In a groundbreaking advancement in the field of materials manufacturing, researchers at the University of California San Diego have unveiled a novel 3D printing technique that leverages the simplicity of polymer ink mixed with salt water. This method, as detailed in their recent publication in *Nature Communications*, is poised to redefine how structures are produced, emphasizing sustainability and environmental health.

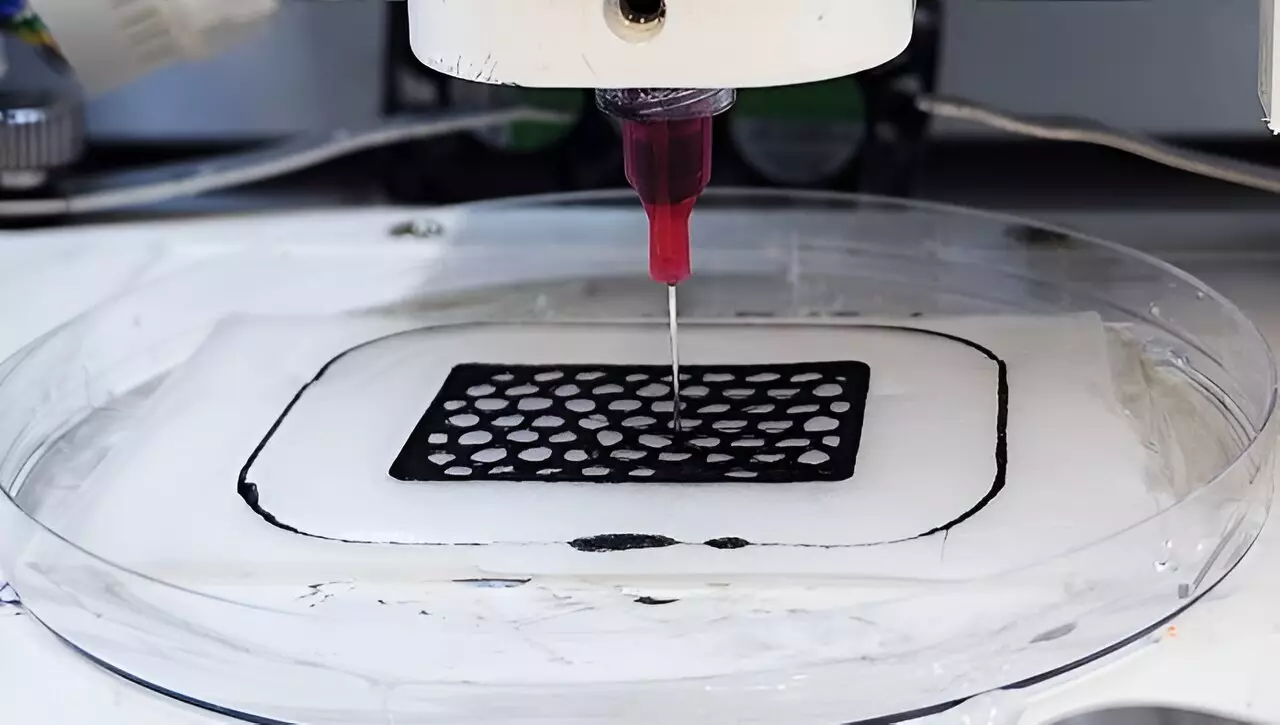

At the heart of this innovative method is a liquid polymer known as poly(N-isopropylacrylamide), or PNIPAM. When extruded from a needle into a calcium chloride salt solution, the polymer undergoes an instantaneous solidification process. This remarkable transformation occurs due to the salting-out effect, where salt ions preferentially attract water molecules, leading to the aggregation of hydrophobic polymer chains. In simple terms, the water is drawn out of the PNIPAM solution, forcing it to solidify upon interacting with the salt water. Unlike traditional polymer solidification processes that often rely on harsh chemicals, extreme heat, and complex machinery, this technique operates effectively under ambient conditions, marking a pivotal shift towards more eco-friendly practices.

One of the standout features of this new printing technique is its environmental advantage. Existing solidification methods are typically energy-intensive and can be harmful to ecosystems due to the chemicals involved. In stark contrast, the UC San Diego researchers have crafted a process that minimizes ecological repercussions, using only harmless components. Furthermore, the solid structures created through this method are not permanent; they can be easily dissolved back into their liquid form in fresh water. This characteristic not only allows for the reuse of the PNIPAM ink for subsequent prints but also presents an innovative approach to recycling materials within the manufacturing process.

The researchers have successfully demonstrated the versatility of this approach by incorporating various materials into their PNIPAM ink. A notable application involved creating an electrical circuit by mixing PNIPAM with carbon nanotubes, which was capable of powering a light bulb. This example illustrates the significant potential for producing water-soluble and recyclable electronic components. The ability to dissolve and repurpose these circuits aligns with growing priorities in sustainable technology, offering a glimpse into a future where electronic waste can be significantly reduced.

The work of Professor Jinhye Bae and her team signifies an important step toward more sustainable polymer manufacturing technologies. By offering a simple, reproducible, and eco-friendly method, the researchers are expanding the possibilities for how materials can be engineered and utilized. As industries increasingly seek to balance innovation with environmental stewardship, this technique may not only enhance manufacturing efficacy but also lead to a substantial reduction in ecological footprints associated with conventional polymer production methods. The potential ramifications of this advancement could be profound, ushering in a new era of responsible material consumption and production.

Leave a Reply