The field of renewable energy has seen a surge in innovative technologies aimed at generating electricity sustainably in recent years. One of the emerging solutions to combat climate change is the conversion of excess or waste heat into electricity through thermoelectric power generation. This approach relies on materials with valuable thermoelectric properties that can harness the temperature difference to generate electrical potential.

New Strategies in Thermoelectric Power Generation

Researchers from Pohang University of Science and Technology and the George Washington University have introduced a novel strategy for designing thermoelectric materials based on copper selenide (Cu2Se). This new approach aims to overcome the challenges associated with traditional thermoelectric modules and optimize the design for high-power generation.

Designing Non-Cuboid Geometries

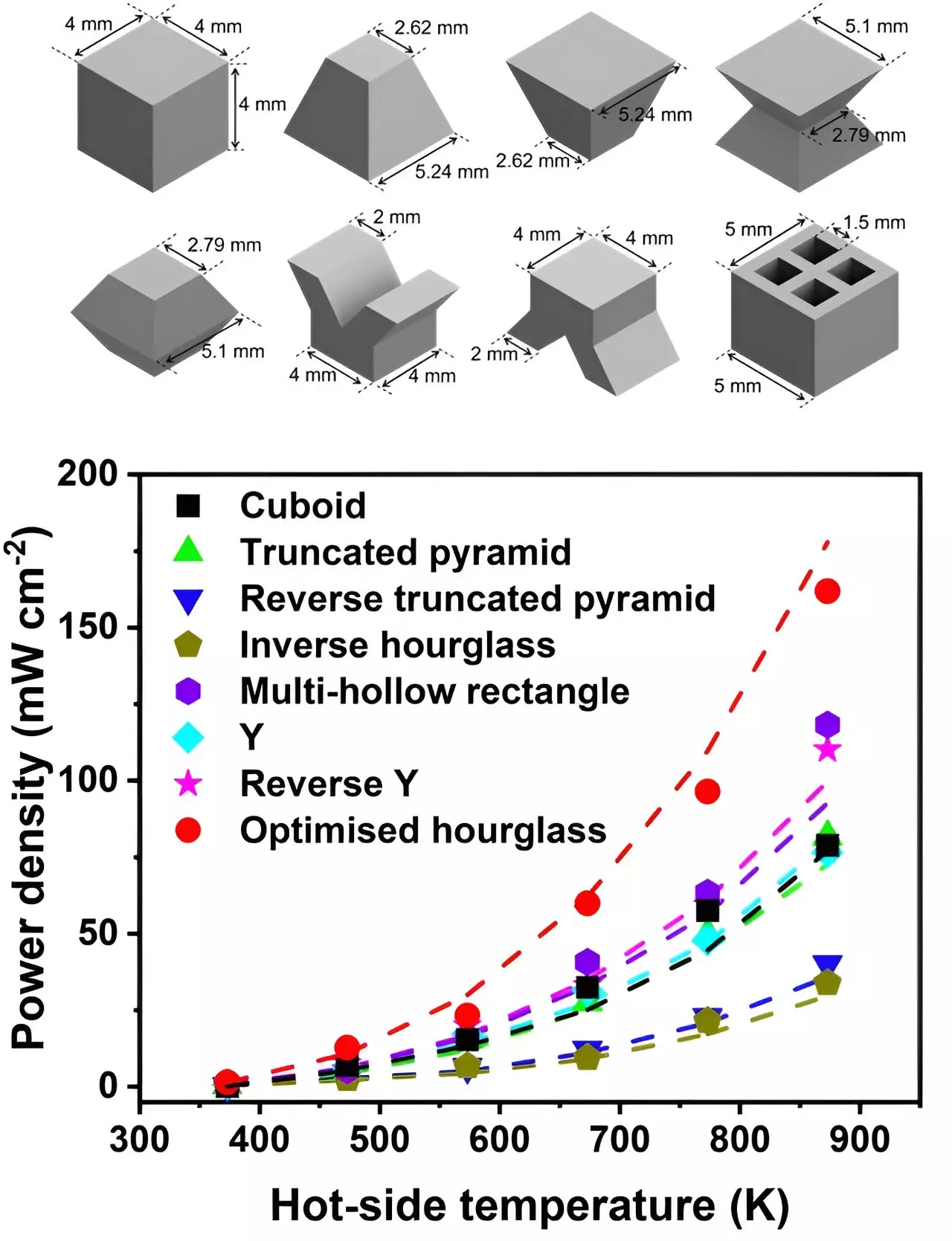

Traditionally, thermoelectric devices consist of p- and n-type semiconductor legs in a thermocouple configuration. The length and aspect ratio of these cuboid legs play a crucial role in maximizing power generation. However, researchers have explored the use of non-cuboid three-dimensional (3D) geometries to enhance thermal and electrical transport, potentially improving device performance.

The research team conducted simulations and experiments on different geometric designs of semiconductor legs using 3D finite element models and 3D printing techniques. Cu2Se was chosen as the model material for its high efficiency at elevated temperatures. The results showed that legs with an hourglass-shaped geometry exhibited the highest power generation and efficiency, outperforming cubic legs.

Impact of 3D Geometry on Power Generation

The study confirmed that the 3D geometry of thermoelectric materials significantly influences the electrical current they can generate. The controlled liquid-phase sintering technique enabled the formation of defects that reduced the thermal conductivity of Cu2Se, leading to enhanced ZT values. This finding highlights the potential of non-cuboid geometries in improving the performance of thermoelectric power generators.

The innovative approach to designing thermoelectric materials using 3D geometries opens up possibilities for enhancing the efficiency of power generation without altering the intrinsic properties of the materials. The research team plans to apply these non-cuboid geometries to different thermoelectric systems in future studies, such as segmented devices and Peltier cooling modules, to further explore their impact on performance.

The impact of 3D geometry on thermoelectric power generation is a promising avenue for improving the efficiency and sustainability of renewable energy technologies. By leveraging innovative design strategies and advanced manufacturing techniques, researchers can unlock the full potential of thermoelectric materials and contribute to the global transition towards a greener energy landscape.

Leave a Reply