In our quest for advanced materials, nature continues to serve as the ultimate source of inspiration. Biological systems, exemplified by sea sponges, exhibit remarkable capabilities in designing structures that boast strength while remaining flexible. This unique combination is achieved via layered growth patterns that blend hard minerals with softer components, resulting in materials that can withstand external stresses without succumbing to fracture. As the celebrated researcher Nancy Sottos points out, “Nature has a way of turning brittle materials into tough ones through intricate patterning.” This intrinsic ability of natural organisms serves as a benchmark for scientists and engineers striving to emulate similar resilience in synthetic materials.

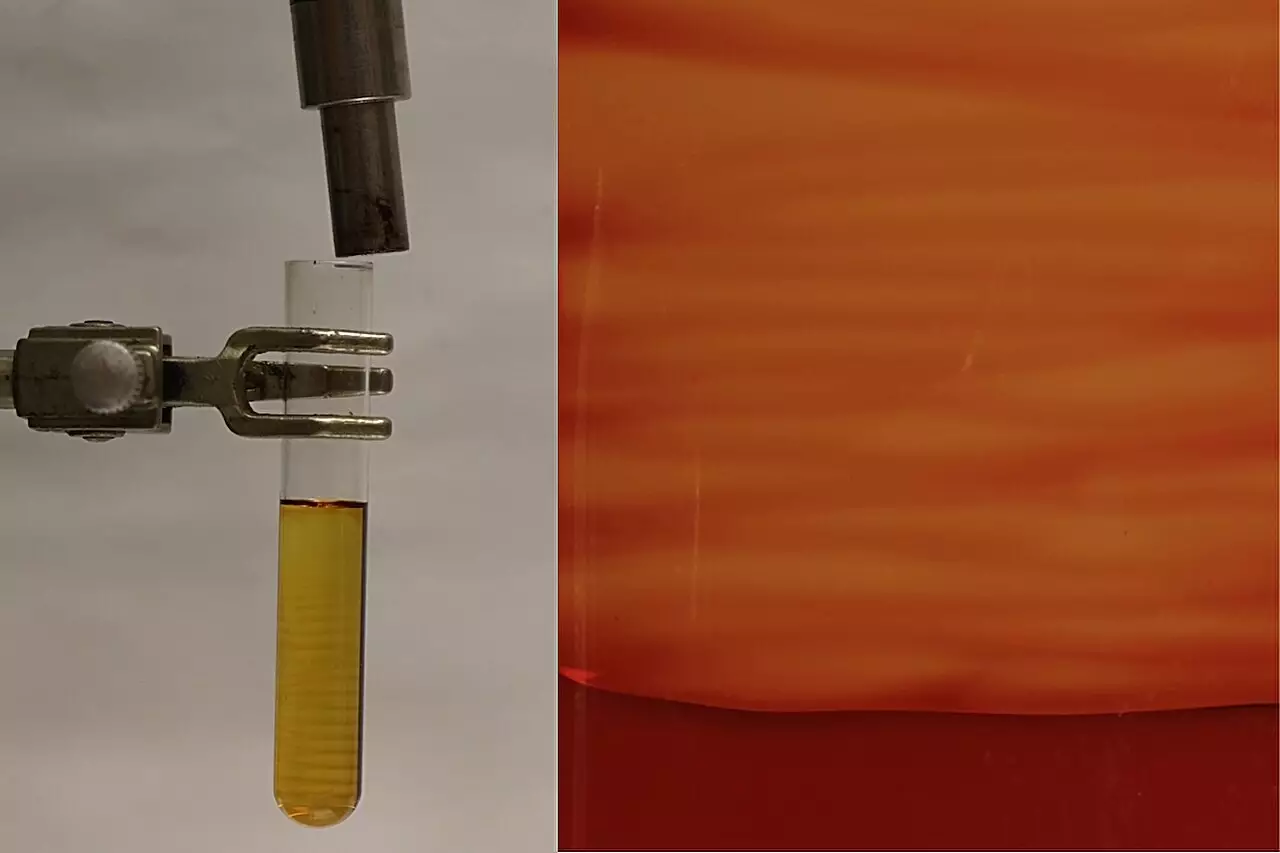

A groundbreaking study recently published in Nature highlights the achievements of Sottos and her colleagues in mimicking nature’s design principles through a process known as frontal polymerization. This method employs heat to initiate chemical reactions that result in strong polymer chains, effectively allowing the team to create biologically inspired materials with improved toughness. What’s compelling is how this study elevates earlier work, presenting a refined technique that enables the controlled creation of crystalline patterns within materials. This innovation leads to significant enhancements in both durability and strength, crucial attributes for modern engineering applications.

Jeff Moore, a pivotal figure in this research, emphasizes the difference between nature’s spontaneous patterns and the precise methods typically employed in synthetic material production. “Our work demonstrates a new frontier—patterning materials without molds or milling, resulting in unique properties that arise from this added structure,” he asserts. Here, we see a shift from traditional manufacturing techniques to a new paradigm that allows for the organic formation of material properties, which could have profound implications for future applications in aerospace, construction, and other fields requiring sophisticated material performance.

The success of this innovative technique did not arise in isolation. It is a testament to the power of interdisciplinary collaboration, particularly within the environment fostered by the Beckman Institute. Different academic backgrounds converged to explore the complexities of patterned materials; for instance, Cecilia Leal employed X-ray scattering techniques to visualize the orientation of polymer chains throughout the material. This sophisticated analysis was vital for understanding how the microstructure impacts material performance.

Additionally, Philippe Geubelle’s expertise in modeling the thermochemical processes provided insights into the instabilities that led to the materials’ unique heterogeneity. This collaborative spirit is echoed by Geubelle when he states, “The close collaboration between experimentalists and modelers, and between researchers from mechanics, materials science, and chemistry was instrumental to the success of this project.” Such an environment encourages creativity and drives innovation, making it possible to navigate the intricacies of material synthesis in ways that would be otherwise unfeasible.

As research continues to unfold, the implications of this work are vast. Industries increasingly require materials that not only meet high-performance standards but also demonstrate resilience under varying conditions. With the integration of nature-inspired techniques, the development of materials that transition between soft and hard states could revolutionize sectors ranging from aerospace to consumer goods.

The advancements achieved by Sottos and her team not only underline the importance of looking at natural processes for inspiration but also mark a new direction in materials science. Future research could witness further iterations of this method, fine-tuning the chemical formulations to yield even greater variations in material properties. Artificially engineered materials that mimic the resilience of biological structures promise to enhance everything from our infrastructure to electronic devices, pushing the boundaries of what synthetic materials can achieve.

The interplay of nature and science, exemplified by the work of the Beckman Institute team’s approach to material design, opens up a wealth of possibilities. Understanding and integrating complex biological patterns could lead to a new era of intelligent materials that adapt to their environments, embodying the resilience seen in nature itself. As we embrace this confluence of biology and engineering, the future looks promising, filled with innovative solutions to some of our most pressing material challenges.

Leave a Reply