Auxetic materials, with their ability to defy common sense by expanding when stretched and narrowing when compressed, hold tremendous promise for a wide range of applications. From bomb-resilient buildings to comfortable clothing, the possibilities seem endless. However, despite their unique properties, auxetic products have faced challenges in reaching the market. Researchers at the National Institute of Standards and Technology (NIST) and the University of Chicago are determined to change this narrative by introducing a new tool that simplifies and speeds up the design process for materials with auxetic properties.

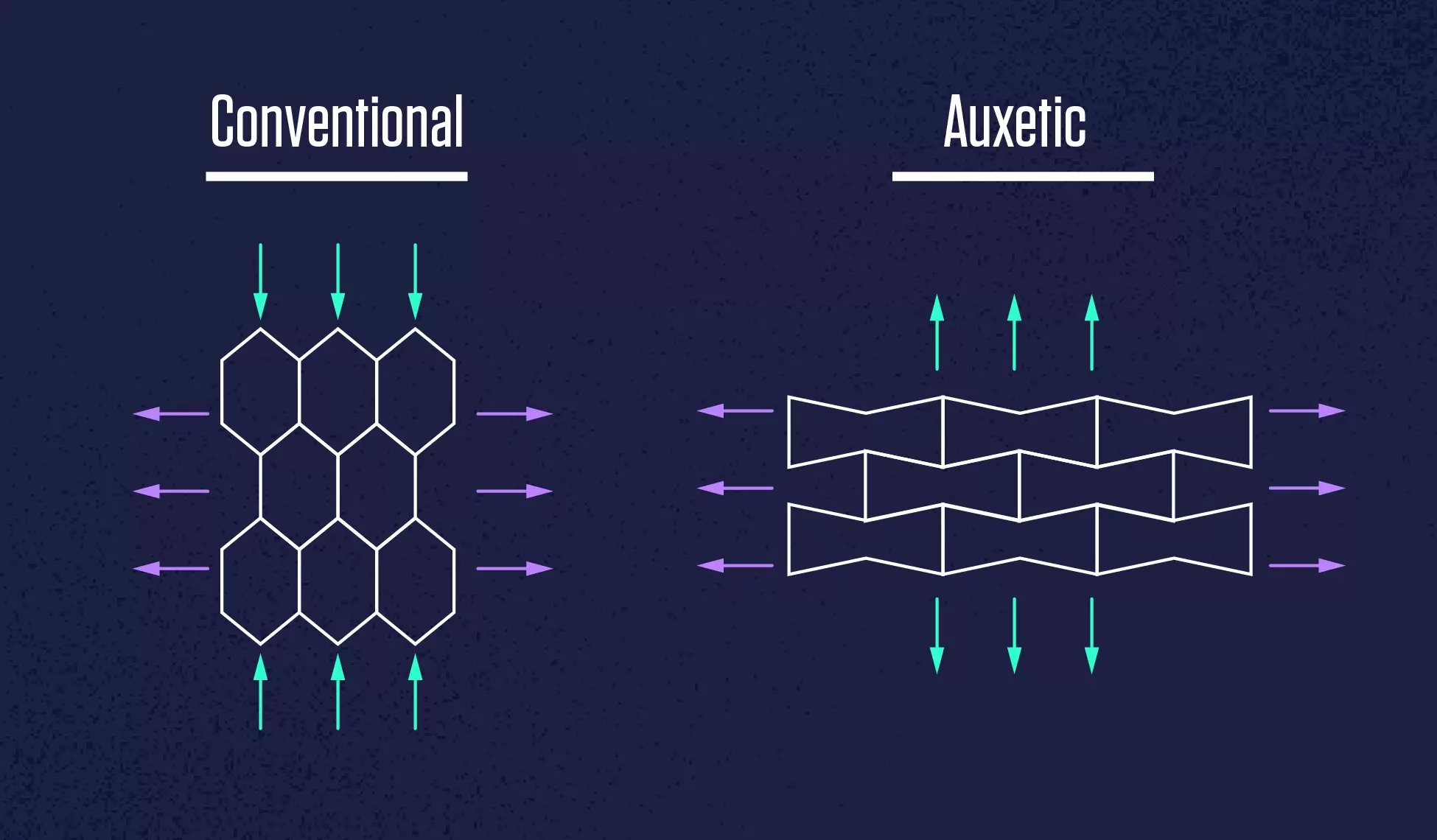

Poisson’s ratio plays a significant role in determining the behavior of elastic materials, including auxetics. Unlike conventional materials that exhibit a positive Poisson’s ratio, causing them to expand in other directions when stretched, auxetics have a negative Poisson’s ratio, resulting in the opposite effect. For example, when an auxetic material is compressed, it narrows in width instead of expanding. This unique behavior offers advantages in impact resistance, making auxetics ideal for applications where protection against collisions and explosions is crucial.

The potential applications of auxetic materials are vast and diverse. In the construction industry, auxetics could be used to enhance the resilience of buildings to withstand bomb blasts. In the automotive sector, auxetic materials could provide increased protection in car bumpers. Additionally, in everyday products like sneakers and clothing, auxetic materials could offer superior cushioning and comfort. For example, auxetic gel or rubber foam in sneaker insoles could provide better shock absorption, while auxetic fibers in clothing could distribute pressure more effectively across the body, reducing strain on the back, joints, neck, and shoulders.

The innovative design tool developed by NIST and University of Chicago researchers represents a significant leap forward in the field of auxetic materials. This “inverse design” algorithm allows users to specify the desired Poisson’s ratio for their material and generates an optimized structure accordingly. By fine-tuning the relationship between shape and volume, the algorithm enables the creation of auxetic materials with tailored mechanical properties that are not found in natural materials. This breakthrough in design opens up new possibilities for utilizing auxetic materials in diverse applications.

The collaborative efforts of theoretical, experimental, and computational scientists have resulted in a groundbreaking development in the field of auxetic materials. By enhancing the design and optimization of auxetics, researchers are paving the way for these materials to become more prevalent in everyday life. The patented algorithm and methodology, along with the implementation using 3D printing, represent a new era of innovation in material science. With continued research and advancements, auxetic materials are poised to revolutionize various industries and create new opportunities for design and engineering.

Leave a Reply