When it comes to administering drugs intravenously, it is crucial to understand the science behind the different types of IV fluids. IV fluids are not simply composed of water, but rather a mixture of chemicals to ensure the solution remains isotonic. Osmosis plays a key role in this process, as water moves in and out of the cells in response to the concentration of chemicals dissolved in the blood plasma. Without the right balance of salts, sugars, nutrients, drugs, and proteins, the blood cells can shrink or expand, leading to potentially harmful effects on the body.

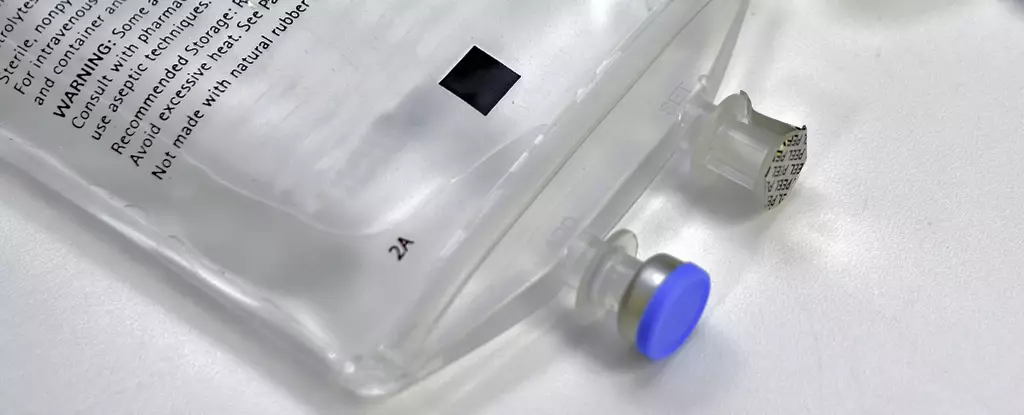

There are various types of IV fluids available for administering drugs, each with its own unique composition and purpose. Saline, which is a 0.9% solution of table salt, is one of the most commonly used IV fluids. In addition, there are fluids that contain glucose or a combination of salts like sodium, potassium, calcium, and magnesium. These different formulations are necessary because certain drugs are only stable in specific IV fluids. For example, administering a drug in the wrong fluid can cause it to become ineffective or even toxic, as seen with the chemotherapy drug cisplatin.

Recently, Australia has been facing a shortage of IV fluids, particularly saline and Hartmann’s solution. This shortage is due to a higher-than-expected demand and manufacturing issues. To address this issue, the Australian government has approved overseas brands of saline as a temporary solution. However, some drugs may not be compatible with alternative IV fluids, posing a risk to patients. This highlights the challenges of relying heavily on overseas manufacturers for critical medicines and the importance of developing local manufacturing capabilities.

The current shortage of IV fluids in Australia underscores the need to prioritize the development of local manufacturing facilities for essential medicines. By manufacturing off-patent drugs locally, Australia can create stable jobs, bolster the economy, and reduce its reliance on global drug suppliers. Moreover, having domestic manufacturing capabilities can mitigate the risks associated with medicine shortages and ensure a stable supply of critical drugs for the population.

As Australia continues to navigate the challenges of medicine shortages and supply chain disruptions, it is imperative that the government takes proactive steps to strengthen the country’s pharmaceutical manufacturing sector. By investing in domestic production facilities and supporting innovation in the pharmaceutical industry, Australia can enhance its healthcare system’s resilience and protect the health and well-being of its citizens. Ultimately, a sustainable and robust pharmaceutical manufacturing sector is essential for safeguarding public health and ensuring access to vital medicines in times of crisis.

Leave a Reply