Metallic materials have long been subject to a tradeoff between “strength” and “elongation,” where increasing one property often comes at the expense of the other. However, a collaborative effort between POSTECH and Northwestern University has introduced a groundbreaking technology that challenges this conventional wisdom. By designing an alloy that combines both high strength and high elongation, researchers have achieved a significant breakthrough in the field of materials science.

Yield strength is a critical factor in determining the durability and structural safety of a material. Typically, increasing yield strength involves reinforcing the microstructure of the material with precipitates. However, the introduction of these precipitates often leads to a reduction in elongation, creating a challenging trade-off between strength and ductility. This dilemma has hindered advancements in material design for decades.

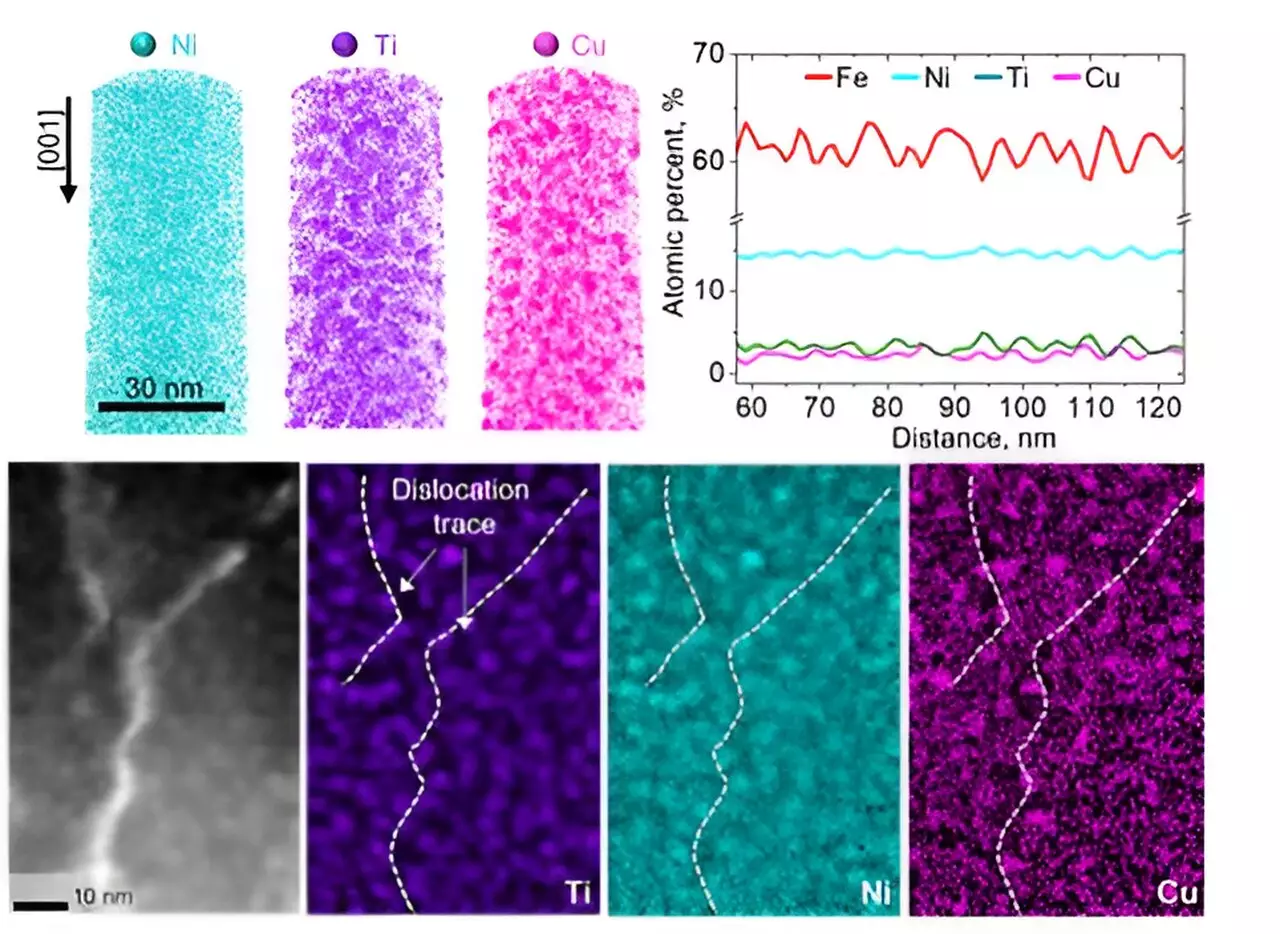

POSTECH Professor Hyoung Seop Kim’s team has introduced a novel approach to address this tradeoff, known as “spinodal decomposition.” This process involves the spontaneous separation of a solid solution into two distinct phases, resulting in nanoscale structures with regularly arranged atoms. By incorporating copper and aluminum into an iron-based medium-entropy alloy, the team triggered periodic spinodal decomposition at the nanoscale, leading to spinodal hardening and improved resistance to structural deformation.

Through this innovative approach, the resulting alloy demonstrated superior structural integrity compared to traditional alloys. The alloy achieved a remarkable yield strength of 1.1 GPa, representing a 187% improvement over the alloy without spinodal decomposition. Most notably, despite the significant increase in strength, the alloy maintained nearly the same elongation as before, showcasing the technology’s ability to enhance both properties simultaneously.

Future Implications and Opportunities

The introduction of this novel alloy technology opens up new possibilities for the design of high-performance materials with unprecedented strength and ductility. By overcoming the longstanding trade-off between strength and elongation, researchers are paving the way for the development of advanced materials with enhanced mechanical properties. The potential applications of this technology in various industries, from aerospace to automotive, are vast and promising.

The collaborative effort between POSTECH and Northwestern University has yielded a groundbreaking technology that challenges the traditional limitations of metallic materials. By leveraging spinodal decomposition to enhance both strength and elongation, researchers have achieved a significant milestone in materials science. This innovative approach not only offers a solution to a long-standing challenge but also paves the way for the development of next-generation materials with unparalleled mechanical properties.

Leave a Reply