.

The momentum generated by these breakthroughs is formidable, heralding a future where high-temperature superconducting wires facilitate a leap towards a sustainable and energy-efficient world. The landscape of energy generation and consumption stands at the cusp of transformation, fueled by relentless innovation and a commitment to harness the inherent abilities of superconductivity for a greener tomorrow.

Leave a Reply