As summer temperatures soar, the quest for cooler outdoor attire has never been more pertinent. Athletes, construction workers, children at play, and beachgoers are all affected by oppressive heat that can lead to discomfort and health risks. While conventional textiles may reflect sunlight or expel body heat, many of these products rely on specialized materials and complicated production. Recent research from the University of Massachusetts Amherst, however, introduces an exciting alternative: a durable chalk-based coating that has shown the capacity to cool the air beneath treated fabrics by as much as 8 degrees Fahrenheit.

The urgency for cooling fabrics arises due to the dual impact of sunlight and human-generated heat. As Trisha L. Andrew, a prominent chemist and materials scientist, points out, exposure to ultraviolet (UV) and near-infrared (near-IR) radiation increases bodily heat absorption. This notion anchors the research behind smart textiles intended to provide relief from such uncomfortable conditions. Traditional methods for achieving thermal comfort often involve either advanced synthetic materials with heavy chemical footprints or inherently high production costs. Thus, the search for a more sustainable and effective textile solution is imperative.

Undertaking this challenge, the research team, led by graduate student Evan D. Patamia, aimed to explore textiles that both deflect solar radiation and disperse body heat. This mechanism, termed radiative cooling, plays a pivotal role in ensuring comfort for those exposed to high temperatures. While previous efforts involved intricate synthetic particles or harmful chemicals—known as perfluoroalkyl substances (PFAS)—the goal became clear: create a natural, eco-friendly coating that could replicate these effects.

In contrast to the conventional approaches, the research team drew inspiration from ancient building techniques that employed crushed limestone to combat heat. The primary innovation lies in integrating calcium carbonate and bio-compatible barium sulfate into a polymer coating using a method called chemical vapor deposition (CVD). By using this efficient synthesis and application process, the researchers successfully adapted an age-old material for contemporary demands.

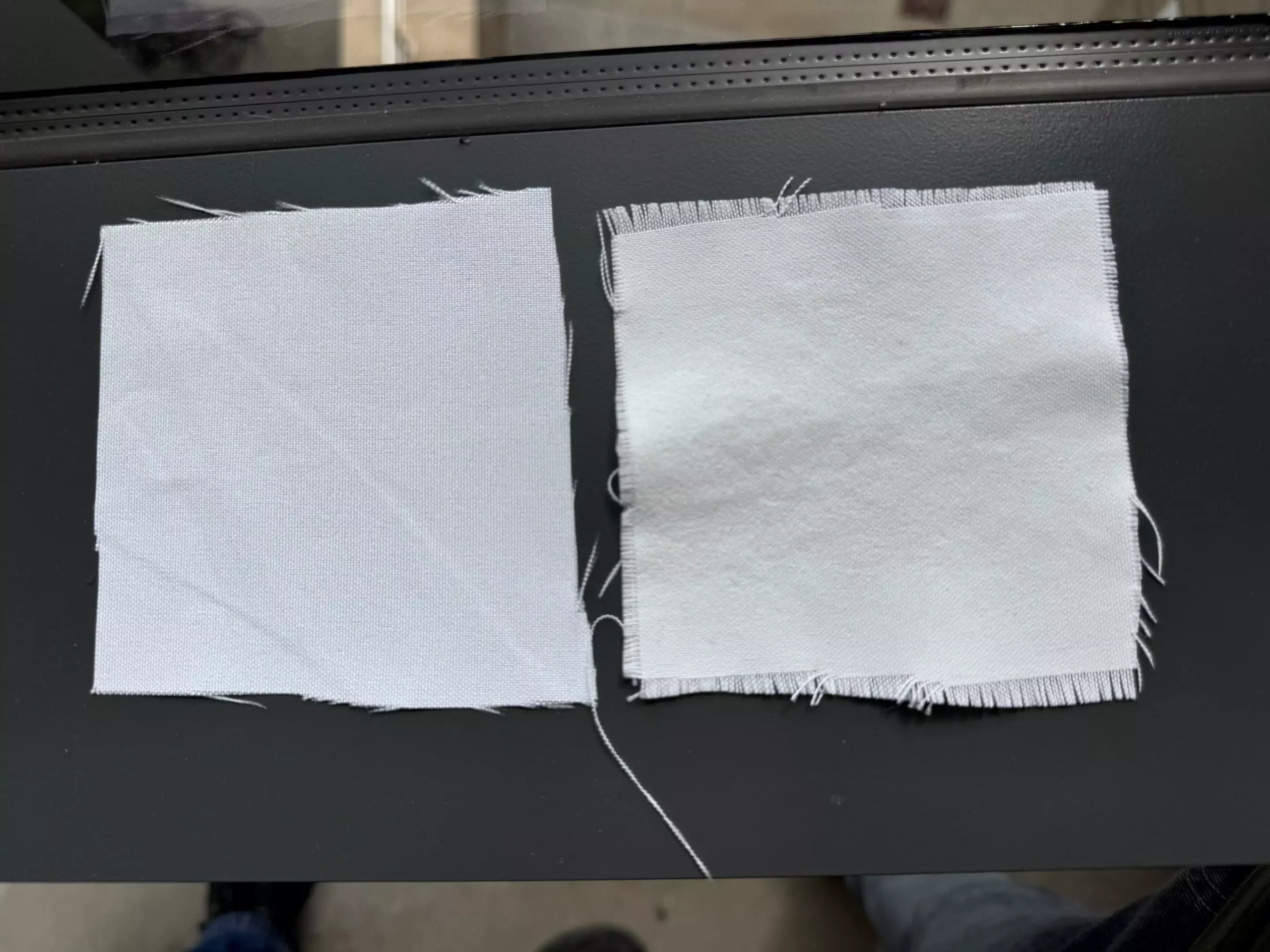

This innovative coating process efficiently places a thin polymer layer onto traditional fabrics, significantly reducing the environmental burden associated with textile treatments. The calcium carbonate particles serve the dual purpose of reflecting visible light and near-IR radiation, while barium sulfate efficiently bounces back harmful UV rays. More impressively, manipulations of the deposition cycles allow for customization of particle sizes, optimizing the fabric’s cooling capabilities through precise engineering.

Field trials showcased the promising potential of the chalk-based coating. When subjected to sun exposure on a sweltering day exceeding 90 degrees Fahrenheit, the air temperature beneath the treated fabric remained up to 8 degrees cooler than the ambient air. This cooling effect intensified, with variations reaching up to 15 degrees cooler compared to untreated fabrics. Such scientific findings not only harmonize with human comfort needs but also elevate the potential of this new coating to make outdoor environments more bearable.

Patamia emphasized the significant reduction in perceived heat. When positioned under the experimental fabric, individuals reported feeling significantly cooler than they would in the shade, illuminating the immediate applicability of this technology in various outdoor settings.

A critical consideration in any fabric innovation is its lifecycle and durability. Researcher Megan K. Yee undertook rigorous testing, simulating the effects of laundry and wear, confirming that the mineral-polymer coating maintained its structural integrity and cooling properties. This durability suggests that products developed from this technology could withstand the rigors of typical use, making it an alluring option for manufacturers and consumers alike.

Looking ahead, Andrew’s involvement in a startup represents another leap forward in translating laboratory innovations into mass-produced textiles. By refining the CVD process for larger fabric rolls, this technology holds the promise of becoming widely available. As Andrew notes, the appeal lies in the versatility of the coating; it can be applied to virtually any commercially available fabric, transforming standard attire into advanced cooling garments without relying on external power sources.

The intersection of traditional materials with modern technology creates an exciting prospect for the future of cooling fabrics. The application of a chalk-based coating has not only demonstrated tangible benefits but also navigates the complex ecological challenges faced by many contemporary textile solutions. As more industries explore these sustainable innovations, the promise of combating extreme heat and enhancing outdoor comfort becomes a palpable reality. In a world grappling with rising temperatures, these innovations could serve as simple yet powerful tools in the quest for comfort and well-being.

Leave a Reply