Rechargeable solid-state lithium batteries have the potential to revolutionize the way we power our electronic devices. With enhanced energy density and improved safety features compared to traditional lithium-ion batteries, they offer a promising solution to the growing demand for long-lasting and reliable power sources. However, one major drawback of these advanced batteries is their impact on the environment, particularly when it comes to recycling. Current recycling methods are inefficient and result in the wastage of valuable materials. Fortunately, a team of researchers at Penn State University may have found a solution to this problem.

Traditionally, recycling lithium batteries has been a cumbersome process, with most of the core components ending up as a “black mass” that is difficult to separate and recycle. Solid-state batteries further complicate this issue due to the presence of solid electrolytes that become intermixed with other components during recycling. This mixing makes it challenging to recover valuable materials for reuse in new batteries. To address this challenge, the team at Penn State led by Enrique Gomez reconfigured the design of solid-state lithium batteries to facilitate easier recycling of all components.

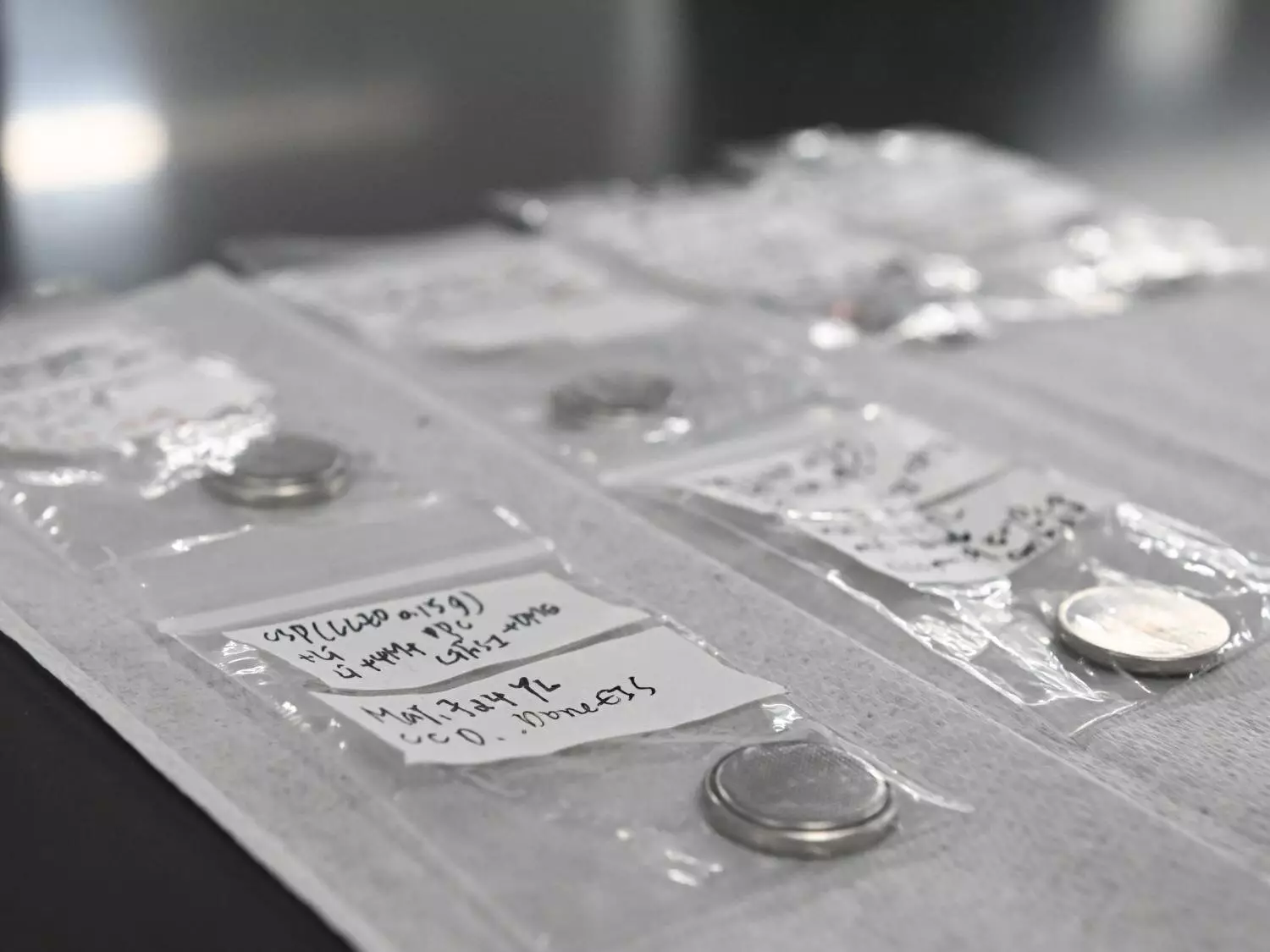

The researchers proposed an innovative solution by incorporating polymer layers between the electrode and the electrolyte in the battery design. These polymer layers can be dissolved during the recycling process, allowing for the easy separation of the electrode from the electrolyte. By avoiding the mixing of components, the researchers were able to recover metals and electrodes using cold sintering, a low-temperature process that combines powder-based materials into dense forms. This novel approach not only enables the recovery of valuable materials but also allows for the reconstruction of the battery for future use.

After successfully separating out the components, the researchers combined the recovered metals and electrodes using cold sintering to create a composite solid electrolyte powder. By reconstructing the battery with the polymer layers added back in, they were able to recycle the entire battery. Testing of the reconstructed battery showed that it retained between 92.5% and 93.8% of its original discharge capacity, demonstrating the viability of the recycling process. This breakthrough in battery recycling technology paves the way for the development of recyclable versions of solid-state lithium batteries in the future.

The research conducted by the team at Penn State represents a significant step forward in the development of sustainable battery technologies. By addressing the challenges associated with recycling solid-state lithium batteries, they have opened up new possibilities for the future of energy storage. As the demand for rechargeable batteries continues to grow, it is essential to consider the environmental impact of these technologies. By designing batteries with recyclability in mind, we can create a more sustainable energy future for generations to come.

Leave a Reply