Materials discovery has long been a challenging and costly process. The sheer number of possible materials, especially in fields like pharmaceuticals, has made the search for new materials a daunting task. With billions of possibilities for new materials composed of just a few elements, researchers have struggled to efficiently sift through the vast search space to find materials that meet their specific design goals. Traditional methods, which focus on maximizing or minimizing a single property, have proven to be too slow and inefficient in navigating complex design challenges.

A recent collaboration between computer science and materials science researchers at the Department of Energy’s SLAC National Accelerator Laboratory and Stanford University has led to a groundbreaking development in materials discovery. The team has developed an AI-based method that promises to revolutionize the way new materials are discovered. Published in npj Computational Materials, their research lays the groundwork for what they call “self-driving experiments,” where an intelligent algorithm guides the parameters for the next set of measurements at facilities like SLAC’s Linac Coherent Light Source (LCLS).

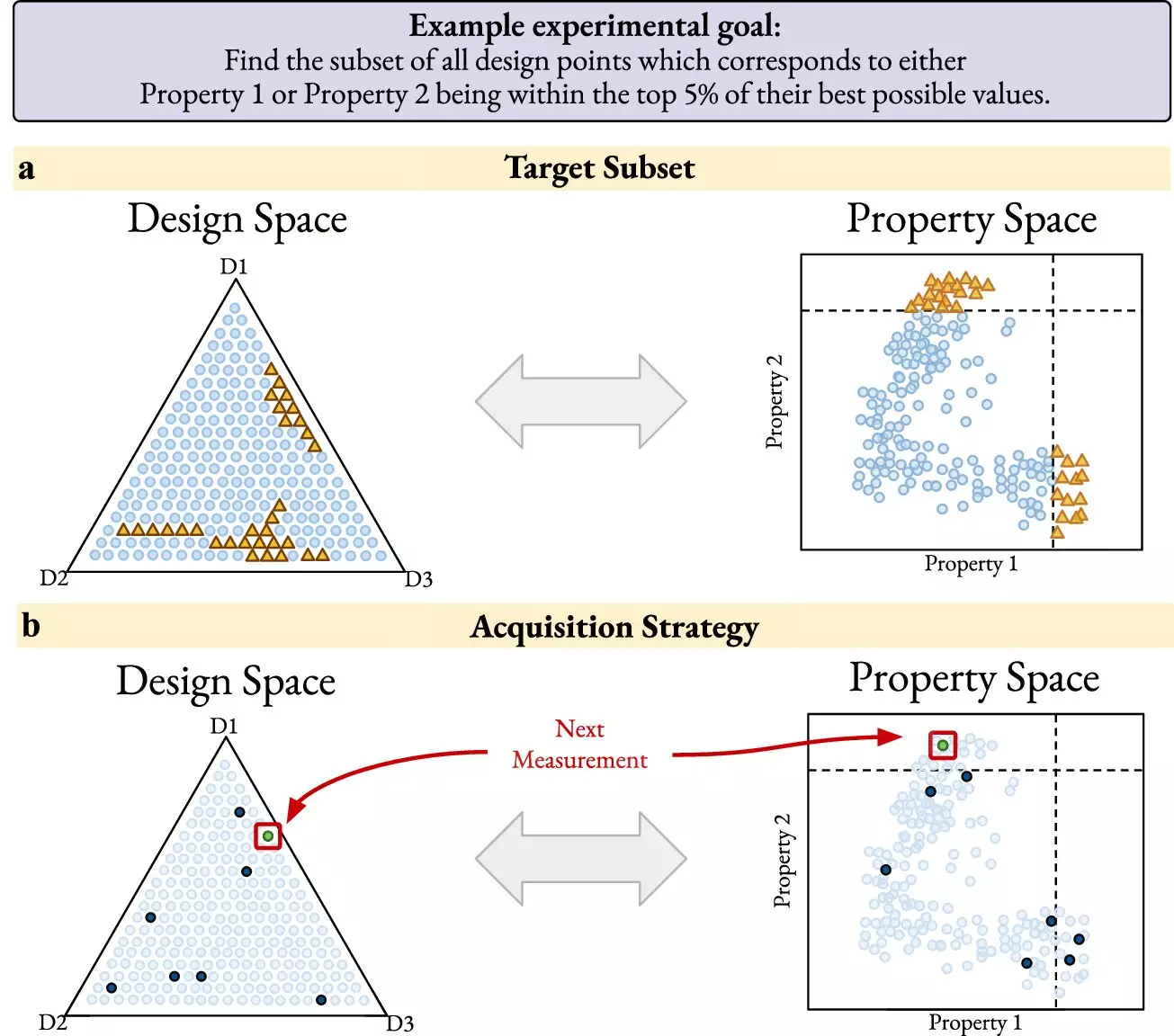

The new AI-based method not only streamlines the data acquisition process but also accelerates the discovery of new materials with potential applications in areas such as climate change, quantum computing, and drug design. By automatically converting complex design goals into intelligent data acquisition strategies, the AI algorithm learns and improves from each experiment, suggesting the next steps based on the data collected so far. This approach, known as Bayesian algorithm execution (BAX), simplifies the materials design tasks by enabling researchers to specify complex objectives in a user-friendly and open-source framework.

The implications of this new AI-based method are vast and far-reaching. In manufacturing, the ability to design materials with specific catalytic properties could lead to more efficient and sustainable production processes, reducing energy consumption and waste. The integration of new materials in technologies like 3D printing could enhance precision and sustainability in manufacturing. In healthcare, tailored drug delivery systems could improve the effectiveness of therapeutics while reducing side effects.

One of the key advantages of the new AI-based method is its user-friendliness and open-source nature, which allows scientists worldwide to adapt and utilize it for their research projects. This promotes collaboration and innovation on a global scale, fostering a community of researchers working towards the common goal of revolutionizing materials discovery. The multi-disciplinary collaboration between SLAC and Stanford highlights the power of combining advanced algorithms with targeted experimental strategies to streamline the process of discovering new materials.

The development of AI-based methods in materials discovery represents a significant leap forward in the field. By leveraging the power of artificial intelligence to navigate complex design challenges and accelerate the discovery of new materials, researchers are paving the way for a more efficient and sustainable approach to materials science. The integration of AI into experimental and simulation-based research projects demonstrates the versatility and effectiveness of this new method, offering endless possibilities for innovation and discovery in the realm of materials science.

Leave a Reply