As the world steadily shifts towards more sustainable energy solutions, the demand for efficient and reliable battery systems has soared. Among these, sodium-ion batteries are gaining traction as a promising alternative to lithium-ion batteries. This is largely driven by their capacity to utilize sodium (Na), an element abundantly available and found primarily in common salt. Research stemming from South Korea showcases innovative advancements in preparing hard carbon anodes for sodium-ion batteries, pushing the boundaries of energy storage technology.

The innovative method developed by a research group led by Dr. Daeho Kim and Dr. Jong Hwan Park introduces a microwave induction heating process capable of preparing hard carbon anodes in an astonishingly short time of just 30 seconds. This rapid fabrication process not only enhances operational efficiency but also points to a stride towards overcoming the conventional limitations associated with sodium-ion batteries, such as their relatively lower energy density and shorter lifespan.

Sodium-ion batteries present multiple advantages over their lithium counterparts. The accessibility of sodium leads to lower costs in extraction and refinement, while also ensuring that battery production can be more energy-efficient and environmentally friendly. Furthermore, the less reactive nature of sodium translates into enhanced electrochemical stability—a key factor that enables fast charging capabilities and reliable performance even under variable temperature conditions.

Yet, despite these compelling benefits, researchers face considerable challenges in the manufacturing process, particularly regarding the need for hard carbon as an anode material. Unlike naturally occurring graphite, which is standard in lithium-ion batteries, hard carbon must be synthesized due to its necessary properties for accommodating larger sodium ions. This is where the conventional carbonization process, an intricate method requiring high temperatures and prolonged heating, presents both economic and environmental hurdles that have hindered broader commercialization.

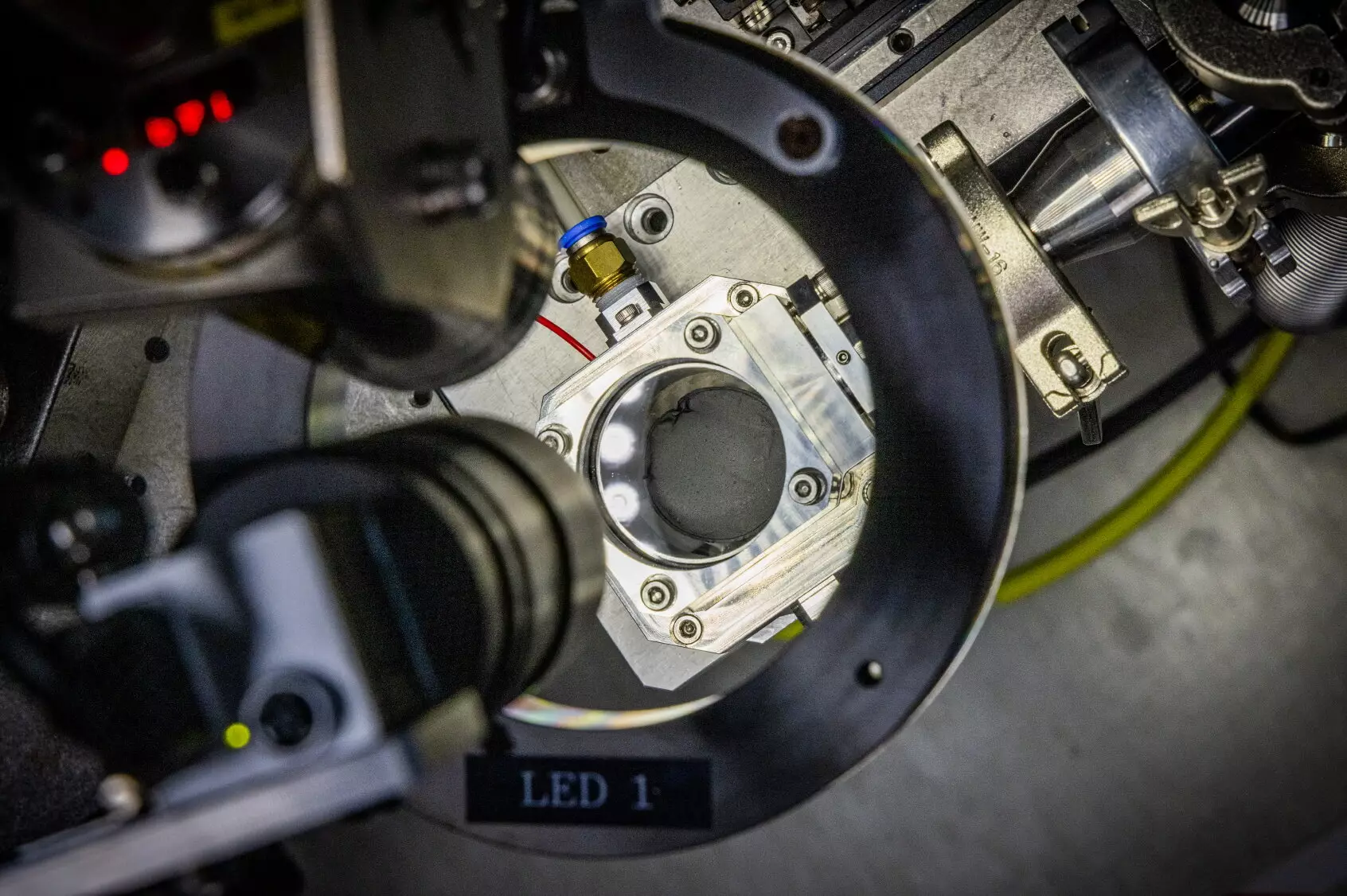

In addressing the challenges posed by traditional carbonization, the research group has embraced microwave induction heating—a method that utilizes principles reminiscent of everyday microwave ovens. By configuring this solution, the team ingeniously combined polymers with conductive carbon nanotubes to create films. Upon exposure to microwave fields, these films undergo selective heating, hitting temperatures exceeding 1,400 degrees Celsius in a fraction of the time typically required.

This remarkable achievement not only accelerates the production of hard carbon anodes but also maintains uniform heating across the materials, a feat supported by years of developmental research at the Korea Electrotechnology Research Institute (KERI). The institute has garnered recognition for its leading role in carbon nanomaterial technology, effectively contributing to innovations in various industry sectors including displays and semiconductors.

At the heart of the research success lies a unique technique termed “multiphysics simulation.” This innovative approach allows the research team to comprehensively understand the intricate processes that take place when electromagnetic fields interact with nanomaterials. The published findings in the Chemical Engineering Journal highlight the collaborative efforts, including contributions from student researchers Geongbeom Ryoo and Jiwon Shin.

As Dr. Jong Hwan Park notes, the growing interest in safer battery solutions—especially in light of recent incidents concerning electric vehicle fires—supports the urgency for sodium-ion batteries that perform efficiently under various conditions. The microwave induction heating technology paves the way for overcoming the efficiency and cost barriers associated with the carbonization process, thus propelling the commercial viability of sodium-ion batteries.

With a domestic patent application successfully completed, KERI is set to capture the interest of major players in the energy storage materials industry. Anticipating potential technology transfer deals with industry partners, the research team aims to further enhance the performance of their hard carbon anodes while developing methods for mass production that can scale up to large-area films.

Moreover, the implications of their microwave induction heating technology extend beyond sodium-ion batteries. The researchers envision its potential application in other fields, particularly in all-solid-state batteries that demand high-temperature sintering—a notion that warrants deeper exploration in future research initiatives.

The advancements in sodium-ion battery technology spearheaded by KERI not only represent a significant leap forward in energy storage solutions but also underscore the critical importance of innovative methodologies in addressing contemporary challenges in battery production and performance. The path ahead promises dynamic transformations in how we harness energy sustainably, with continued research and collaboration poised to bring these futuristic technologies to fruition.

Leave a Reply