As the global community increasingly grapples with the ramifications of climate change, the demand for sustainable technology has surged. One area of technology radically affected is battery production, particularly with lithium-ion batteries that fuel everything from electric vehicles to mobile devices. Traditional batteries utilize materials such as polyvinylidene fluoride (PVDF) binders and lithium hexafluorophosphate (LiPF6) salts, both of which are fluorinated compounds. These components present significant environmental challenges due to their toxicity and non-biodegradability, with PVDF systems posing risks of releasing hazardous chemicals like hydrogen fluoride (HF) during operation or degradation. As regulations tighten—especially within the European Union—there is an urgent need for innovative, eco-friendly alternatives that can enhance performance while adhering to environmental standards.

In light of these challenges, a pioneering research team from POSTECH and Hansol Chemical has introduced a transformative battery system utilizing non-fluorinated materials. Their findings, recently published in the Chemical Engineering Journal, present a groundbreaking lithium perchlorate (LiClO4) electrolyte and aromatic polyamide (APA) binder. This new system, referred to as “APA-LC,” is not only compliant with upcoming restrictions on hazardous substances but also exhibits improved performance metrics when compared to conventional fluorinated systems.

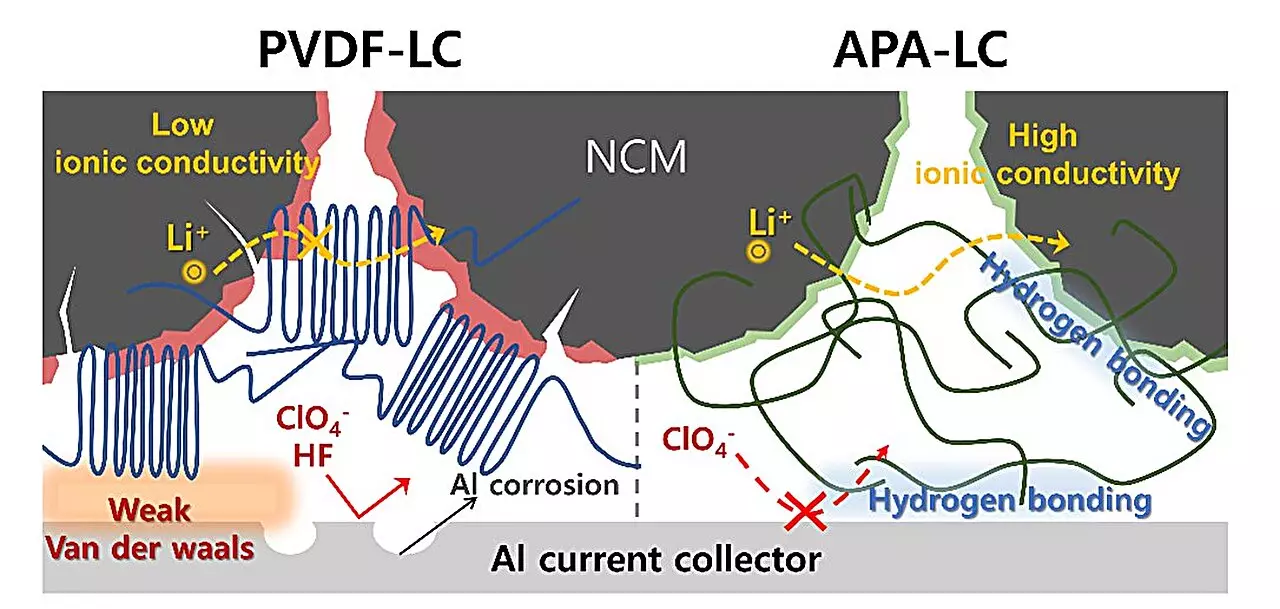

The APA binder plays a crucial role in establishing a robust chemical bond between the cathode’s active materials and aluminum current collectors. This enhancement minimizes electrode corrosion within the electrolyte—an achievement that promises increased lifespan and efficiency for battery systems. Similarly, the introduction of LiClO4, combined with lithium chloride (LiCl) and lithium oxide (Li2O), effectively lowers the energy barrier for ion migration. As a result, lithium ions can diffuse more readily, thereby facilitating higher output performance—an important consideration for fast-charging applications.

The research team has meticulously evaluated the APA-LC system’s performance, demonstrating noteworthy superiority over existing technologies. In rigorous tests, the new battery configuration maintained over 20% greater capacity retention after 200 charge/discharge cycles at a rapid rate—an impressive figure within a voltage range of 2.8-4.3V. This capacity for stability under stress exemplifies the outstanding potential of the APA-LC system, paving the way for widespread application in high-capacity pouch cells.

What sets this breakthrough apart is its feasibility for scalability while remaining entirely devoid of fluorinated compounds. The successful demonstration of a 1.5 Ah pouch cell not only highlights the system’s viability but also poses a challenge to existing benchmark technologies. As the market shifts toward sustainable solutions, this innovation could redefine product expectations within the battery landscape.

The emergence of the APA-LC system is not merely an academic achievement; it is positioned strategically in response to market dynamics that prioritize environmental compliance. Professor Soojin Park of POSTECH emphasizes the significance of this research by stating that their approach goes beyond mere substitution of materials—it fundamentally enhances capacity retention and stability. This progressive mindset aligns perfectly with global demands for greener alternatives in storage technology.

Young-Ho Yoon, Managing Director of Hansol Chemical’s Secondary Battery Materials Business, reinforced the commercial viability of this advancement. By preemptively addressing PFAS regulatory constraints, Hansol Chemical eyes significant growth opportunities within the increasingly competitive global cathode binder market. Projections estimate this market could reach KRW 1.7 trillion by 2026, offering substantial prospects for companies that can innovate responsibly.

The development of the APA-LC battery system emerges as a pivotal moment in the journey toward more sustainable energy storage solutions. By eliminating fluorinated components and introducing high-performing alternatives, this breakthrough not only mitigates environmental risks but also sets a new benchmark for battery performance. As researchers and industry leaders continue to forge this path, the commitment to sustainability will no longer be an optional add-on but a fundamental aspect of innovation in battery technology. The future appears promising as researchers like those at POSTECH and Hansol Chemical pave the way for responsible energy solutions that align with our global commitment to environmental stewardship.

Leave a Reply