Plastic waste presents one of the most pressing environmental challenges of our time. Despite the abundance of solutions proposed, actual material recycling rates remain woefully low. This is particularly evident in the realm of chemical recycling, which can convert consumed plastics back into usable raw materials. At the forefront of addressing this urgent issue is a research team led by Professor Kotohiro Nomura from Tokyo Metropolitan University, who have introduced a groundbreaking method for the depolymerization of polyethylene terephthalate (PET).

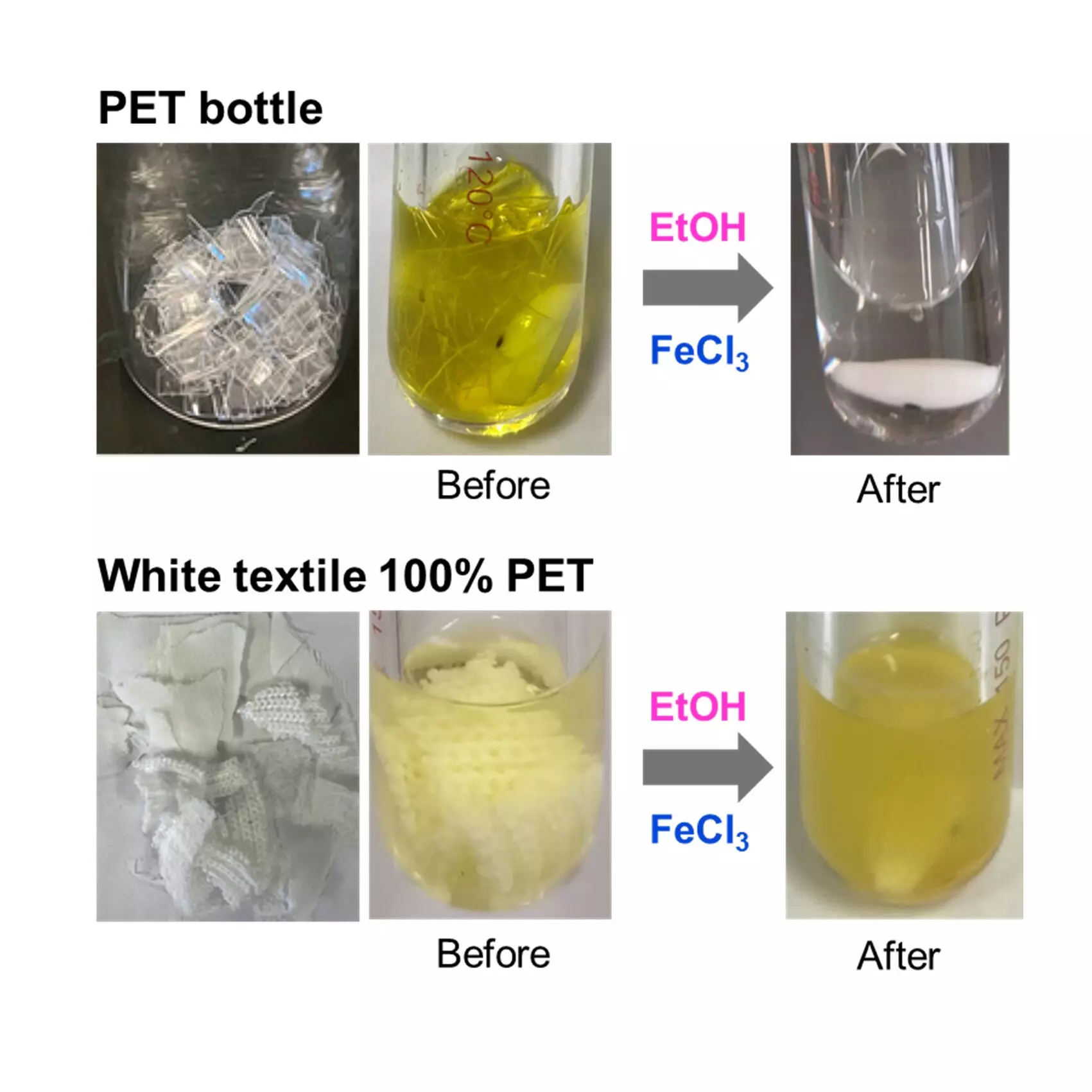

The study, published in the journal *Industrial Chemistry & Materials*, centers on a novel chemical process that employs alcohols in combination with a cost-effective catalyst: iron trichloride (FeCl3). This approach presents a significant shift from conventional methods that typically require elevated temperatures and harsh acidic or basic conditions for effective recycling. Instead, Professor Nomura’s technique operates within a much more manageable temperature range of 160°C to 180°C, demonstrating impressive catalytic efficiency.

Utilizing ethanol as an alcohol for the depolymerization process, the team achieved remarkable reaction selectivity, yielding diethyl terephthalate (DET) and ethylene glycol (EG) with a staggering efficiency rate of 98-99%. This high selectivity is crucial, as it allows for the effective recycling of PET materials while minimizing unwanted byproducts.

Iron trichloride stands out not only for its availability but also for its performance, which rivals that of more expensive titanium catalysts previously used for such processes. The breakthrough represents not just a technical achievement but a significant step towards making recycling of textiles and plastic waste more viable and sustainable. By enabling the selective depolymerization of PET from textile mixtures, the method demonstrates the potential to recover cotton fibers intact—thereby addressing multiple facets of textile waste management.

This resonates particularly in a time when global attention is focused on the challenge of managing mixed textile waste composed of polyester and cotton. The ability to extract valuable materials from such mixtures effectively underlines the method’s industrial applicability.

The innovation presented by Nomura and his team offers a promising beacon of hope in the quest for a more circular economy. By creating a method for the chemical recycling of PET that is both straightforward and efficient, the research paves the way for broader implementation and adoption within the waste management industry. The implications of such advancements extend well beyond local economies; they offer sustainable pathways for global waste reduction and resource management.

As industries look to achieve ambitious sustainability goals, the scalability of this method will be critical. It provides a framework for transforming an environmentally harmful waste stream into valuable materials while promoting the principles of recycling and resource efficiency. In doing so, it embodies a significant step towards mitigating one of the most daunting environmental challenges we face today.

Leave a Reply