The discovery of work hardening has its roots deeply embedded in ancient metallurgy, with blacksmiths during the Bronze and Iron Ages understanding the beneficial effects of deforming metals. This age-old practice of manipulating metal through techniques such as hammering or bending led to enhanced material strength. Although this phenomenon—termed work or strain hardening—has been applied extensively across various modern manufacturing sectors, including automotive and construction, a significant knowledge gap remained regarding its real-time mechanisms. This article examines a groundbreaking study from Harvard’s School of Engineering and Applied Sciences that provides fresh insights into this fundamental process, potentially transforming material science.

Historically, work hardening has played an integral role in shaping the way materials are utilized in engineering and manufacturing. From the ancient blacksmith forging swords to contemporary industries refining car frames and power lines, the strength derived from deformation has been paramount. However, it wasn’t until now that scientists could observe these mechanisms in real time rather than through post-deformation structural comparisons. The research conducted by Harvard’s team marks a significant milestone in comprehension, unveiling the intricate dynamics at play during work hardening.

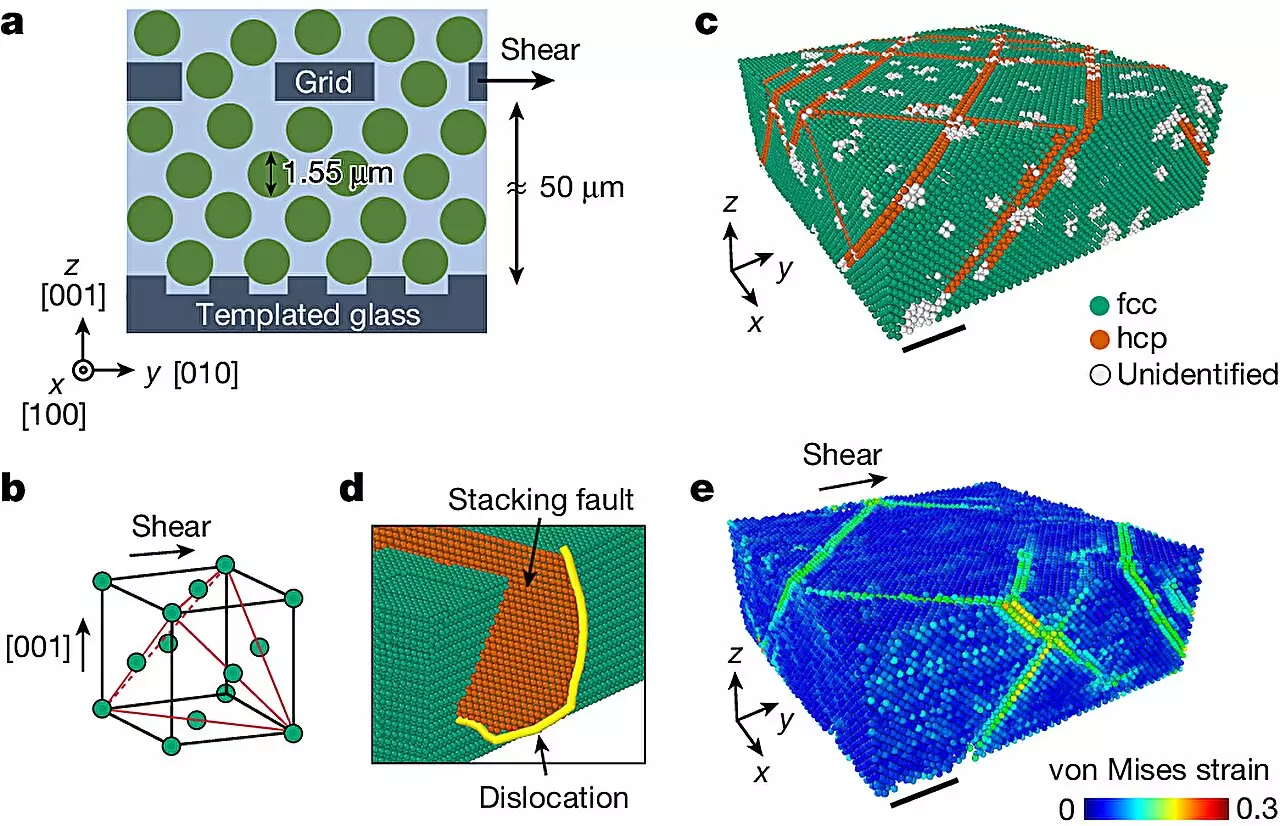

One of the primary challenges scientists faced was the inability to observe metallurgical changes as they occurred. Metal atomic structures could only be inspected in a static manner using electron microscopy, which left a comprehensive understanding of the process unfulfilled. Researchers were aware that dislocations—imperfections within a crystal structure—played a role in hardening, but specific details about how these defects interacted during deformation remained elusive. Thus, a fresh approach was necessary to analyze these fundamental interactions in real-time effectively.

To navigate these complexities, the research team utilized colloidal crystals, which are particles significantly larger than atoms—about 10,000 times larger—capable of forming their own unique crystalline structures in high concentrations. These colloidal systems share similar structural characteristics with their atomic counterparts, including phase transitions and the nature of defects. Remarkably, while colloidal crystals are remarkably soft—up to 100,000 times softer than gelatin—this study uncovered their potent ability for work hardening.

Using high-resolution confocal optical microscopes, researchers examined the movements of individual colloidal particles under strain. The results were astonishing. Contrary to initial expectations, the colloidal crystals exhibited pronounced work hardening, even surpassing that of conventional metals such as copper and aluminum in strength, when size variations among particles were considered.

Examining the Mechanisms Behind Work Hardening

The study unwrapped various insights into how colloidal crystals achieved this unexpected resilience. It revealed that the intricate interactions and entanglements among the dislocation defects primarily governed the work hardening process. Most importantly, this new understanding points towards a universal principle applicable to materials well beyond the realm of colloidal systems, opening the door for advancements in material science.

The researchers concluded that these observations highlighted the significance of particle geometry and defect density in determining material strength. The ability of these soft colloidal crystals to accommodate an exceptionally high density of defects was a vital contributor to their formidable work-hardened state. Thus, even materials traditionally perceived as weak can, under the right conditions, rival the strength of classic metals.

The implications of this research extend far beyond academic curiosity; they pose exciting possibilities for designing new materials across various fields. Understanding the fundamental principles that govern work hardening lays the groundwork often needed for future engineering innovations. Whether through developing lighter and stronger components for aerospace applications or enhancing structural elements for construction, the revelations from this research stand to impact multiple disciplines.

This exploration of colloidal crystals has not only illuminated essential mechanisms underlying work hardening but also fostered a better understanding of material science as a whole. It is with continued research into these soft yet strong materials that we can expect further advancing techniques, ushering in unprecedented developments in material design and industrial applications. The ancient practice of blacksmithing now finds itself, unexpectedly, linked with cutting-edge research at premier institutions—and one can only

wonder what future advancements await in the realm of materials science.

Leave a Reply