In the realm of modern technology, piezoelectric materials serve as the backbone for essential applications, ranging from sonar systems to ultrasound imaging devices. These materials derive their functionality from a phenomenon known as ‘spontaneous polarization.’ This characteristic results from the arrangement of dipoles—pairing positively and negatively charged ions within the material. Ideally, for piezoelectric materials to perform optimally, these dipoles must be aligned, a process termed ‘poling’. Traditional methods of restoring alignment involve exceedingly high temperatures, which necessitate disassembling devices and can ultimately compromise the integrity of the components. This not only poses a significant operational challenge but also translates to higher economic costs due to material wastage.

Recent advancements reported in “Electrical De-poling and Re-poling of Relaxor-PbTiO3 Piezoelectric Single Crystals without Heat Treatment,” published in Nature Communications, have introduced an innovative technique that allows for the restoration of piezoelectric properties at room temperature. This groundbreaking approach significantly reduces the hassle often associated with repairing ultrasound technologies. The implications of this study are profound; not only does it simplify maintenance, but it also opens new avenues for developing advanced ultrasound applications that were previously constrained by material limitations.

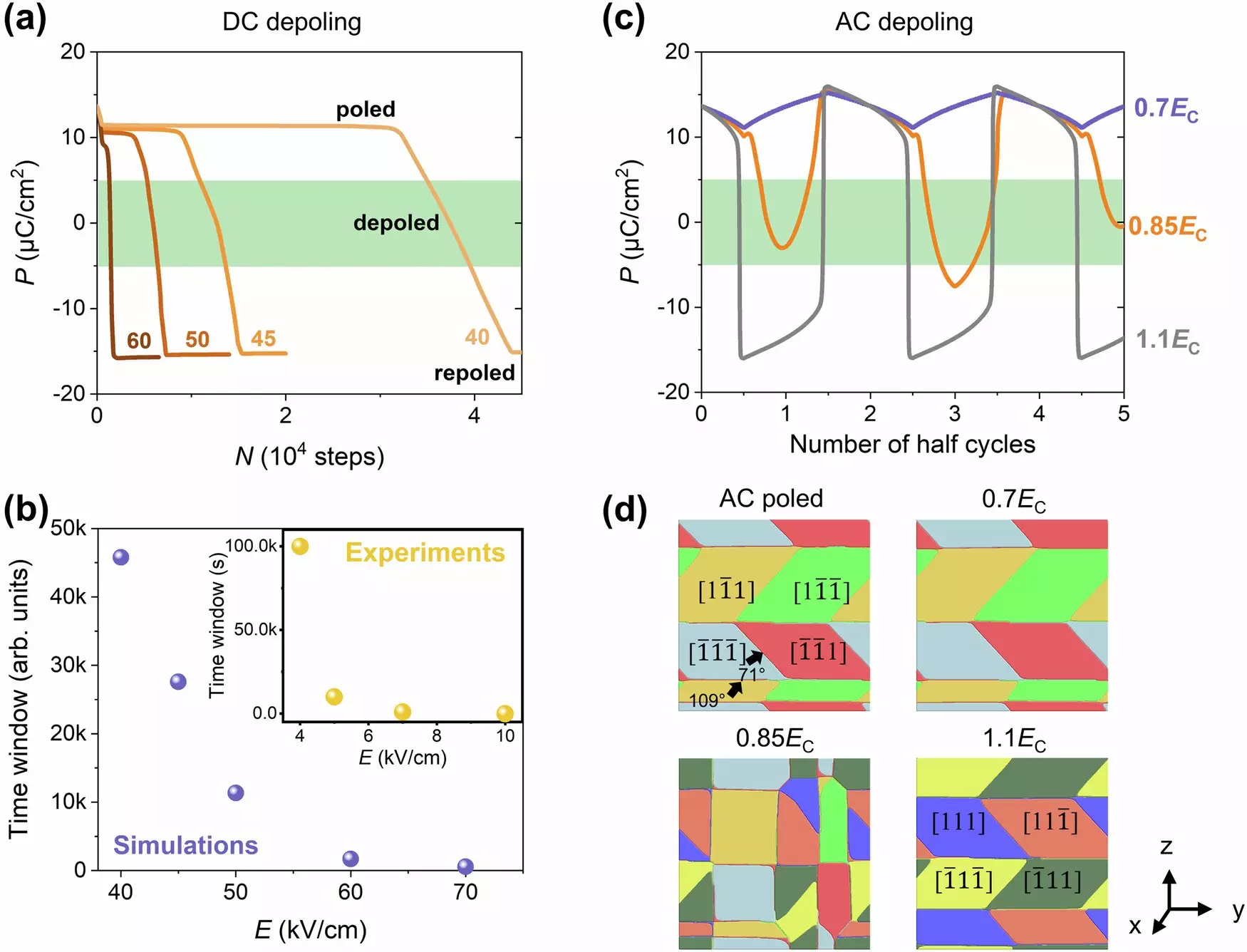

The previously established paradigm dictated that the only viable techniques for aligning dipoles involved either a direct current (DC) or an alternating current (AC) electric field. The challenge lay in the fact that while DC fields efficiently align dipoles, they prove ineffective for depoling the material. Conversely, AC fields, traditionally viewed as a method for inducing oscillation, can now be employed to restore alignment even at ambient conditions. This realization signifies a profound shift in the methodology regarding piezoelectric material management.

The ability to manipulate piezoelectric materials at room temperature presents various implications for manufacturing practices. Researcher Xiaoning Jiang, a lead author of the study and a professor at North Carolina State University, notes that previously, the constraints imposed by high-temperature processes limited innovation in ultrasound device design. Device manufacturers had to select materials carefully to avoid compromising polarity, an aspect which stymied performance optimization.

Now, with the capability to polarize materials post-assembly, engineers can explore novel combinations of components and manufacturing processes that were once off-limits due to potential depoling risks. With this newfound flexibility, manufacturers can tailor devices specifically to achieve enhanced functionality, thereby improving the effectiveness of ultrasound technologies in both medical settings and industrial applications.

One of the significant advantages of this methodology is its potential to promote sustainability within the industry. Piezoelectric materials, particularly those used in high-performance settings, tend to be expensive. Historically, once these materials lost their polarization and required high-heat treatments, it often resulted in the disposal of otherwise reusable components. Jiang emphasizes the financial and environmental benefits tied to this new technique: retaining and reusing costly materials directly contributes to a more sustainable manufacturing ecosystem.

Moreover, the opportunity to repair existing devices without extensive downtime or expenditure only serves to further enhance economic efficiency. Industries relying on ultrasound technologies can benefit from reduced maintenance costs and enhanced longevity of their devices, ultimately improving operational effectiveness.

The findings emerging from the study not only illuminate the path ahead for piezoelectric materials but create a robust foundation for future advancements in ultrasound technologies. As this innovative technique garners attention from various sectors, the ripple effects could lead to significant improvements across a multitude of domains, enriching both medical diagnostics and industrial inspections.

By shifting paradigms in how we approach piezoelectric material restoration, researchers like Jiang and their teams are not just repairing devices but are architecting the future of how we understand and utilize the inherent properties of these remarkable materials. The era of high-pressure, high-temperature textural demands may soon become a relic of the past, facilitating a new landscape filled with possibilities for innovation and growth. Such achievements transcend mere technical advancements; they signify a philosophical shift in our approach to materials science and engineering, forging paths toward a more efficient, sustainable future.

Leave a Reply