Polymers such as Nylon, Teflon, and Kevlar have undeniably reshaped the modern world. These large-molecule compounds form the basis of countless applications that permeate our everyday lives, from cookware to advanced technology utilized in various industries. The constant pursuit of new polymers that can address emerging challenges is a daunting task. However, groundbreaking strides in materials science are being fueled by innovative technologies, particularly artificial intelligence (AI). Researchers at Georgia Tech, under the guidance of Professor Rampi Ramprasad, are at the forefront, employing AI to expedite the discovery and development of new materials that could significantly alter various sectors.

Advancements through Artificial Intelligence

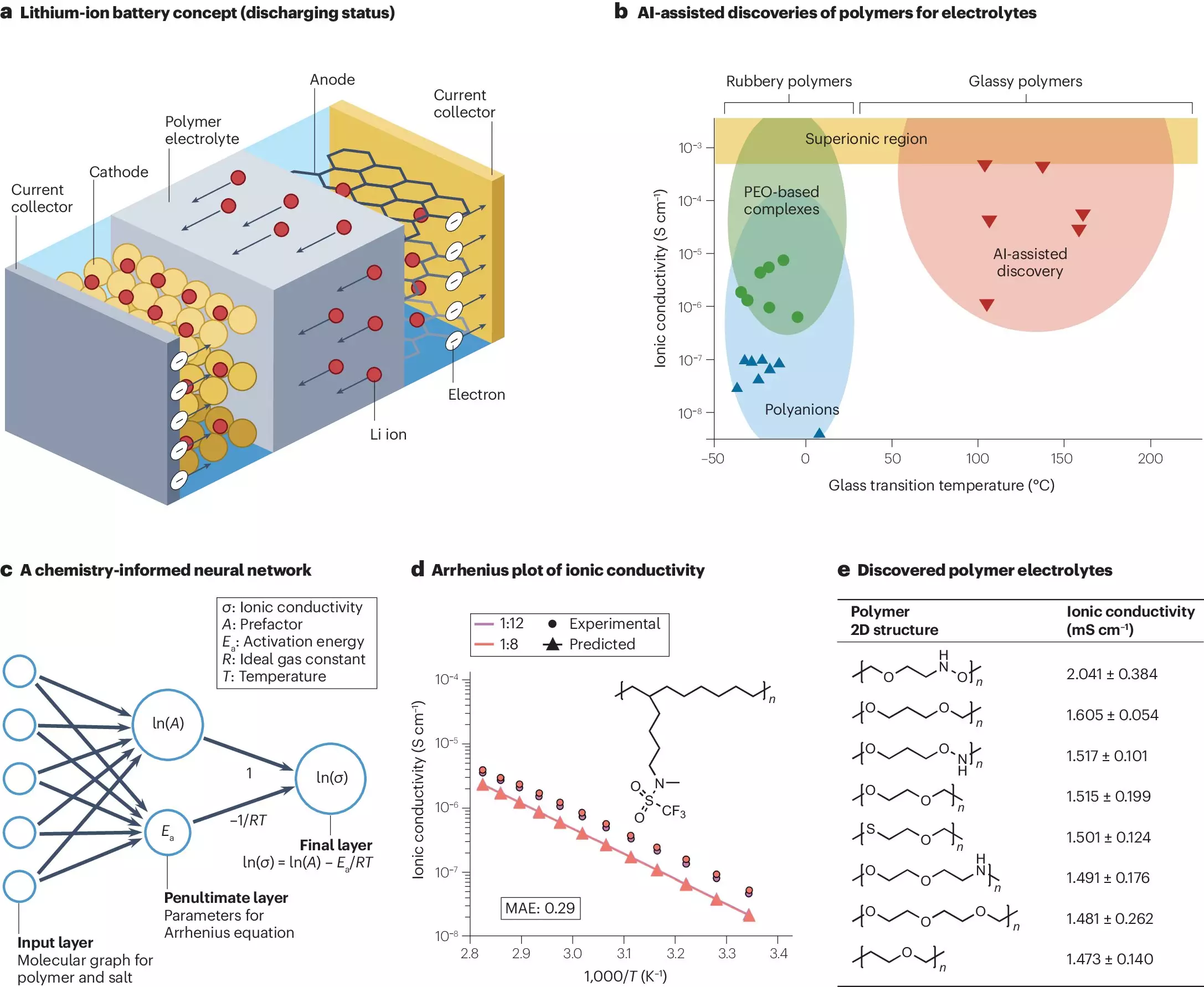

The recent publications in prestigious journals highlight the potential of AI to revolutionize materials research. One of the noteworthy papers, published in *Nature Reviews Materials*, outlines the vast applications of AI in polymer design, particularly in energy storage, filtration systems, and sustainable materials. Meanwhile, another paper in *Nature Communications* details how AI algorithms can identify new subclasses of polymers specifically suited for electrostatic energy storage applications.

This unprecedented merging of AI and polymer informatics allows researchers to predict polymer characteristics and formulations swiftly. The innovative approach begins with identifying specific properties desired for the application at hand. From there, machine learning models analyze existing material-property databases, tailoring predictions towards fulfilling those pre-defined criteria. This allows scientists to generate theoretical polymers, rigorously evaluate their suitability, and eventually synthesize and test the best candidates in the lab.

While AI brings remarkable opportunities for speeding up polymer discovery, it does not come without its set of challenges. The reliability of AI predictions heavily relies on the quality and breadth of input data. It is essential to have comprehensive and diverse data sets to facilitate accurate machine learning. Besides this, crafting algorithms that can not only suggest hypothetical materials, but also ensure that these can be realistically synthesized remains a significant hurdle in the journey from computer-generated designs to laboratory results.

The collaborative nature of this research is also vital to success. Ramprasad’s group works closely with scientists and engineers from other institutions to address these challenges and bring new materials to life. These collaborations facilitate a broader approach to finding solutions, leveraging diverse expertise that helps confirm theoretical findings and push boundaries within the field.

One significant achievement in this realm is the development of new polymer materials designed for capacitors that effectively store electrostatic energy. As we enter a new era of electric vehicles and renewable energy solutions, the demand for high-performing capacitor materials has surged. Historically, existing capacitor polymers either excelled in energy density or thermal stability—only recently has it become feasible to produce polymers that possess both qualities.

With the help of AI, researchers have identified polymers such as polynorbornene and polyimide that meet these dual requirements. This endeavor represents a triumph not only in material science but also showcases the transformative capacity of AI in practical applications, particularly within automotive and aerospace industries, where the need for efficient and stable energy storage mechanisms is paramount.

The wide-ranging implications of AI-assisted materials development are underscored by contributions from industrial stakeholders, including researchers from prestigious companies such as Toyota and General Electric. Their involvement highlights a significant trend: the increasing collaboration between academic research and industrial applications to speed up the transition of novel materials from laboratory concept to production.

Recognizing the importance of bridging research with industry needs, Ramprasad co-founded Matmerize Inc., a startup dedicated to industrializing the capabilities of polymer informatics. Their cloud-based software is already being adopted by various sectors, enhancing the efficiency and cost-effectiveness of material design processes. By enabling users to virtually design and predict the performance of materials, Matmerize is paving the way for broader application and adaptation of AI tools in materials science.

As researchers continue to refine AI methodologies, we are likely to witness an accelerated pace of discovery leading to the next generation of polymers that will tackle contemporary challenges. The integration of AI in materials science is not merely a trend; it represents a seismic shift in how we approach material design and research. The collaborative framework established among academia, industry, and technology continues to form a promising landscape, hinting at revolutionary advancements in materials application for years to come. Ultimately, the future of polymers stands at the intersection of innovation, sustainability, and advanced technology—driven by the innovative spirit exemplified by Georgia Tech’s program and its commitment to transforming possibilities into reality.

Leave a Reply